The Intertronics Blog

Management news

I left university and started a company. That was almost 45 years ago, and I have been running and been in sole charge of Intertronics ever since. It has been wonderfully rewarding responsibility. Some of you have already done the maths, and realise that not only is 45 years a long time, but that I […]

Read More

MMA structural adhesives in aerospace: an overview

Important properties for a structural adhesive in an aerospace application are strength, toughness, and flexibility, alongside temperature and environmental resistance. When choosing an adhesive, methyl methacrylate structural adhesives (MMAs) may be a good candidate to test, as these adhesives offer strength, toughness, and ease of use when bonding a broad range of materials, including metals, […]

Read More

Wheeling to Wiesbaden: cycle relay for Emmaus Oxford

We have, for a long time, offered every employee the opportunity to take an extra day of paid holiday to do something charitable, but people have always found it a challenge to find something that you can do as an ad-hoc bit of charity work for just one weekday. So, we have decided to make […]

Read More

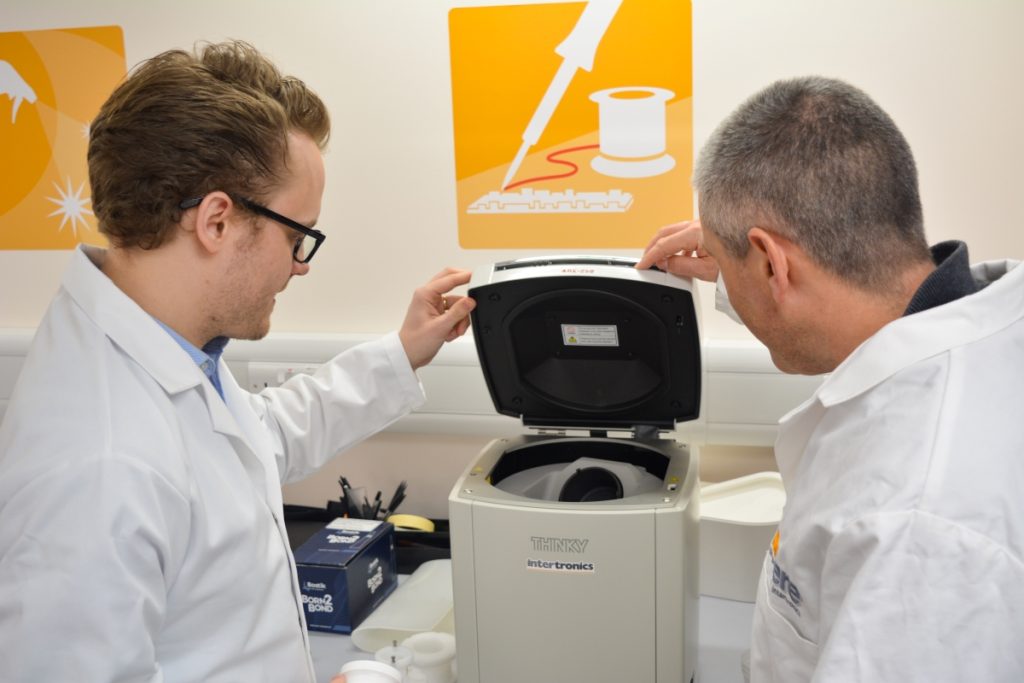

THINKY ARE-312: The next generation of high-performance planetary mixers

The THINKY ARE-312 is an industrial planetary mixer that can mix, defoam, and degas liquids, powders, and pastes in seconds to minutes to produce a uniform, homogenous mix. It is the upgrade to our very successful and popular flagship ARE-250, introducing several advancements, including computer connectivity with data logging, an improved user interface, and a […]

Read More

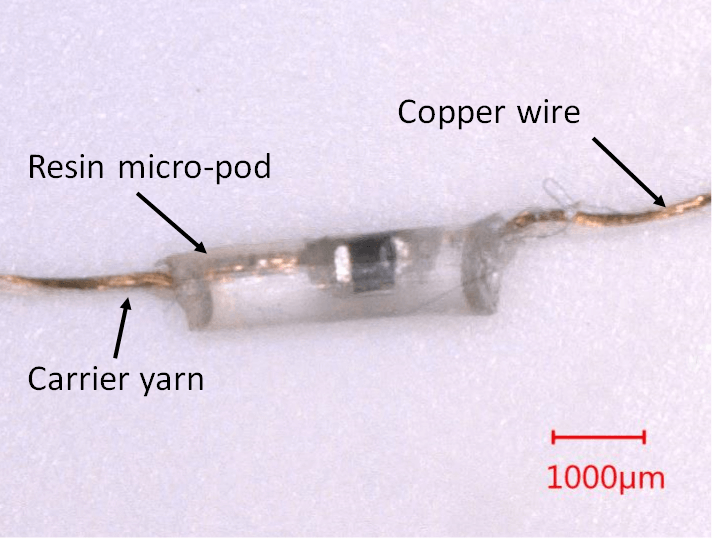

Wearables – adhesives and encapsulants for electronic textiles

Nature is a prestigious, peer-reviewed scientific journal known for publishing high-impact research across a broad range of scientific disciplines. Established in 1869, it is one of the world’s most influential scientific publications, covering fields such as biology, physics, chemistry, earth sciences, and more. Articles in Nature undergo rigorous peer review and are often groundbreaking, contributing […]

Read More

Adhesive for bonding polypropylene, polyethylene and more

Our partners SCIGRIP have announced the new SG400LSE MMA Methyl Methacrylate Adhesive for Low Surface Energy Plastics that creates fast and strong bonds with low surface energy plastics. SG400LSE has been tested on high-density polyethylene (HDPE), ultrahigh molecular weight (UHMW) PE, and homopolymer, copolymer and glass-filled polypropylene (PP) – bond strength testing results in substrate […]

Read More

adhere academy: storage and packaging of two-part structural adhesives

An adhesive’s data sheet will detail its storage requirements, but most two-part structural adhesives will last their whole specified shelf life if stored at room temperature in a cool dark place. There are some differences between the chemistries that may impact how they are packaged and stored. For example, both components of a two-part polyurethane […]

Read More

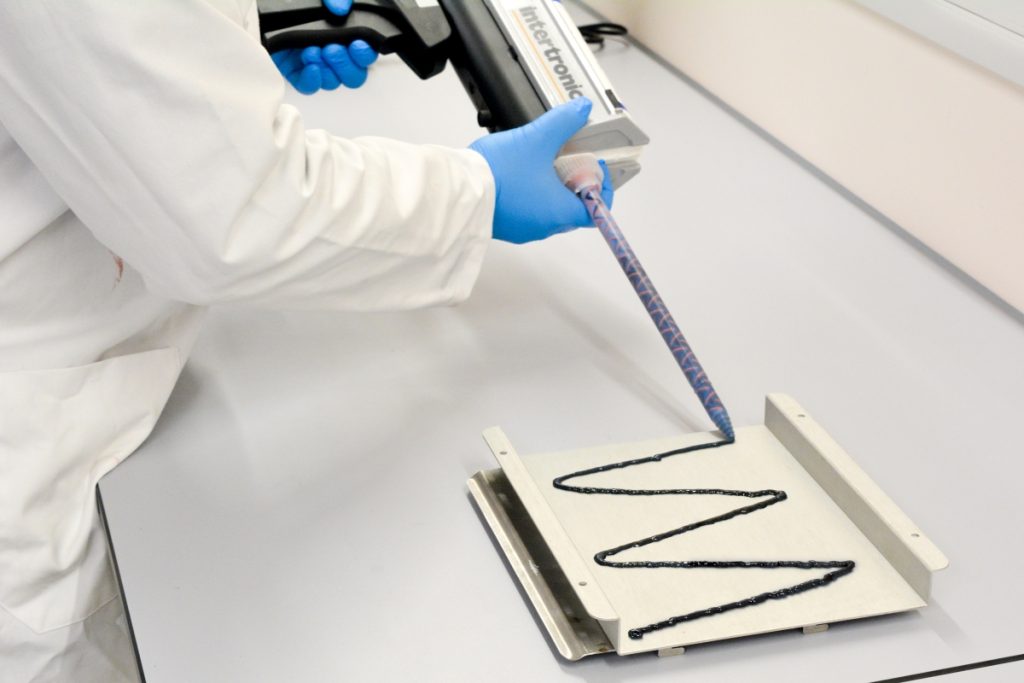

adhere academy: handling and processing two-part structural adhesives

It’s common for structural adhesive chemistries like epoxies, polyurethanes (PUs), and methyl methacrylates (MMAs) to have been formulated as two component parts – known as “two-part”, or “2K” adhesives. The two components of these adhesives are generally categorised as the resin (or base) and the hardener (or activator). Mixing the two parts initiates a chemical […]

Read More

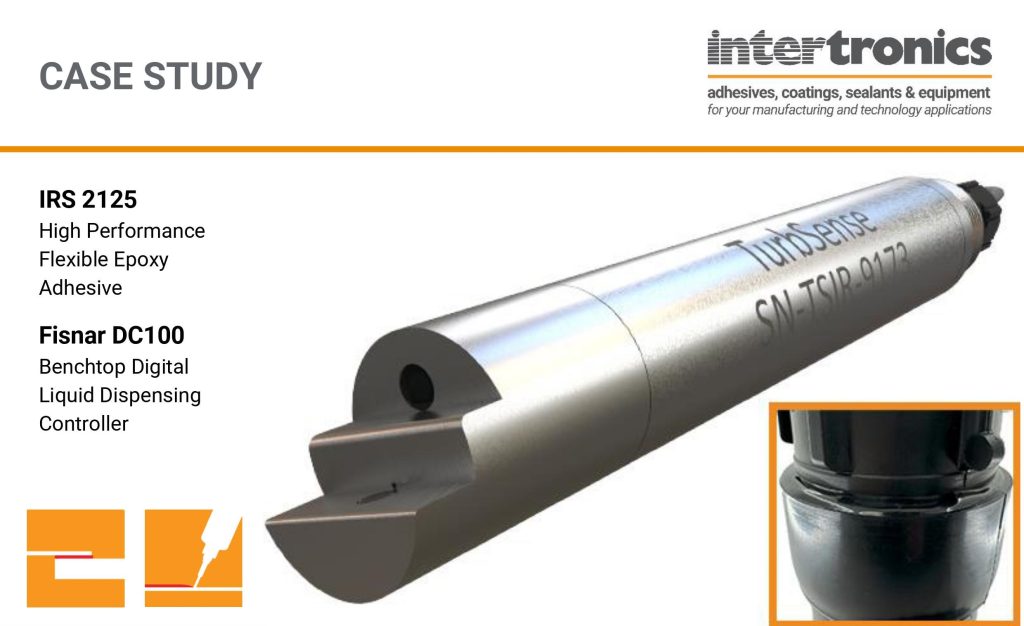

Case study: flexible epoxy drives performance

We are supplying Process Instruments (Pi), a water analyser instrument manufacturer, with our IRS 2125 High Performance Flexible Epoxy Adhesive. This versatile adhesive offered performance benefits as a thread locker on flow cells and an IP68 rated sealant on sensors. Pi manufactures and supplies water analyser instrument solutions that can reliably, continuously, and accurately measure […]

Read More

Attension User Day: Basics of Wettability

We recently acquired Dyne Testing Ltd, a supplier of surface testing and measurement products. One of our new partners is Biolin Scientific, and they are running a half-day online “Attension User Day” on June 3 2024 centred around understanding wettability and how wettability measurements can benefit your research and product development. There will be insights […]

Read More

Innovation & magic

Eight years ago, I wrote about this quote from Arthur C. Clarke: “Any sufficiently advanced technology is indistinguishable from magic.” That quote is still on the wall of our Technology Centre, even though we have moved into a bigger facility since I wrote the blog post. Then, I discussed how we demystify advanced adhesive technologies […]

Read More

Cyanoacrylate adhesive – a bad nuclear option

This week, I have been entertained on my drive to work by a BBC Sounds podcast called Glued Up: The Sticky Story of Humanity. Mark Miodownik, a materials scientist, engineer, broadcaster and writer at University College London, narrates five 15 minute episodes charting the journey of human progress through the sticky substances that have shaped […]

Read More

Sabbaticals, supportive cultures, and kangaroos – Liam’s story

Our colleague Liam Rogerson has recently returned from a 3-month sabbatical which saw him adventuring around Thailand, Vietnam, and Australia with his partner. Sabbaticals aren’t a common thing around Intertronics, but when Liam approached Teresa Nee, his manager, with the vague idea that he wanted to do a bit of travelling, not only did she okay […]

Read More

Intertronics acquires Dyne Testing Ltd

We have completed on the purchase of Dyne Testing Ltd, a leading UK manufacturer and supplier of surface measurement technology. Dyne Testing offers a range of measurement equipment for testing surface energy and tension, surface cleanliness, adhesion, and coating thickness, to improve quality and process control in various industrial applications. This aligns with Intertronics’ existing […]

Read More

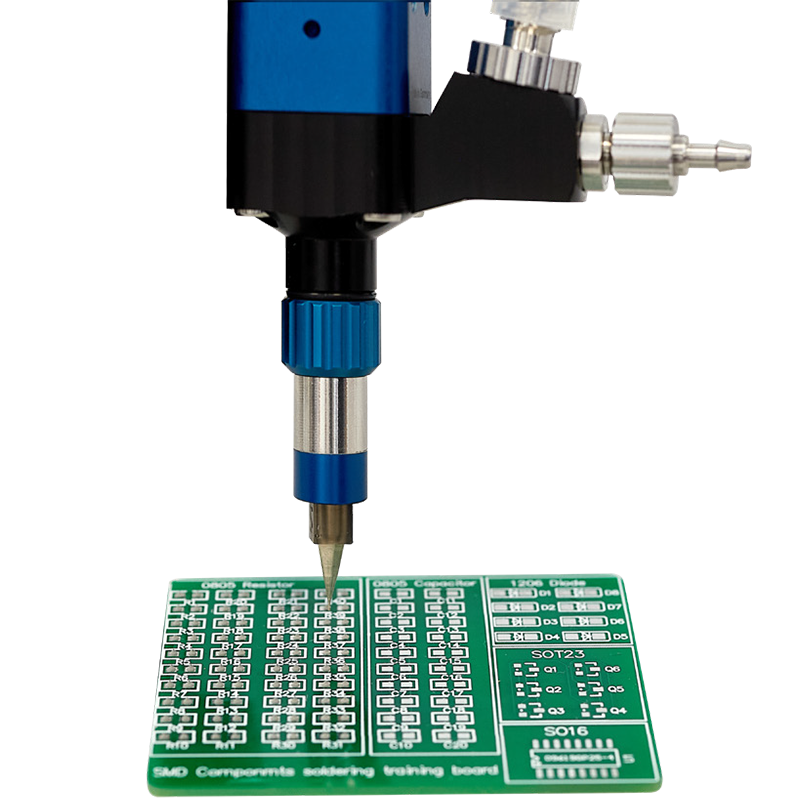

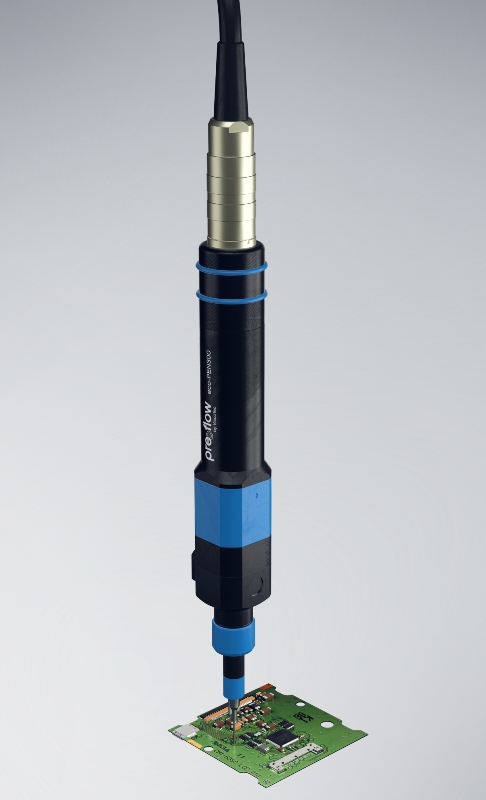

The most precise volumetric liquid dispenser now available

Designed specifically for small volume fluid or liquid dispensing applications, the eco-PEN XS 180 doses highly precise quantities of various materials in the nanolitre and microlitre ranges. The eco-PEN XS 180 is suitable for both line and dot dispensing, with bead widths starting from >0.1 mm, and an adjustable dispensing rate to suit the run […]

Read More

adhere academy: how to prepare two-part cartridges for dispensing

Many adhesives, sealants, and potting materials are packaged in two-part side-by-side cartridges, which are convenient for material application on the production line or in the field. Cartridges don’t require you to measure out materials in the correct ratio, and by adding the manufacturer’s recommended static mixing nozzle, fully mixed and homogeneous material can be dispensed […]

Read More

Structural adhesives selector guide now available

To help you find the right adhesive for your manufacturing application, we’ve launched a Structural Adhesive Selector Guide. The guide provides a full overview of five structural adhesive chemistries: methyl methacrylate (MMA), epoxy, polyurethane, UV curing, and cyanoacrylate. It covers 28 materials and their properties, curing considerations, compatibility considerations, and more. We have designed the […]

Read More

What is the difference between an adhesive and a sealant?

Our customers often use adhesives and sealants in their products, in a wide variety of applications. They can be seen as quite similar materials, and indeed have overlapping uses. Some adhesives are also used as a sealant; some sealants are also used as an adhesive. We even sell products which are termed “adhesive sealants”. But […]

Read More

Order online at intertronics.shop

For those who find it easier or preferable to order online, we have launched an online shop. Developed in response to customer feedback, intertronics.shop enables you to purchase a select range of our adhesives and consumables online. The online shop sits alongside our traditional consultative sales process — the full Intertronics range remains available by […]

Read More

Happy New Year, supporting our local community

Welcome to 2024. We look forward to working with you this year. At this time of year, our thoughts turn to those less privileged than us. We like to donate to local, smaller charities where what we give can make an appreciable difference. This year, we have donated to High Sheriff Sally Scott’s charitable fund, […]

Read More

15 Years of Learning – Kevin Brownsill

Our Learning and Development Manager, Kevin Brownsill, recently celebrated his 15-year milestone at Intertronics. Over the years, Kevin has seamlessly navigated various sales and technical roles, accumulating a staggering level of knowledge of our adhesives and equipment, including a worryingly encyclopaedic memory of part numbers. To mark his 15 years with the company, Kevin, who […]

Read More

Video: form strong, durable bonds in minutes with SCIGRIP MMAs

We have a new video featuring our Head of Technical: Learning and Development, Kevin Brownsill. He talks about our new range of methyl methacrylate adhesives (MMAs) from SCIGRIP. Catch it here:

Read More

Supporting our local foodbank this Christmas

With almost 90% of foodbanks operating nationwide experiencing increased demand last Christmas amid the cost-of-living crisis, the Intertronics team spurred into action with our annual collection. Throughout the month of December, we encouraged staff and visitors to donate food, toiletries, festive treats, and other vital supplies. Our very own Jimmy meticulously organized, packaged, and delivered […]

Read More

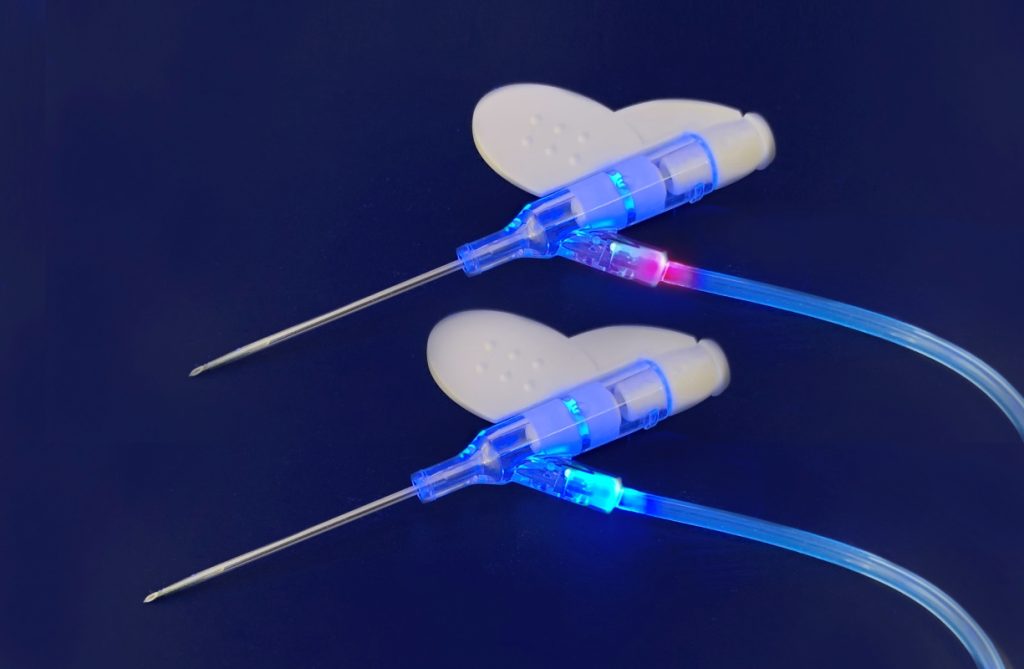

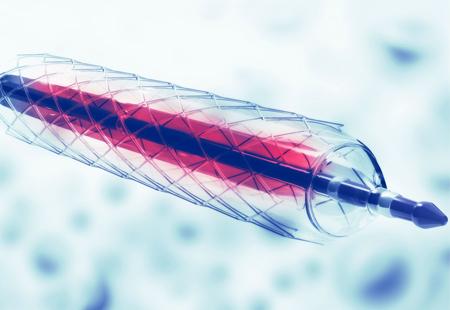

Very low extractables medical device adhesive withstands cleaning and sterilisation

Dymax 1045-M medical device adhesive was specifically formulated for the assembly of glass pre-fillable syringes, pen injectors, auto injectors, wearable injectors, and single-use devices. This very low extractables adhesive provides strong bonds that withstand the harsh cleaning and sterilisation processes pre-filled syringes undergo. Dymax 1045-M is also optimised to cure with LED UV light, providing […]

Read More

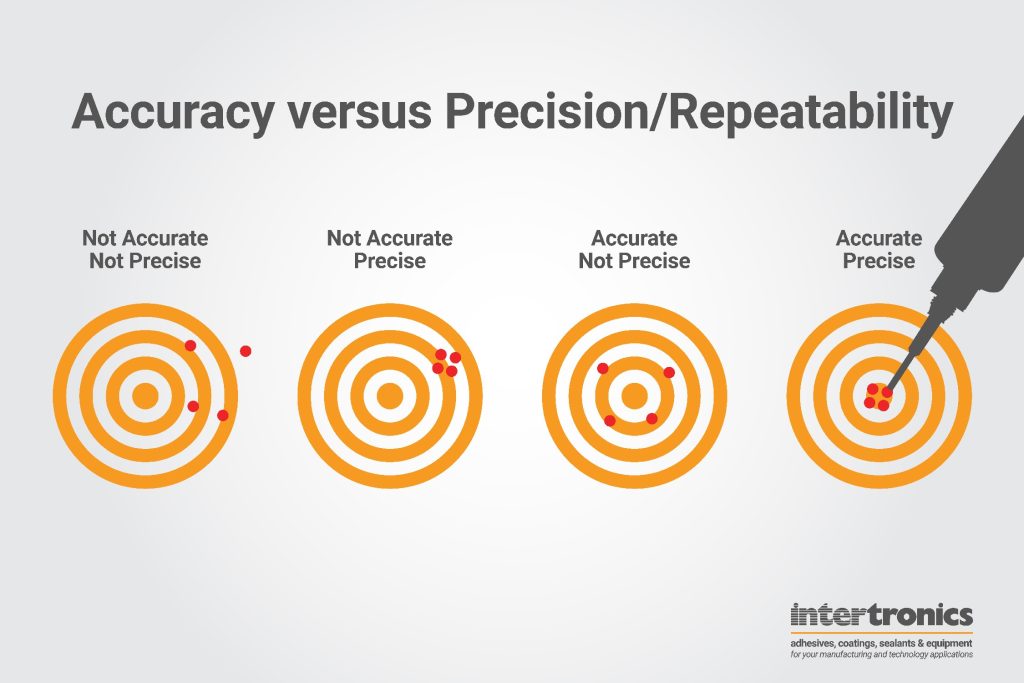

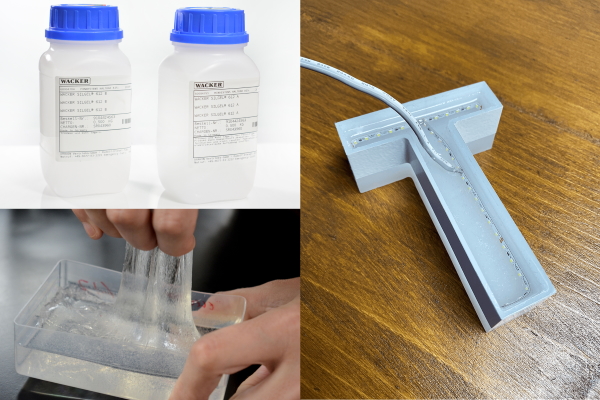

Accurate, repeatable mixers in scientific research

In the scientific community, particularly in universities, THINKY Mixers are becoming more prominent as a way to mix challenging liquids, pastes, and powders in research into nanotechnology, batteries, electronics, pharmaceuticals, and many more applications. A simple Google Patents search for “THINKY” demonstrates the huge number of technology and scientific breakthroughs that relied on the abilities […]

Read More

How big a dispensing robot do I need?

Robots are good for productivity, and if you’ve come to the conclusion that you can achieve a good return on investment through a robot purchase, you may find yourself wondering where to start with robot selection. We wrote a quick list of things to consider in our post How to specify a dispensing robot. Having […]

Read More

High temperature adhesive for metal bonding in automotive, rail and component manufacturing

SCIGRIP® SG800 High Temperature MMA Methyl Methacrylate Adhesive is a two component structural adhesive for bonding metals, as well as composites and plastics. Designed to withstand temperatures up to 150°C over prolonged periods, SCIGRIP SG800 is suitable for applications like under the bonnet engine bay component assembly and metal bonding prior to paint baking cycles. It displays good strength […]

Read More

Fluorescence in adhesives and coatings

I saw a newsletter article which said that fluorescent animals are much more common than previously thought. Researchers who studied 125 mammal species, including cats, bats, polar bears and wombats (pictured), found that all of them showed some form of fluorescence, and that 86% had fur which actually glowed under UV light. This picture is […]

Read More

Bonding specialist medical device plastics

Medical device manufacturers are increasingly turning to specialist plastics formulated to resist harsh chemicals and survive environmental end use conditions such as sterilisation. However, the properties that allow these materials to withstand such conditions can also make them difficult to bond with adhesives. Here Kevin Brownsill, our Head of Technical: Learning and Development, shares guidance […]

Read More

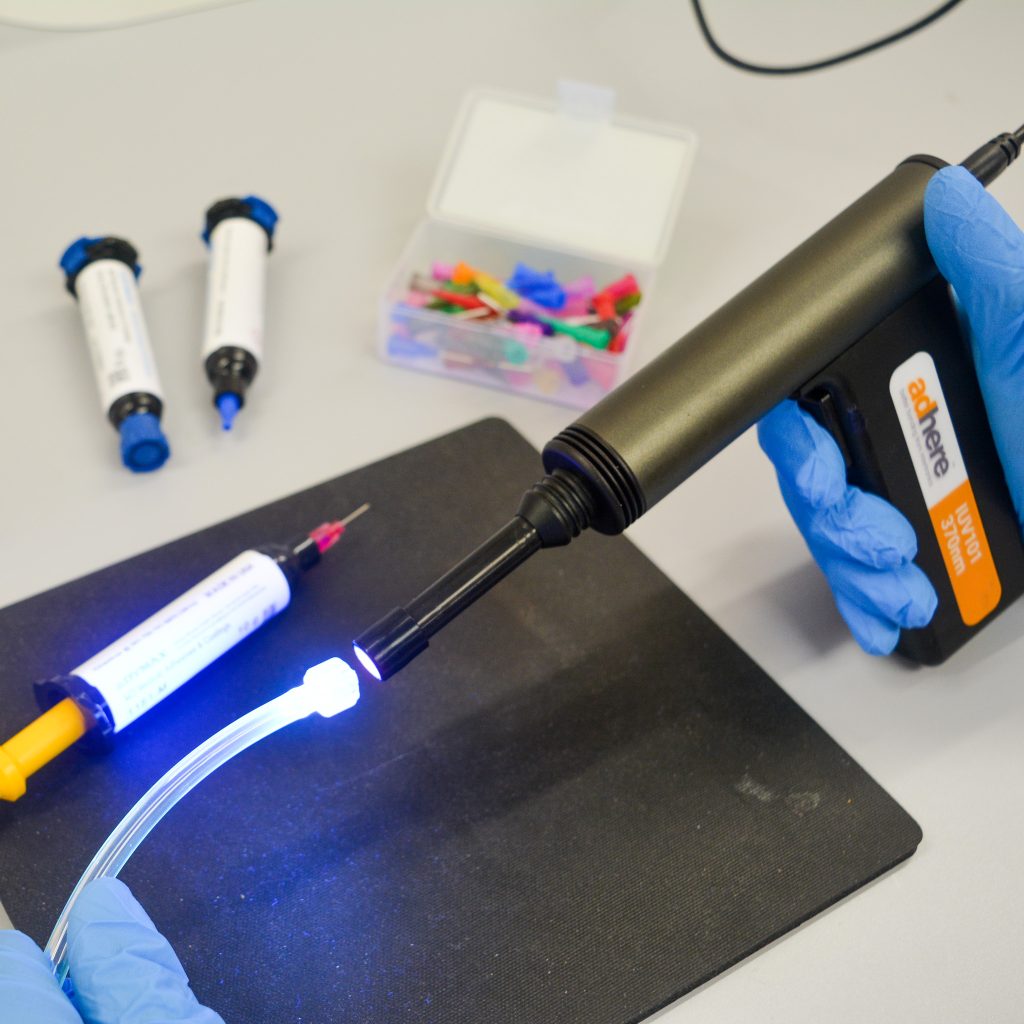

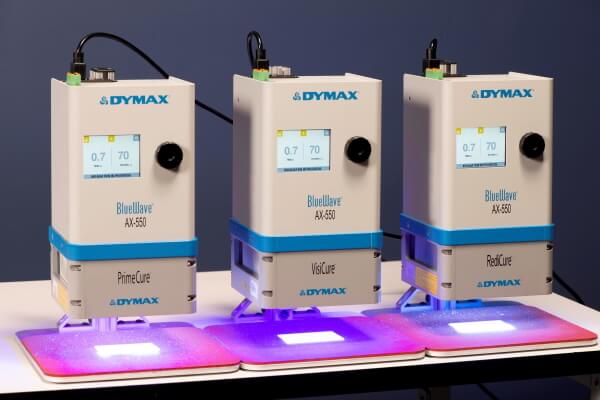

LED UV adhesive evaluation kit for medical device assembly

The IUV101 Medical Kit contains everything a manufacturer needs to start working with UV curing adhesive technology for medical device bonding, including three widely used adhesives in 10 ml syringes, alongside the IUV101 LED UV Spot Lamp for Handheld UV Light Curing. This device has a powerful 2,000 mW/cm2 light intensity, which users can focus on […]

Read More

Bringing Oxfordshire’s finest together

We have joined Oxfordshire-based business network, B4 as a PLATINUM Member. The move allows us to interface with senior business leaders in Oxfordshire, share expertise, advise on best practice, and discuss how to tackle the business challenges of the future. B4 actively connects the leading people from Oxfordshire-based business who value being part of a […]

Read More

Intertronics becomes UK distributor of Scigrip MMA adhesives

We’ve partnered with SCIGRIP to distribute its methyl methacrylate adhesives (MMAs) in the UK. MMAs are fast curing, two-part structural adhesives that cure on mix at room temperature to form resilient bonds. They are ideal for structural bonding of metals, plastics, and composites in industries like marine, transportation, rail, automotive, and many others. MMA technology […]

Read More

How will the new REACH diisocyanate regulations impact manufacturers using polyurethane adhesives?

Polyurethanes are polymers composed of organic units joined by urethane links. They are used to make rigid and flexible foams, and also used to make varnishes and coatings, adhesives, potting compounds, and fibres. Their most common application is in foams, which makes up around two thirds of all polyurethane use. Globally, 6% of polyurethane use […]

Read More

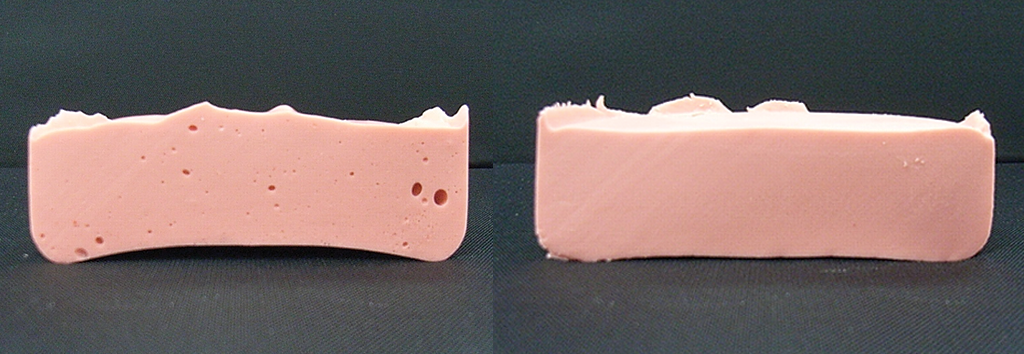

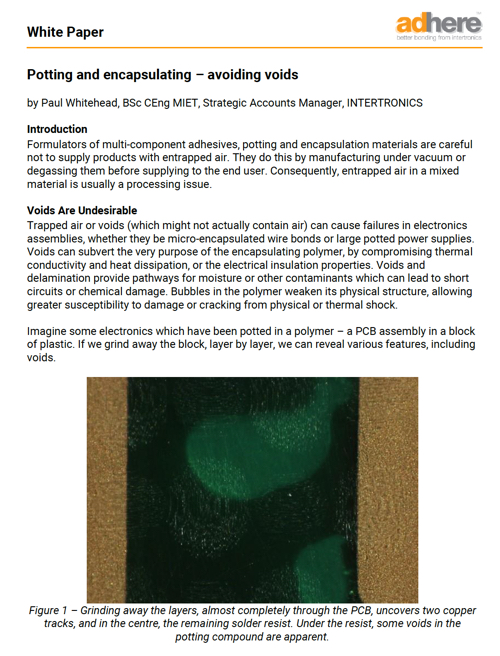

Avoiding voids in aerospace potting applications

Formulators of potting materials for aerospace electronics applications are careful not to supply products with entrapped air. Consequently, entrapped air is usually a processing issue which can compromise thermal conductivity and heat dissipation, or the electrical insulation properties. Voids and delamination can also provide pathways for moisture and other contaminates, weaking the physical structure. If […]

Read More

Preparation of advanced coatings on cathode materials using Thinky mixers

A shout out to Ed Harrison, a student at University of Birmingham. In the summer of 2022, the Faraday Undergraduate Summer Experience (FUSE) internship programme provided internships for undergraduate students to undertake paid eight-week placements with battery researchers from partner universities, and Ed was a part of this programme. His poster on Making and Testing […]

Read More

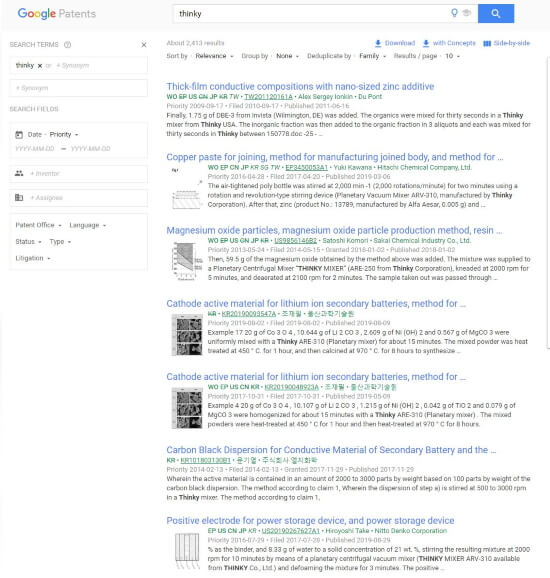

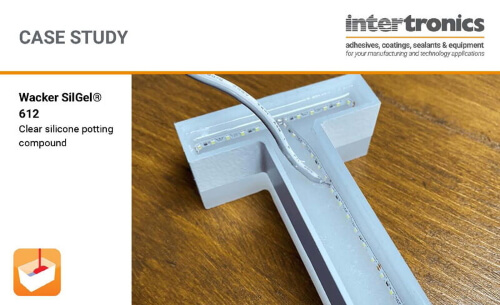

Case study: protecting rugged, outdoor work lights from the elements

Venta Global is a tier one supplier of lighting solutions to vehicle and machinery manufacturers, offering a complete service from custom design to delivery. It has made significant investment into new technology for its UK production facility in Hampshire that deskills processes to enable consistent and reliable results, removes inconsistencies due to operator variance, and […]

Read More

Award for Excellence ‘delivered’ to worthy colleagues

Big congratulations to James Heydon, Liam Rogerson, Joel Johnson and Grant Roche for picking up the Intertronics Award for Excellence at our recent bi-annual company meeting. Recognised for improving our packing and fulfilment process, the team made great strides in changing how we package, ship, and deliver your equipment and materials to your factory the very next […]

Read More

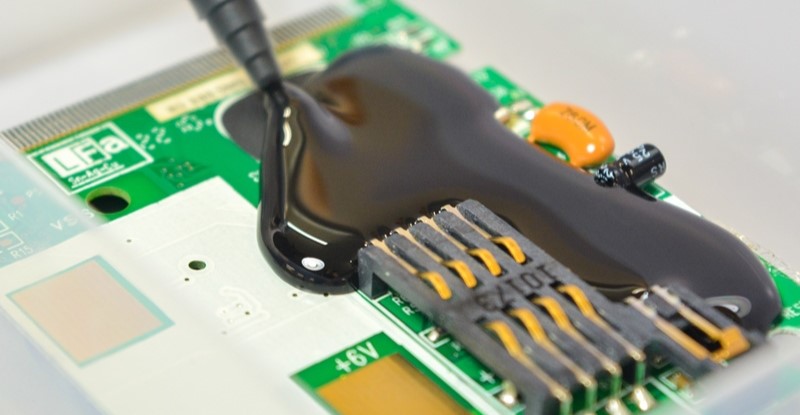

Three worked examples of potting PCB assemblies

Potting is a common method to protect PCB assemblies, which involves filling an enclosure with a liquid material to protect the board and its electrical components. Depending on your application’s needs, there are a wide range of potting compounds available in a variety of formulations, including low density/lightweight, flame retardant, flexible, optically clear, and thermally […]

Read More

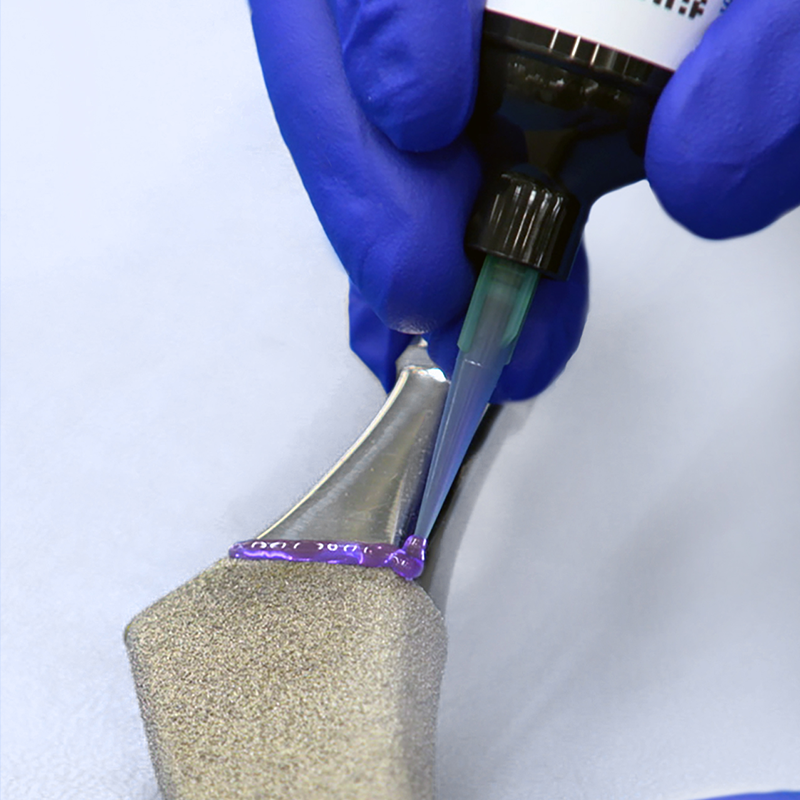

Masking orthopaedic implants effectively

Approximately 200,000 people receive hip or knee replacements in England and Wales every year, and these are typically highly effective. Research from the University of Bristol found that eight out of ten knee implants and six out of ten hip replacements last up to 25 years. To ensure long term success, orthopaedic implants must be […]

Read More

Point-One™ polyurethane adhesives do not require REACH training

The upcoming REACH training and certification requirements for users of diisocyanates are looming ever closer, impacting your use of many polyurethane adhesives in industrial applications. If you haven’t heard about this, read more here. Point-One Structural Polyurethane Adhesives are fast-curing two-part adhesives that form strong, durable bonds in as little as 10 minutes. They are […]

Read More

adhere academy: adhesive and dispensing technology seminars for you

Having spent more than 30 years working with adhesives and protective materials in technology manufacturing, and with experience of thousands of applications, we have a wealth of knowledge to we want to share. In a bid to help grow your adhesives, dispensing, and curing technology knowledge, we are offering seminars which share our insights, helping […]

Read More

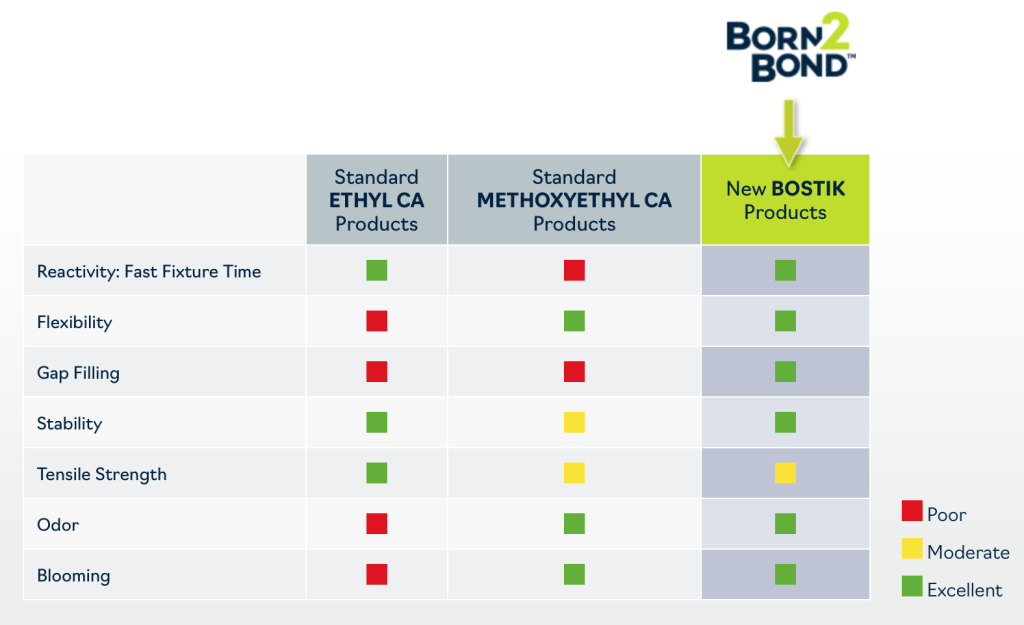

Best cyanoacrylate adhesive for structural bonding

Cyanoacrylate adhesives (CAs) have not traditionally been seen as structural adhesives or “load-bearing” adhesives – in general, their lower performance in terms of moisture and operating temperature resistance will preclude them from many technology applications. But advances in chemistry are improving the functionality and so the versatility of CAs. If you’re seeking an adhesive for […]

Read More

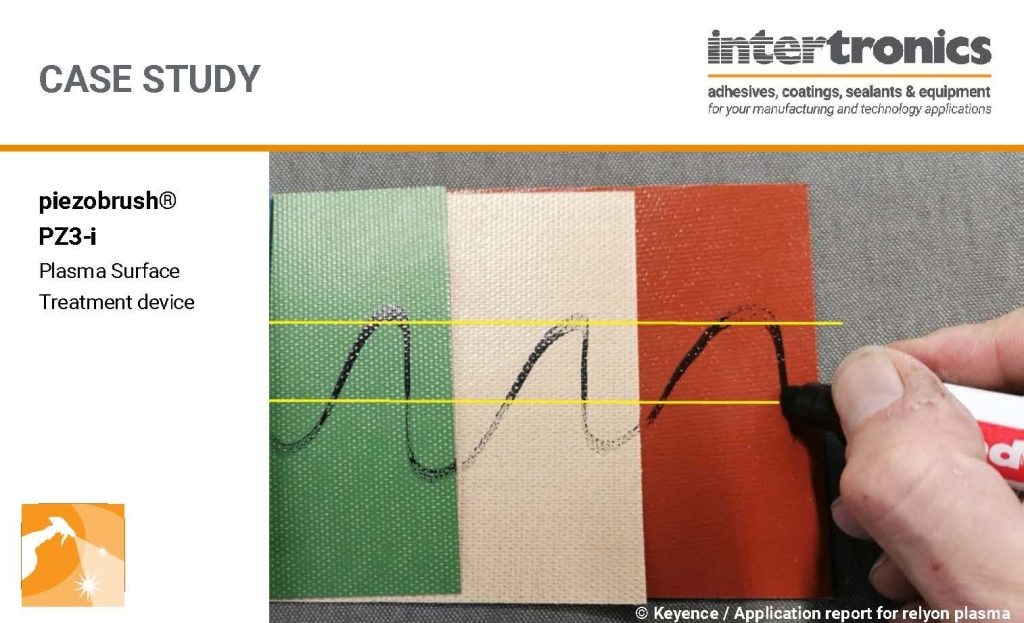

Case study: achieving reliable printing onto PTFE with plasma pre-treatment

Due to PTFE’s extremely low surface energy, it is difficult for materials to wet, and almost no materials or adhesives readily adhere to it. The commonly known brand name of PTFE-based composition is Teflon – yes, the non-stick stuff. However, plasma can be applied to alter the chemical groups on the surface, increase wettability and […]

Read More

Dispensing robots: what’s the risk?

Robots: the opportunities… or the risks? The application of adhesives, potting compounds, encapsulants or other liquids, fluids or pastes, is something that can often be readily automated with a dispensing robot. Manufacturers that are still performing these processes manually may be concerned about the potential risks of transforming their processes with automation. On the other […]

Read More

New legislation on the use of polyurethane adhesives and potting compounds

As of 24 August 2023, training is required for all professional and industrial users of polyurethane adhesives & sealant products with a total monomeric diisocyanate concentration of > 0.1%. New legislation on the use of polyurethane adhesives and potting compounds Following a review by the European Parliament, the REACH Restriction on aliphatic and aromatic diisocyanates (HDI, MDI, […]

Read More

Busting 10 misconceptions about robotic dispensing

The benefits of robotics are compelling to many manufacturers: improved productivity, efficiency, output, quality, and flexibility. They can also improve health and safety for employees and job satisfaction. The International Federation of Robotics World Robot Report in 2021 found that the UK has a robot density of 101 robots per 10,000 employees, far below the […]

Read More

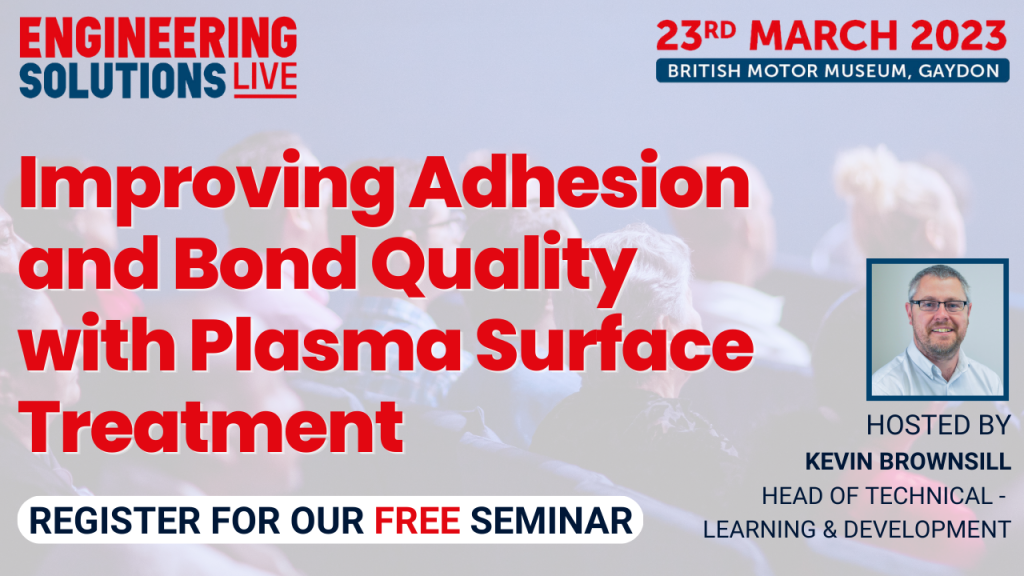

Seminar: Improving Adhesion and Bond Quality with Plasma Surface Treatment

We’re delivering a free seminar at the upcoming Engineering Solutions Live show, held on the 23rd of March, entitled Improving Adhesion and Bond Quality with Plasma Surface Treatment. Cold plasma treatment can quickly activate and functionalise the surfaces of many difficult-to-bond substrates, including metals and plastics, whilst removing organic contaminants. This process improves the wetting […]

Read More

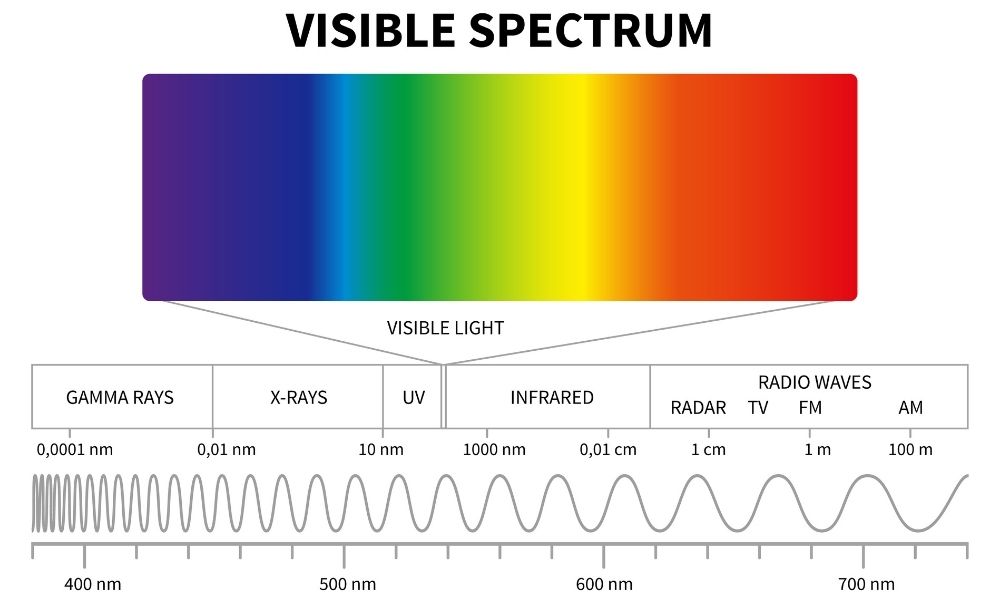

adhere academy: can you see UV light?

UV or ultraviolet light is part of the spectrum of electromagnetic radiation, which also includes radio waves, microwaves, infrared radiation, X-rays, gamma rays – and of course, visible light. These different types of radiation are defined by their wavelengths or frequencies. Radio waves have the longest wavelengths, and gamma rays the shortest. By definition, what […]

Read More

Moisture-resistant cyanoacrylate adhesive increases application potential

Cyanoacrylate adhesives (CAs) are often dismissed when it comes to applications with moisture exposure, let alone involve full submersion. That was until our partners, Born2Bond, developed a new single-part, “instant” adhesive specifically suited for environments with high humidity. Born2Bond Aquafast is a low odour, low bloom, medium-viscosity CA that offers excellent adhesion to a variety […]

Read More

Kevin Brownsill promotes knowledge of adhesives technology to UK manufacturers

Kevin’s been at Intertronics for 15 years, having started in Sales and progressed into Sales and Technical management. Over this time, he’s developed a deep understanding of this specialised area, as well as built strong relationships with customers, and has taken responsibility for our Technology Centre. To help grow understanding of the selection and processing […]

Read More

Engluesiasm – the cure for flatlining

Today we learned that the UK economy has escaped recession, albeit by the skin of its teeth, and… so far. I heard on the radio that the economy is “flatlining”, which has disturbing connotations if you are a cardiac surgeon, but just means here that the growth curve not going up or down. I visited […]

Read More

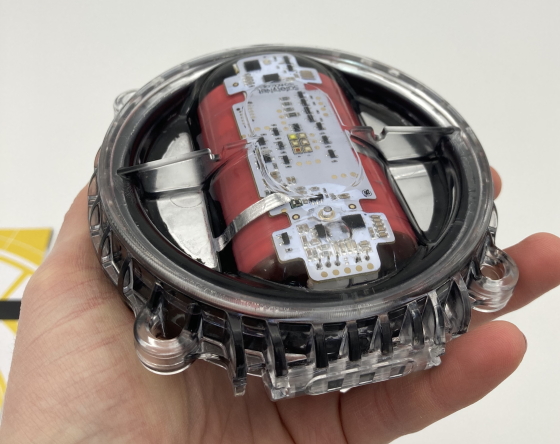

Case study: potting a bespoke telematics system

Bulk Tainer Logistics provides bespoke transport services for the shipment of bulk liquid products globally, operating a fleet of 12,000 chemical, feed, and food grade tank containers. To optimise the performance of its fleet, the company wanted to fit its tanks with smart monitoring devices that tracked the movement of the tanks and the condition […]

Read More

RFID tracking on surgical instruments

British surgeons are getting rather slapdash, according to The Knowledge. The number of “foreign objects” left inside patients after operations hit a record 291 in the year from 2021 to 2022, up from 156 two decades earlier. Swabs and gauzes are the most common items sewn up in patients, but scalpels and drill bits have […]

Read More

Christmas greetings, holidays and our community

We wish you a Delightful Christmas, and a Healthy, Peaceful and Prosperous New Year. Thank you for working with us during 2022. We are closed at 5pm on Thursday December 22 2022, and reopen again at 9am Tuesday January 3 2023 Each year we try and support some charity, especially ones which have some resonances […]

Read More

Putting food on local tables

It has become a Christmas tradition at Intertronics for us to collect donations for the North Oxfordshire Community Foodbank, a local source of support for people struggling to put food on their tables. Our team members came good with a cornucopia of larder staples and treats, and we also accepted kind donations from people visiting […]

Read More

Achieving meaningful ROI with robotics

The benefits of robotics are compelling; improved productivity, efficiency, output, quality, and flexibility. In addition to their production benefits, they can also improve health and safety and job satisfaction for employees. However, the International Federation of Robotics (IFR) World Robot Report in 2021 found that the UK has a robot density of 101 robots per […]

Read More

Best cyanoacrylate adhesive for wood, leather, cork or paper

Cyanoacrylate adhesives (CAs) contain an acidic inhibitor which prevents them from curing in the bottle, instead allowing the adhesive to cure upon exposure to low-level surface moisture or alkalinity (see our Adhesive Problem? What’s the Cure? download for more information). With acidic substrates, this cure mechanism can be compromised. If you are working with a […]

Read More

Case study: SpeedMask – application time reduced from 4 hours to 14 minutes

The masking process at MTU Aero Engines, a leading German manufacturer of military and civil aircraft engines, used to involve tapes, silicone rings, masks and metal covers all manually fitted and applied by operators. So when production planner Thomas Kaltenecker discovered and implemented Dymax SpeedMask, a UV-curing temporary masking liquid, alongside an automated dispensing and […]

Read More

Let’s get started by talking about your application

Let’s get started by talking about your application. This is a phrase you’ll see a lot around here, and it sums up our whole approach. We consider ourselves to be your adhesive-savvy team members, and we want to get stuck in to helping you create a product that you’re proud of, both in terms of […]

Read More

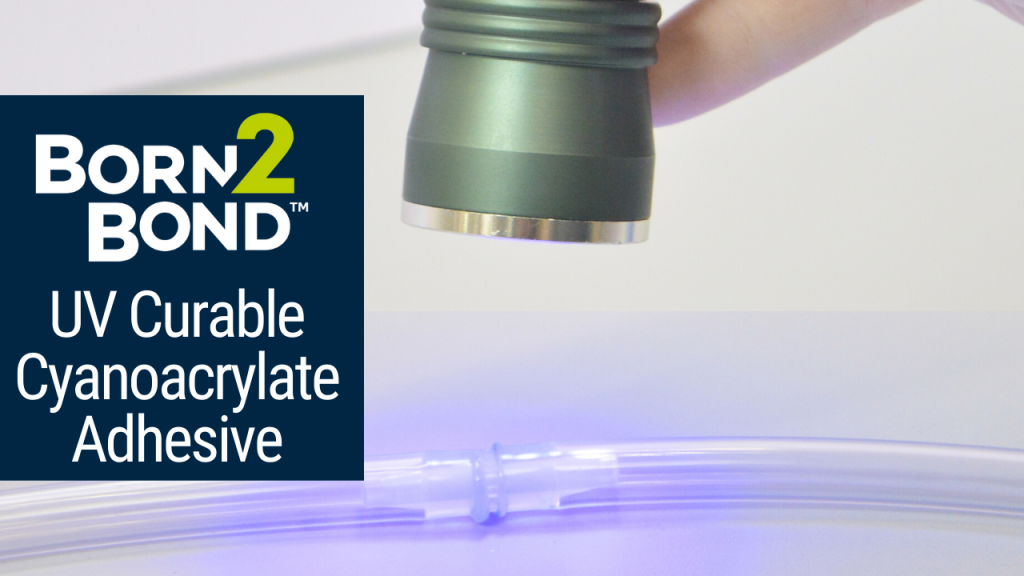

Best cyanoacrylate adhesive for shallow potting, encapsulation and bridge bonding

In applications where the adhesive is at least partly exposed (not completely interfacial), Born2Bond LightLock is worth evaluating. It is a hybrid cyanoacrylate adhesive that reacts to UV light to cure, making it a solid choice for bondline squeeze-out, electronics encapsulation or shallow potting, and bridge bonding applications like wire tacking. LightLock doesn’t require activators […]

Read More

UV curing intensity – check your distance

A fundamental element of achieving the correct dose of UV light is ensuring the intensity of your UV curing lamp is understood. UV curing intensity as noted on a lamp’s data sheet is typically measured from a particular distance, so if your lamp is not set up to the same distance as the data sheet […]

Read More

We’re JOSCAR accredited

We are pleased to be accredited and on the JOSCAR supplier register, offering our customers in the aerospace, defence and security industries the confidence of knowing that we meet their high standards of supplier conformance. Using JOSCAR can determine if a supplier is “fit for business”. JOSCAR (Joint Supply Chain Accreditation Registrar) is a collaborative […]

Read More

Best cyanoacrylate adhesive for moist environments

Cyanoacrylate adhesives typically perform poorly in high humidity or wet conditions, but there are exceptions to this rule. If your finished product will be exposed to a moist environment, we recommend trying Born2Bond Aquafast cyanoacrylate adhesive. It offers the standard benefits of cyanoacrylates – quick cure speed, adhesion to a broad variety of substrates, and […]

Read More

Aiding first aiders, helping a colleague

When our colleague Darren‘s first aid course for volunteer rugby coaches found itself without a venue, Intertronics stepped in to provide space. We hosted a group of eight volunteer coaches, including Darren, from the Youth, Women, and Girls sections of the Gosford All Blacks Rugby Football Club. Gosford All Blacks are a local community club […]

Read More

25 top tips for optimally dispensing your materials

If your process involves dispensing materials like adhesives, inks, coatings, sealants, lacquers, paint, lubricants, or anything similar, our 25 Top Tips for Dispensing is worth a read – a collection of handy tips covering many dispensing applications which can help you fine-tune what you’re doing for optimal results. Covering dispensing pressures to types of dispensing […]

Read More

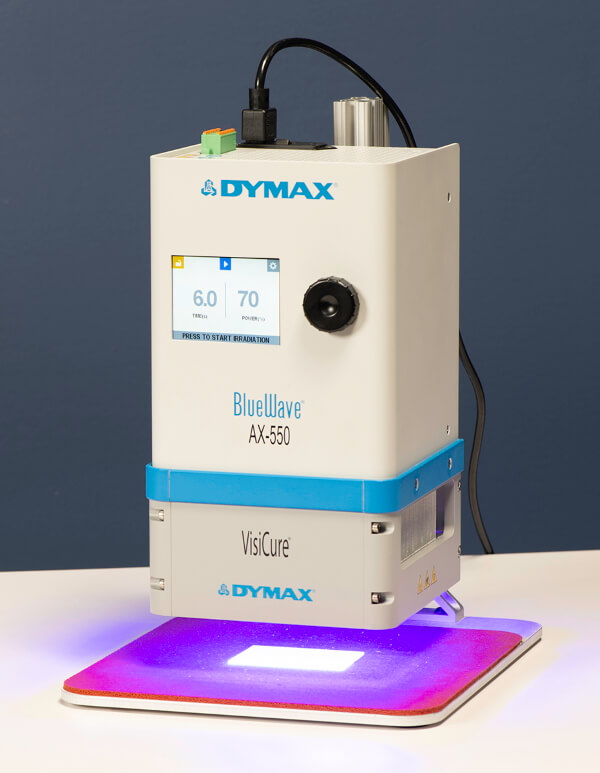

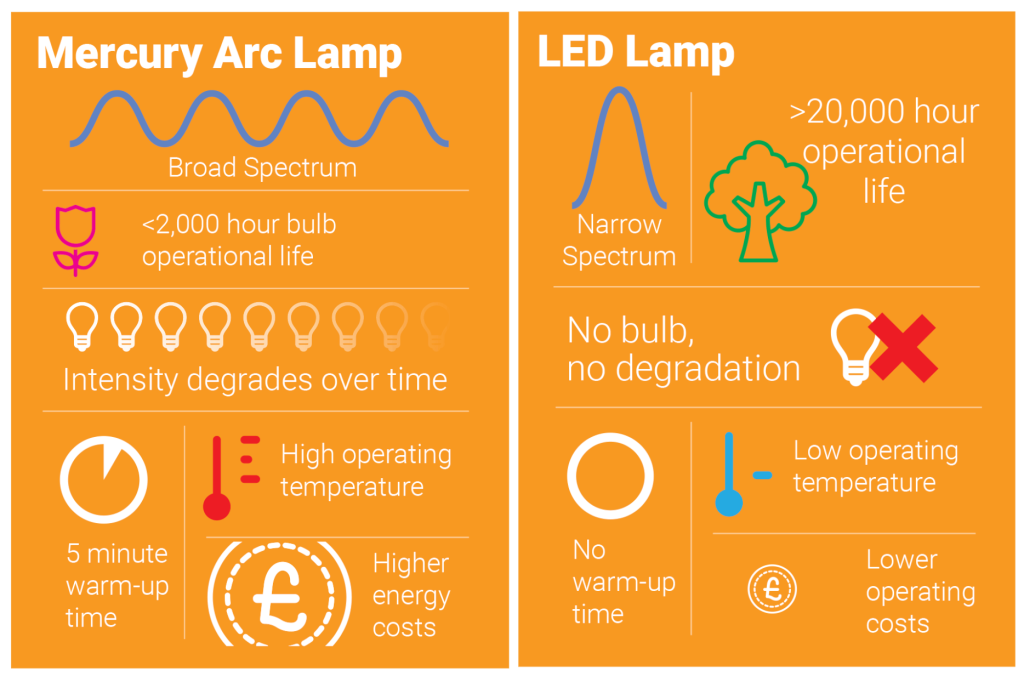

White Paper: Sustainability benefits of LED UV curing

LED UV curing lamps are swiftly gaining popularity as a replacement for mercury arc lamps. Their rise in use reflects their process benefits, such as instant on/off and consistent intensity for thousands of hours. In addition to these, there are environmental advantages at play, such as reduced energy consumption, decreasing a business’ carbon footprint, and […]

Read More

Electronics Industry Awards – we are finalists

A bit of excitement around here as we have been listed as finalists in the Medical Product of the Year category at the 2022 Electronics Industry Awards. We have been recognised for releasing Dymax’ 2000-MW series of medical device materials – a range of medical wearable adhesives and encapsulants which help adapt wearables devices to […]

Read More

Best cyanoacrylate adhesive for gap filling

Cyanoacrylate adhesives (CAs) are renown for being thin, watery liquids. That is their nature. This doesn’t help when your bondline is wider than ideal, or varies into larger gaps. In these cases, you will want a CA which has an unusually higher, thicker viscosity – and these do exist. CAs are now available in a […]

Read More

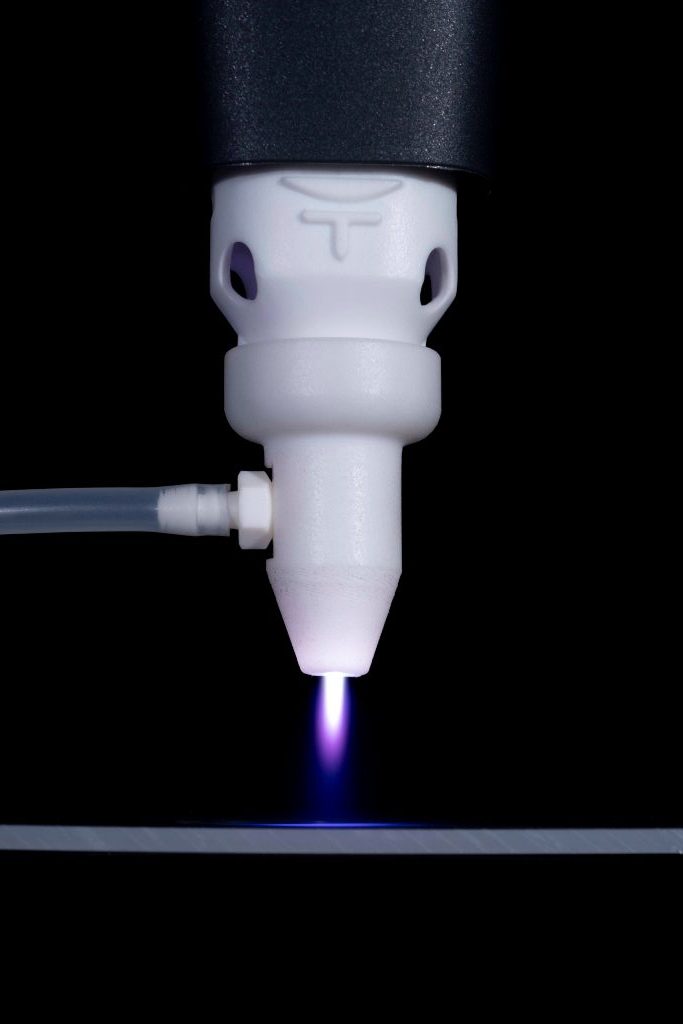

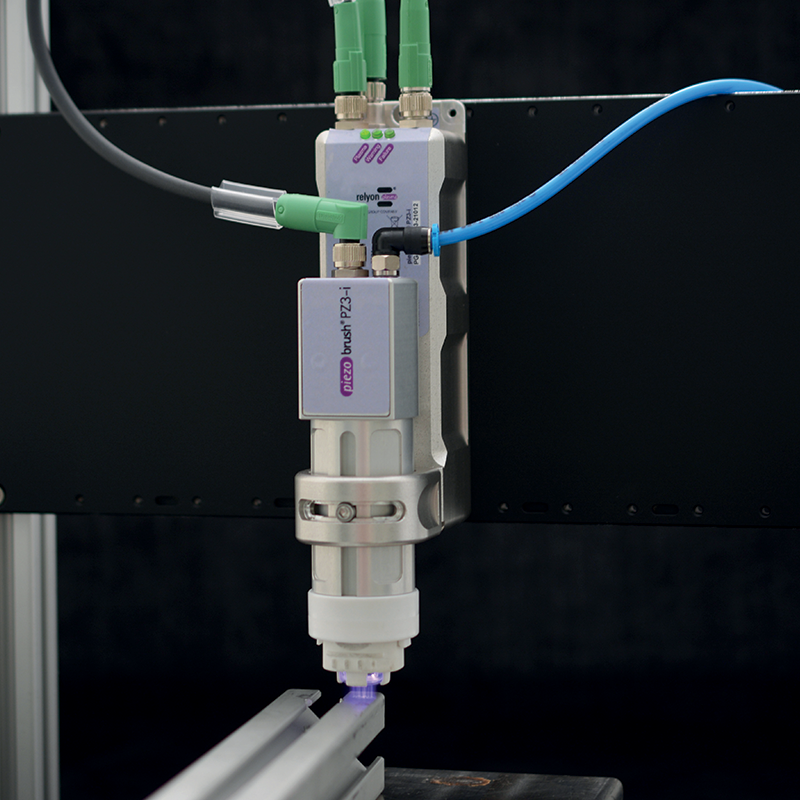

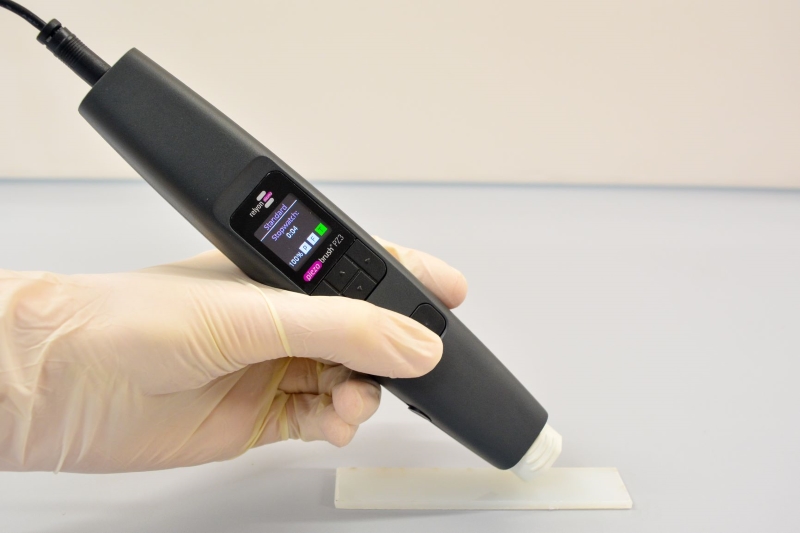

New plasma surface treatment module attachments expand applications

The most hard-to-bond substrates and awkward areas are now treatable with low temperature, plasma surface treatment. Two new modules, released by Relyon Plasma for their popular PiezoBrush PZ3 and PiezoBrush PZ3-i plasma systems, expand the applications which can benefit from activating, functionalising, and cleaning to increase wetting and improve adhesion. Needle Nozzle Cleaning and […]

Read More

Best cyanoacrylate adhesive for medical device assembly

For a medical device assembly adhesive which also provides the benefits of cyanoacrylate adhesive technology (e.g. single part, fast cure), we recommend you look at Born2Bond Light Lock. Light Lock passes ISO 10993 testing and is also a UV hybrid cyanoacrylate. The UV light curing aspect of Light Lock is useful for a bondline which […]

Read More

Case study: improving overmoulding adhesion with plasma treatment

Founded in 2020, Wavecon specialises in cable solutions for subsea assemblies, offering a range of options from the supply of replacement cable harnesses and wired assemblies, through to fully designed and manufactured bespoke assemblies for specific applications. From the outset, the company decided to build an end-to-end manufacturing process, using high quality equipment, machinery and […]

Read More

White Paper: Adhesive considerations at the design stage

When it comes to the design and development of new products, and choosing an adhesive to bond them together, an adhesive supplier often finds themselves as the last port of call. This approach can leave you in a position where your list of requirements severely limits the adhesives suitable for your application. Bondline design, substrate […]

Read More

Best cyanoacrylate adhesive for high temperatures

The majority of cyanoacrylate adhesives (CAs) have an operating temperature range up to 80ºC. If your application needs more temperature resistance, and you like the other advantages that CAs can offer, then adhere ADH9105 and adhere ADH9480 rubber-toughened cyanoacrylate adhesives both offer temperature resistance up to 125ºC, making them our most temperature-resistant CAs. Coming in […]

Read More

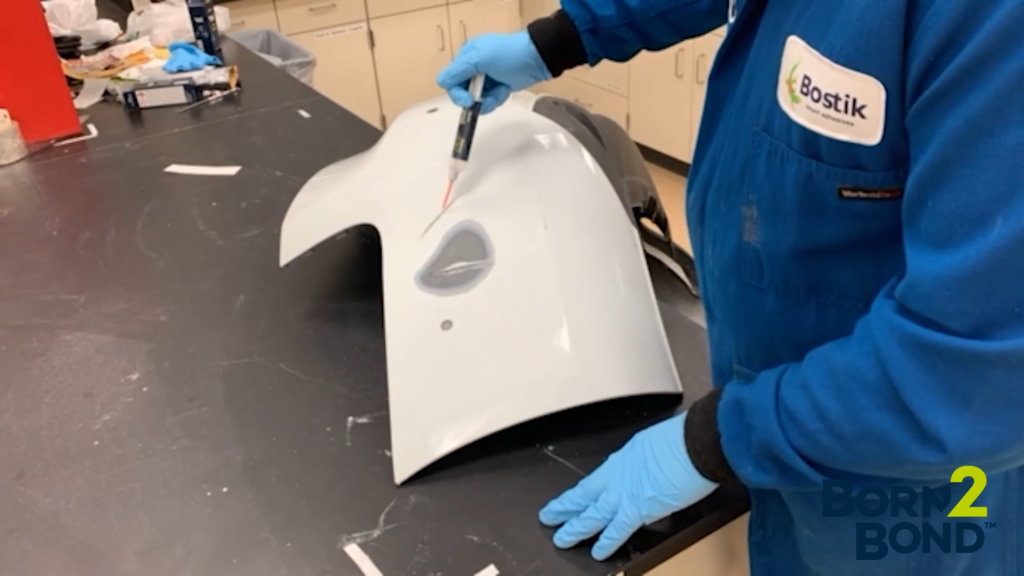

Article: New applications for light curable adhesives in medtech

The latest issue of Med-Tech Innovation News is out, and we are delighted to have an article published in it. Seeing the light: New applications for light curable adhesives in medtech discusses some of the latest formulations of UV curing adhesives used for assembling wearable medical devices, as well as some ideas on adhesives which […]

Read More

Dispelling 10 popular myths about cyanoacrylate adhesives

Cyanoacrylate adhesives (CAs) — also known as “superglue” or instant adhesives — are a popular adhesive choice for many applications, both industrially and domestically. Curing at room temperature in seconds, they provide excellent bond strength on a wide range of similar and dissimilar substrates including metals, plastics, elastomers, ceramics, and porous materials. Achieving these throughput […]

Read More

Dispensing automation: an ROI story

“I am the Managing Director of an electronics CEM. We are making 1,000 potted electronics assemblies per week, regularly 200 per day. This is done manually by experienced operators. Pat is my best operator, she’s been with me the longest time. Some weeks, about 2.5% of these are rejected after potting. Each one costs £50, […]

Read More

Improved metal bonding performance with Born2Bond Ultra CA

Our partners at Born2Bond have been busy improving the functionality and sustainability of their cyanoacrylate adhesives (CAs). As a result, Born2BondTM Ultra, the fastest-bonding MECA-based CA, now has “significantly improved” performance when used to bond metal substrates such as grit-blasted mild steel (GBMS) and aluminium. The metal bonding improvements can be seen across all viscosities […]

Read More

Case study: improving mixing accuracy and repeatability for 3D printed bioelectronics research

To improve the way recovery from injury and the progression of neurological/musculoskeletal conditions are monitored, the Department of Automatic Control and Systems Engineering (ACSE) team at the University of Sheffield is developing a diagnostic glove that includes several flexible bioelectronic sensors. The sensors are formed from elastomers mixed with various conductive nano or micro particle […]

Read More

Getting started with UV curing is easier than you think

Attaining the near instant, ‘on demand’ bonding performance of UV adhesives and curing is now even easier with our IUV101 Starter Kit. Incorporating our popular IUV101 handheld LED UV spot curing lamp and three compatible multi-purpose LED UV curing adhesives in 10g syringes, you’ll be able to tackle a multitude of bonding projects as soon […]

Read More

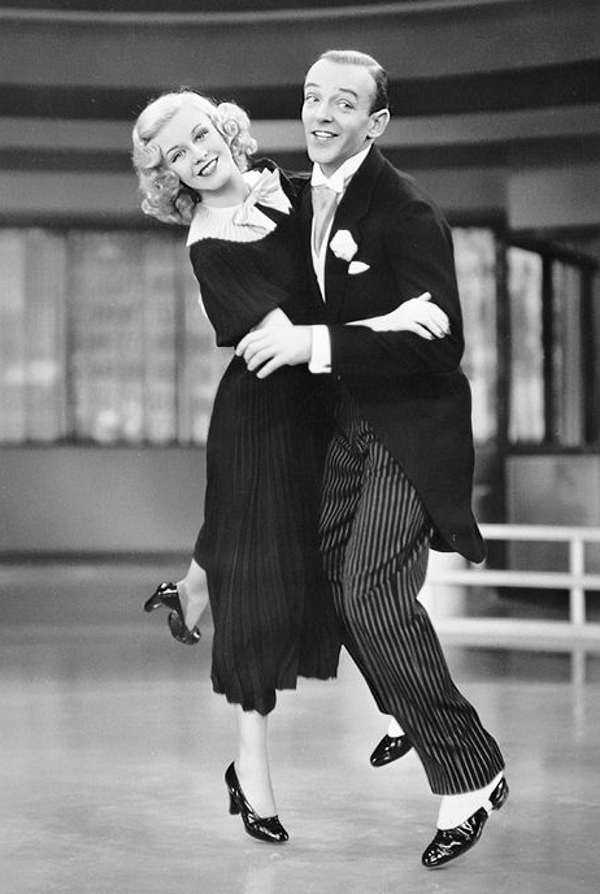

Partnerships – an illustration

Do you know who this couple is? For years I have been using this picture to illustrate one of our presentations. It gets used all the time, and is shown in job interviews, to new colleagues, prospective suppliers, clients, customers, and anyone else we introduce the company to. The slide comes up when I talk […]

Read More

Charity rugby session converts local school pupils to sport – Darren’s story

Being a fan of rugby for as long as I can remember, when the opportunity arose four years ago to coach the under 7’s team at my local rugby club, the Gosford All Blacks, I thought I’d give it ago. Since then, I’ve gone on to lead their schools and communities outreach programme which aims […]

Read More

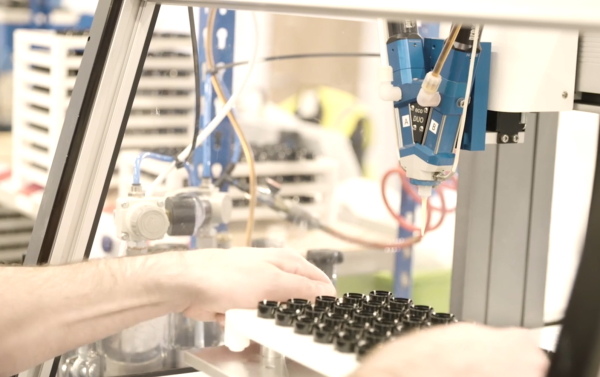

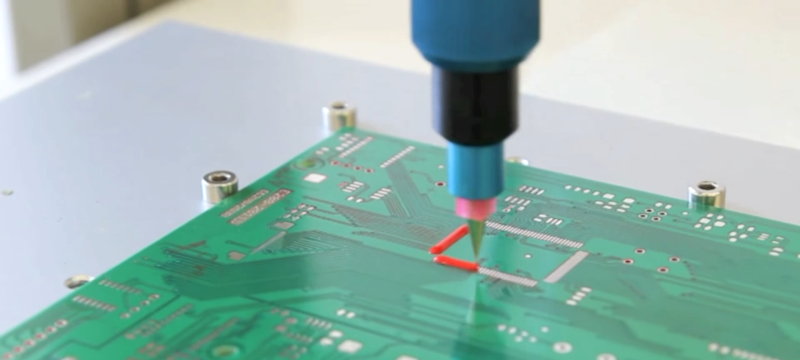

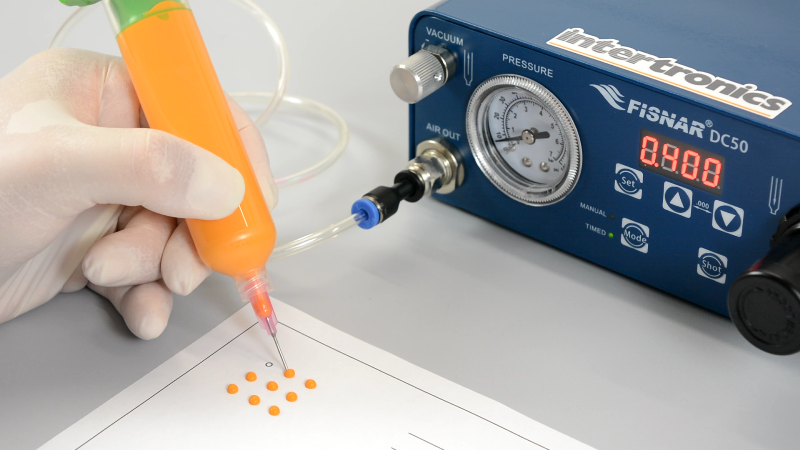

Case study: jet dispensing doubles productivity of water testing kits

To improve the accuracy, repeatability, and manufacturing speed of their key product line Kemio™, a water testing system utilising patented single-use sensor technology, Palintest came to us. Using electrochemical sensors, the product tests the concentration of chlorine, chlorine dioxide, chlorite or peracetic acid in samples, giving a clear pass or fail mark in 60 seconds. Initially […]

Read More

Getting charged up about our electric cars, and yours!

We’re always finding new ways to minimise our environmental impact as a company, from biodegradable packaging, to paperless transactions, to eliminating single-use cups from our water coolers. Our company fleet has been steadily modernising to electric vehicles. To support this, and to encourage employees who may be considering the purchase of their own electric car, […]

Read More

Plasma surface treatment – simple to automate

Providing you with an easy and affordable way to automate plasma surface treatment, the Relyon Plasma PiezoBrush PZ3-i allows simple integration into semi-automated or automated production lines whilst giving you full control over all process variables ─ positioning, power, time, and input gas pressure ─ for a repeatable, controllable, and recordable process. The PiezoBrush PZ3-i is […]

Read More

We are engluesiastic!

We are engluesiastic! I don’t have a written, precise definition for what that means, but I know it when I see it. It is often demonstrated by commitment to and promotion of our values. Here is a great example, a recent quote from a customer about our Strategic Accounts Manager, Paul Whitehead: “Intertronics were […]

Read More

Matt the Builder, Can He Fix It?

A perk of working at Intertronics is a paid day off each year to volunteer for a good cause. As a man who likes to get stuck in to practical, hands-on work, Matt Baseley used his volunteer day this year to get lots of odd jobs accomplished at his children’s nursery. The nursery is a […]

Read More

Stories from our customers – a case history collection

“The ability to mask complex shapes in one application and cure quickly on demand has reduced work in progress, improved quality and increased throughput.” “We have managed to increase production four-fold and enjoyed faster manufacturing time, reduced labour costs, and a consistently high-quality result with no defects or wasted material.” “It has allowed us to […]

Read More

Industry-first adhesives for skin contact wearables

The Dymax 2000-MW series is a range of medical wearable adhesives and encapsulants which help adapt your wearables devices to industry trends and customer requirements. These materials are the first biocompatible, light-curable adhesive product line to be specifically formulated without common skin irritants and materials of concern for medical wearable and electronics applications. All adhesives […]

Read More

How do you dispense thermal adhesives and pastes?

Thermally conductive materials are often used to enhance the dissipation of heat from an electronic device. They are used to fill the gaps between two or more elements, such as a microprocessor and heat sink, or a battery cell and its casing in electric vehicles. As well as aiding the transfer of heat, some thermally […]

Read More

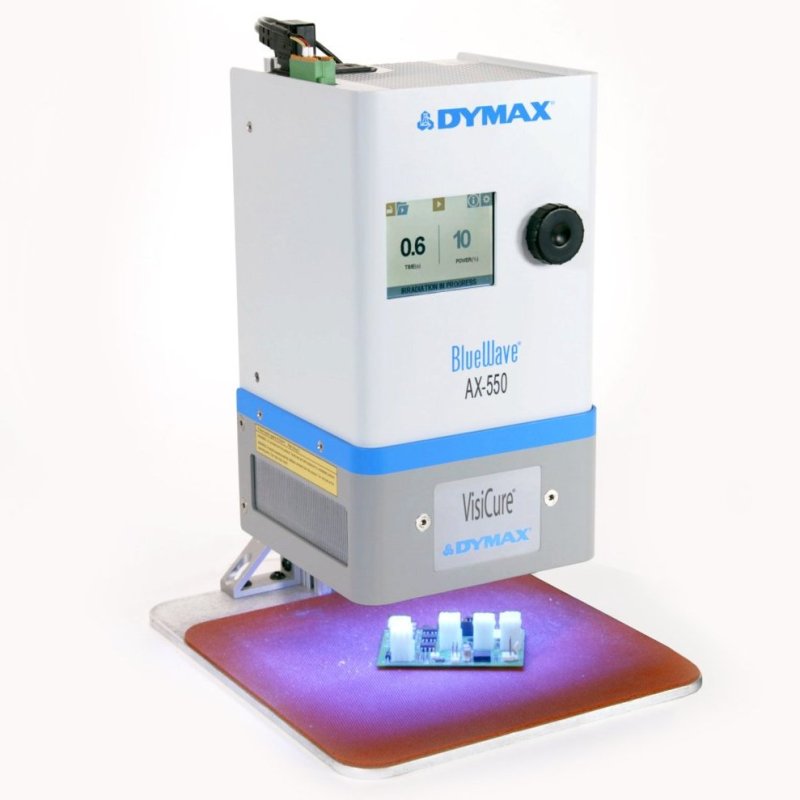

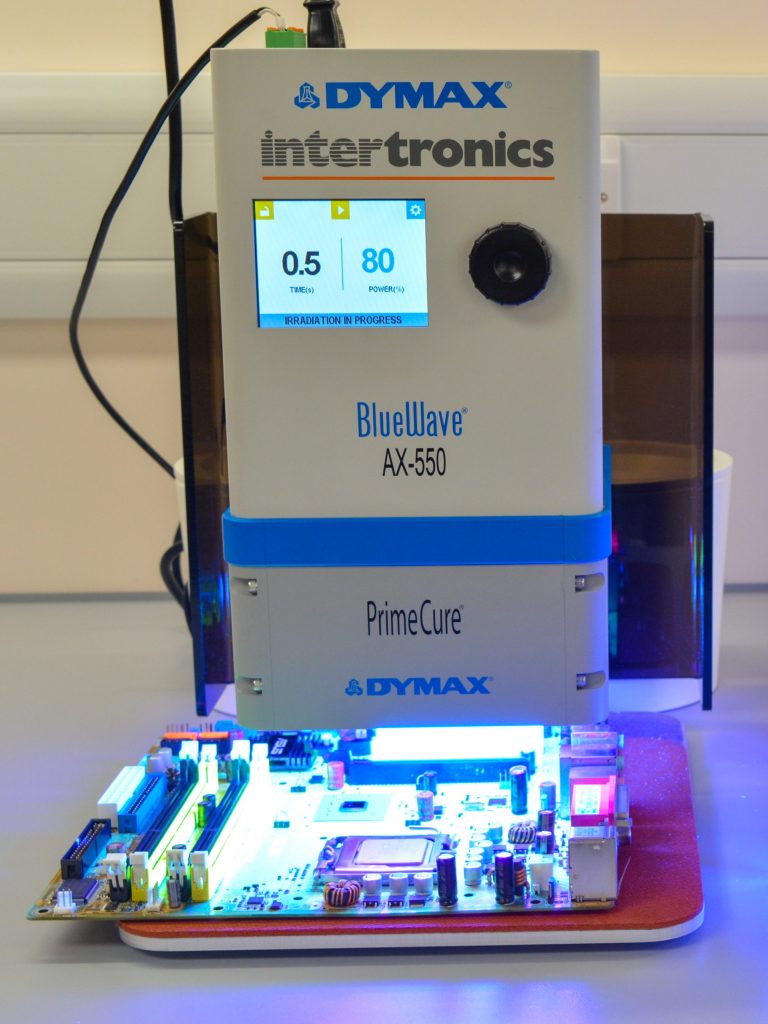

Flood your components with high intensity LED UV light

To help you boost production speed, consistency, and reliability with LED UV curing, we’ve introduced the Dymax BlueWave® FX-1250 LED UV Curing Flood Lamp. The lamp can cure LED matched UV curable adhesives, coatings, and inks in seconds with high uniformity, high irradiance UV light. The combination of great uniformity, high intensity, and large curing […]

Read More

Atlantic Escapade

We are very clear in our belief that contributing to our community helps to provide meaning and significance to our business, and we are always looking for and happy to hear about opportunities to do just this. As we are pretty far from the ocean, what we didn’t expect to be able to help with […]

Read More

Adhesive for electric vehicle battery potting and bonding

Dymax Ultra Light-Weld® 9501-F is a UV/Visible light-curing adhesive optimized for LED curing at 385nm designed for electric vehicle battery potting and bonding. This material provides a highly reliable bond for cylindrical cells to the base of the battery pack. This colourless adhesive contains no nonreactive solvents and will fluoresce blue upon exposure to low […]

Read More

White Paper: Designing in light curing adhesives – a holistic approach to adhesives in medical device assembly

UV curable adhesives grant significant manufacturing productivity benefits, curing in seconds, “on-demand” when exposed to UV light. With grades certified to ISO 10993 and USP Class VI stands available, they are also well-matched to the manufacture of medical devices. To fully realise the potential that this adhesive technology can bring, it is necessary to take […]

Read More

Get hands-on with trials and demos for adhesives and equipment

For years, we have helped our customers develop their production through evaluation and specification of new assembly materials and equipment at our Technology Centre, located in Kidlington, Oxfordshire. Filled to the brim with mixing, surface treatment, dispensing, robots and curing equipment, along with a warehouse full of materials, our Centre allows us to help you […]

Read More

Remote control of preeflow dispensing programmes

For automated or semi-automated applications involving preeflow’s range of precision volumetric dosing valves, which require the use of several different pre-programmed flow rates or shot sizes (or both), the preeflow eco-REMOTE can be used. The eco-REMOTE is an interface between the preeflow eco-CONTROL control system and an external controller (e.g. a PLC). It allows the activation of […]

Read More

adhere academy: what does hygroscopic mean?

Hygroscopic materials attract and absorb humidity from the air. An example is the way granulated sugar gets lumpy in the sugar bowl or salt clumps in the salt shaker blocking the holes when in humid environments like a steamy kitchen. Lots of materials are hygroscopic, including paper, isopropyl alcohol (IPA), and plastics like ABS. Nylon […]

Read More

Adhesive selection: A race against the clock?

There are a few considerations when specifying an adhesive for your application, such as how well it bonds your substrates and if it can meet the functional needs of your application. One other important piece of the puzzle are the time-based factors which dictate how materials can be processed. Our technical white paper Adhesive selection: a race against the clock? walks you through the various time-sensitive factors at […]

Read More

Case study: epoxy mixed by THINKY headed to the Moon

It’s been 50 years since the USA softly landed a spacecraft on the Moon’s surface. Something Intuitive Machines, based in Texas, is looking to change. When sending expensive, often delicate, machinery and equipment into the depths of space, achieving the most reliable bonds between components is mission critical. For this very reason, Arnab Roy, Production […]

Read More

Case study: a clear potting process for a sustainable fishing device

To aid the rapid development of a new deep-sea fishing device, sustainable fishing start-up SafetyNet Technologies (SNTech) reached out to us. In a close collaboration, SNTech specified two materials, Opti-tec™ 4210 and IRS 3071, and developed a reliable assembly process. The new device, Pisces Deep, has since passed pressure tests at 100 bar and is […]

Read More

Meet the Intertronics team!

Our team has been providing technical support, advice, and expertise since Intertronics began, some 40 years ago. We have been diligent in quickly answering your questions about prices, delivery, process enhancement, health and safety, and the upkeep of equipment you have bought from us years ago. During that time, you may have met some of […]

Read More

Supporting our local food bank, Christmas 2021

2.5 million. That’s the staggering number of food parcels handed out in the 12 months to April 2021 by the UK’s largest food bank charity. With a record number of households set to utilise these vital services over the festive break, the team at Intertronics are keen to play our part in supporting our local […]

Read More

Christmas Greetings, Holidays, and Charities

We wish you a Delightful Christmas, and a Healthy, Peaceful and Prosperous New Year. Thank you for working with us during the continuing challenge that was 2021. We are closed at 5pm on Thursday December 23 2021, and reopen again at 9am Monday January 4 2022 Each year at Christmas, we support charities which have […]

Read More

Autoclave resistant medical device adhesive

Dymax MD® 1040-M is a new, versatile autoclave resistant medical device adhesive, coating, and encapsulant. Resistant to numerous cycles of sterilisation, Dymax 1040-M is suitable for consideration in a range of medical devices and surgical tools. This light curable material cures in seconds on exposure to UV light, and contains no solvents, to deliver a […]

Read More

Sustainability – little steps

We have changed our packing tape to a paper-based version. We used to use plastic. We finally found something that’s paper-based and effective in protecting and packing your goods for shipment. We already use 100% recycled cardboard boxes and biodegradable infill. It’s a small thing, in the big scheme of things. But it adds up. […]

Read More

Dispensing needles and consumables at your fingertips

Honing in on your optimal dispensing process often comes down to a degree of trial and error – even experienced operators sometimes choose the wrong tip at first. Material rheology and dispensing behaviour can be surprising. To help you evaluate and establish your dispensing process, we have released the DCK800X dispensing component kit. Containing over […]

Read More

Protect your electronics in seconds with UV light and rapid moisture cure encapsulants

Dymax UV cure electronics encapsulants with secondary moisture cure resolve the challenge of encapsulating chip and component geometries which have shadowed areas under component bodies or leads. The bulk of the material cures in seconds with light, while the balance cures with ambient moisture. Light-curable formulations are becoming increasingly popular due to their significant benefits […]

Read More

Case study: silicone gasket robotically applied lets lighting manufacturer shine

Providing light where there was once darkness, lighting assemblies have been a staple in modern vehicle manufacture for decades. For many manufacturers, the search for brighter, better-performing systems has led them away from traditional bulbs and lamps towards more complex arrays of LED emitters, with lifespans in the 1000’s of hours. Keeping these assemblies protected […]

Read More

Sealing the Deal – liquid gaskets

We were thrilled to open this month’s issue of Eureka magazine to find our article about liquid gaskets on page 27. Our colleague Matthew Baseley did a great job on this. You can read about the considerations of moving to this technology, away from solid preformed or stamped gaskets, including a discussion about return on […]

Read More

Shock exclusive “superglue” exposé in The Sun newspaper!

We fell upon on this article in The Sun today: Idiot Insulate Britain eco-mob using harmful superglue that’s TOXIC to environment to plaster themselves to roads. We are not habitual readers of this newspaper; perhaps this article is a good example why, as it is hyperbolic, hysterical, inaccurate and badly written. It does inspire us […]

Read More

Case study: increasing product design opportunities with Born2Bond Ultra HV CA

As consumers increasingly prefer smaller, more portable, wearable electronic devices, assembling the intricate components can prove challenging. This challenge is further compounded when considering skin contact material requirements and the bonding issues these materials can pose. Fortunately for a wearable electronic device manufacturer, our Born2Bond™ Ultra HV was able to address their bonding challenges while increasing their […]

Read More

Low outgassing conformal coating meets ASTM E595 & MIL-STD 883

Dymax 9771 Dual-Cure Light and Moisture-Cure Conformal Coating is now available. This low outgassing material is the first conformal coating that meets ASTM E595 and MIL-STD 883 and is therefore suitable for the aerospace and defence markets in applications including missile, satellite, and space critical printed circuit board assemblies. This coating has UL 94 V-0 […]

Read More

Take the guesswork out of your THINKY mixing process development

Turning your THINKY planetary mixing machine up to 11 for a long period of time may mix most materials homogeneously, but for other, heat sensitive components, it could do more harm than good. To enhance your process understanding and help keep those mixing speeds optimal, our partner, mixing and degassing machine manufacturer THINKY, has created […]

Read More

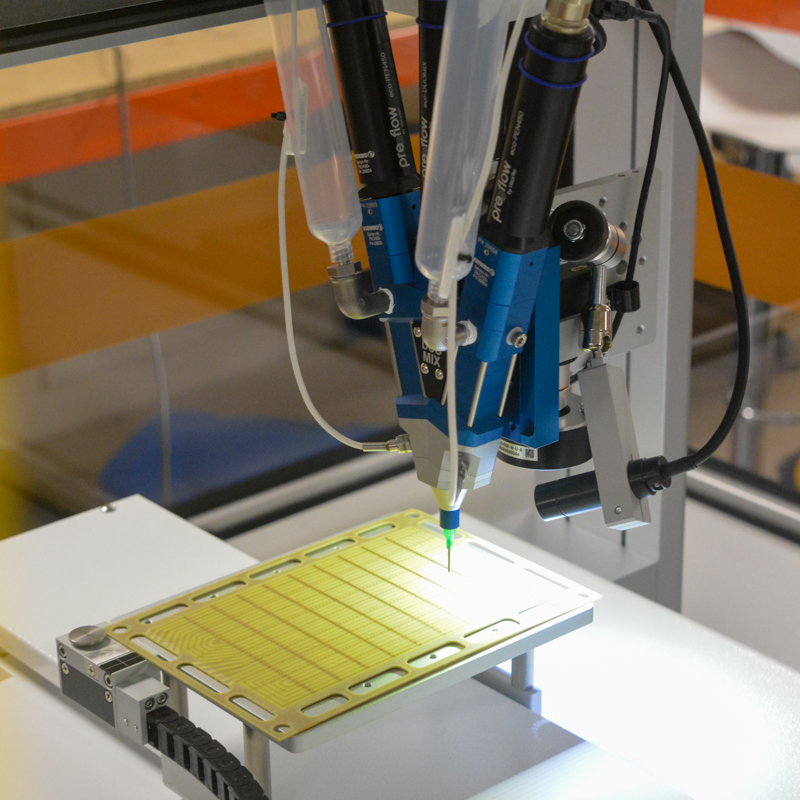

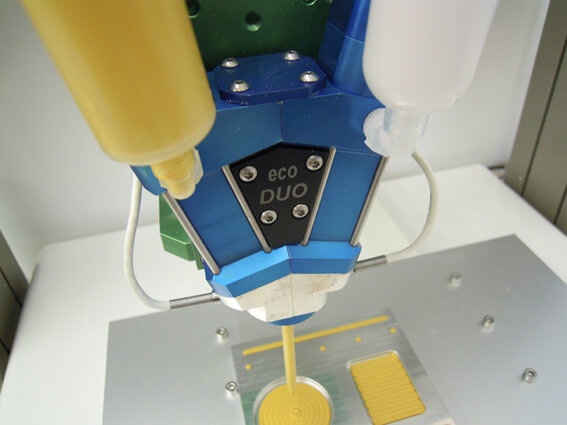

Case study: improving sealing quality while maximising productivity in gas sensor manufacture

When gas sensor manufacturer DD-Scientific wanted to improve the accuracy, repeatability, and productivity of an epoxy sealing process, they asked us. DD-Scientific now benefits from robot-mounted preeflow® eco-DUO precision metering, mixing and dispensing systems, which save the company 23 days of staff time per year, while maintaining the high-quality the company’s products demand. DD-Scientific’s sensors […]

Read More

Achieving a fast, repeatable mixing process without air bubbles

Transforming multiple parts of liquids, pastes and powders into homogeneous, ready-to-use materials which are air and bubble free – that’s what our THINKY planetary mixers do. Our newly released Technical Bulletin Achieving a fast, repeatable mixing process without air bubbles summarises the capabilities of these machines: Planetary mixing Degassing Mixing under vacuum Which capabilities you […]

Read More

Designing-In Light Curing Adhesives for Medical Device Assembly

Will you be at the Med-Tech Innovation Expo this year? The show, which runs from 28-29 September 2021 at the NEC in Birmingham, will feature a short seminar from our Managing Director, Peter Swanson. Designing-in Light Curing Adhesives for Medical Device Assembly will present an overview of UV and visible light curing adhesives and what […]

Read More

White Paper: Nailing your UV curing adhesive process

Process speed and simplicity are just two of the many productivity benefits that light curing adhesives and coatings bring to the table. If this is a new process for you, or you are setting up production on a new product, then you will want to figure out how to get it working reliably and repeatably. […]

Read More

New product: PU potting compound in cartridges

IRS 3078 Polyurethane Potting Compound is a semi-rigid, room temperature curing and electrically insulating black polyurethane potting compound. The material, which is low viscosity, semi-thixotropic and flowable, is available in convenient side-by-side double syringe cartridges. This packaging suits customers with smaller volume or occasional production needs. It offers high adhesion, good electrical insulation properties and […]

Read More

Achieving return on investment (ROI) with a mixing process

When mixing liquids, pastes and powders during an industrial process, you may identify issues that lead you to consider alternative methods. Common areas for improvement include variance due to a manual process, difficulty validating the process, or a high defect rate. You may also have productivity reasons to change your mixing processes, such as to […]

Read More

Case study: putting electronics into an archery arrow with novel CAs

Application In today’s technologically-advanced world, consumers want products that are better, smarter and more intuitive to their needs. For brand owners and manufacturers, this means continuing to push the boundaries on innovative, increasingly-smaller devices that can give consumers new product options unlike anything they’ve seen before. The miniaturisation of devices can pose assembly and bonding challenges, […]

Read More

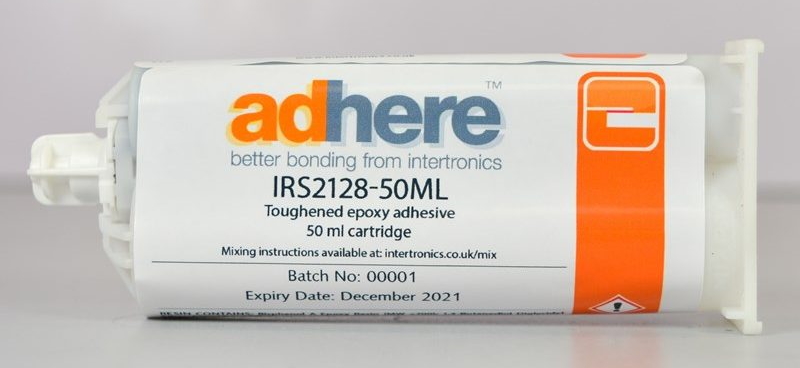

New product: toughened epoxy adhesive

We have introduced IRS 2128 Toughened Epoxy Adhesive. This structural adhesive is a high-performance black resin system that offers good chemical resistance and excellent adhesion to a wide variety of substrates. Compared with many other epoxies, it offers vibration resistance and can bond dissimilar substrates more effectively. A two-part system with a simple 1:2 mix […]

Read More

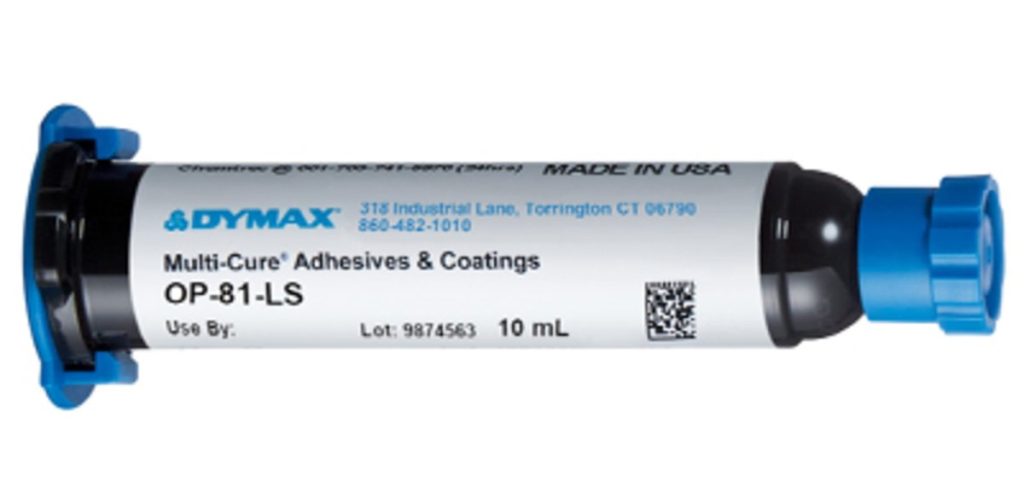

Very low shrinkage optical adhesive

We have introduced Dymax Low Shrink™ OP-81-LS UV adhesive, which offers very low volumetric shrinkage. Designed for optical assembly applications that require precise alignment, the material cures in seconds on exposure to UV/visible light. It is single-part, solvent free and can bond dissimilar substrates — it is recommended for materials including polycarbonate, glass, acrylic, metal, […]

Read More

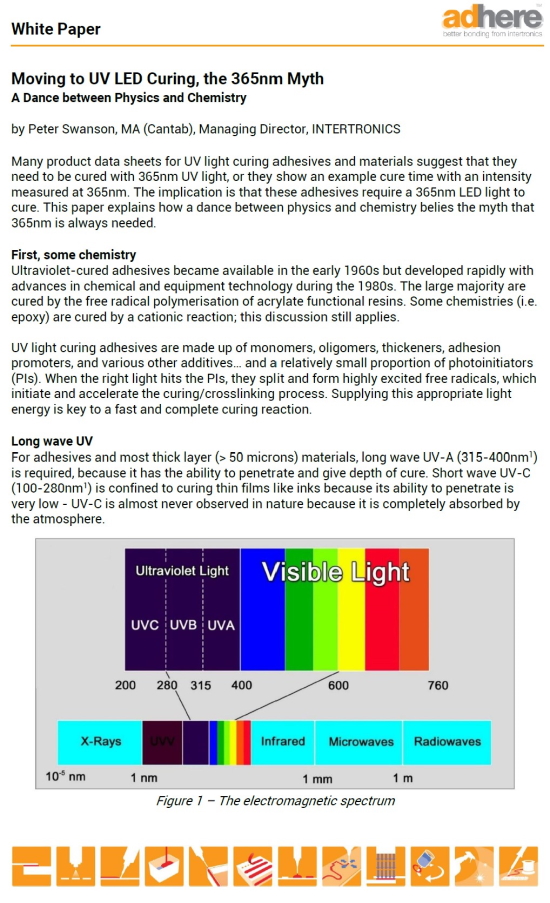

White Paper: Moving to UV LED curing, the 365nm myth – a dance between physics and chemistry

Our latest White Paper, entitled Moving to UV LED Curing, the 365nm Myth – A Dance between Physics and Chemistry, discussed the assumptions around using UV LEDs to cure adhesives, coatings, sealants, encapsulants and temporary masking materials. Despite some hints on product data sheets, 365nm may very well not be the best wavelength to pick […]

Read More

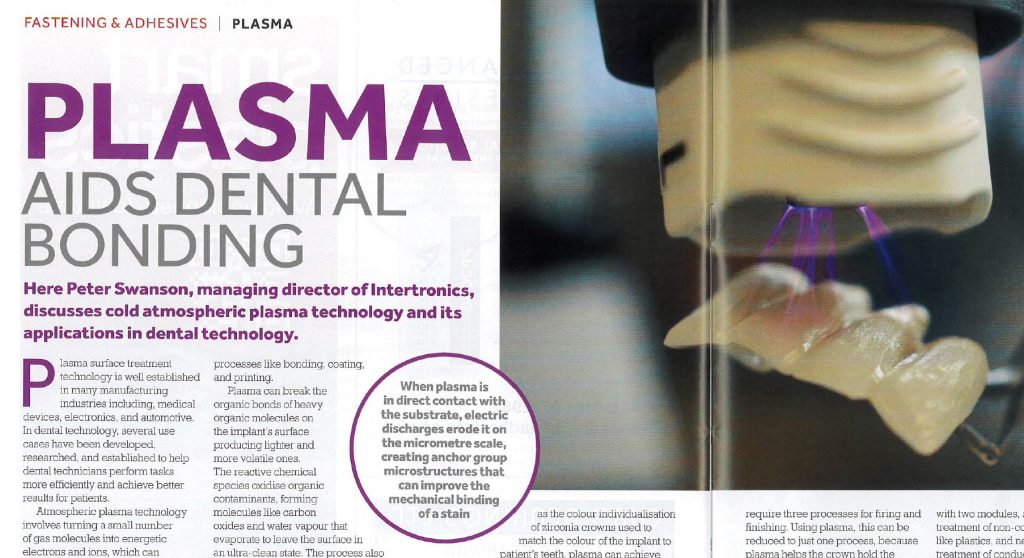

Article: plasma aids dental bonding

Eureka is a very highly regarded engineering magazine, so we were excited to see a two-page spread in the latest issue given over to our article Plasma Aids Dental Bonding. See page 32 to read how cold atmospheric plasma technology delivers benefits in dental labs. It features the PiezoBrush PZ3, the world’s smallest, highly effective […]

Read More

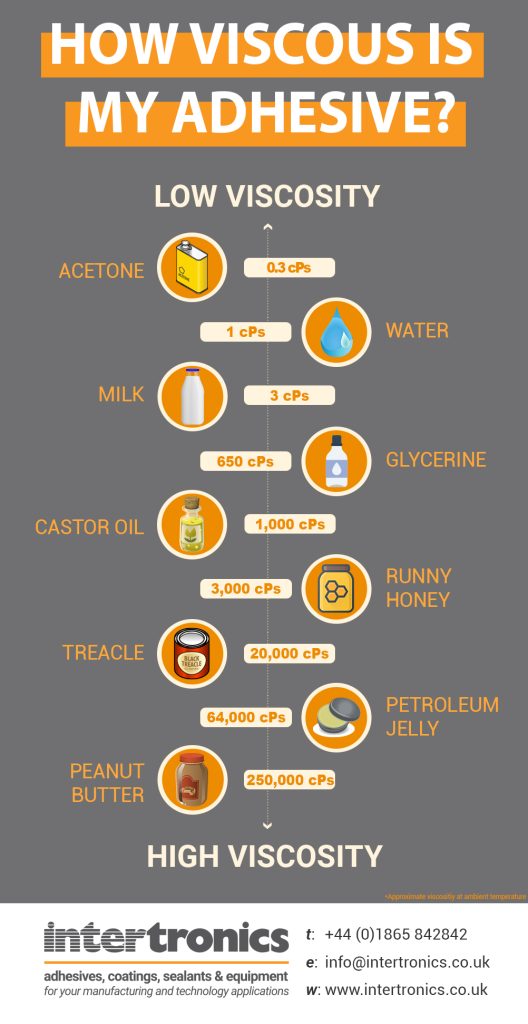

adhere academy: what is viscosity?

Viscosity is the resistance of a fluid to flow. This means that different fluids with different viscosities will flow at different rates under the same force. The higher a viscosity a fluid has, the harder you have to push it to move it. We call a higher viscosity fluid more viscous. You can see why […]

Read More

Video: vacuum mixing, degassing, and set-up of THINKY ARV-501 Mixer

Our partners at THINKY, makers of planetary centrifugal mixers, have produced a video detailing how to use the THINKY ARV-501 vacuum mixer, with or without the vacuum mixing functionality. In this video, you can see how the user interface works, how to set up a program, and learn about the mixer’s PC interface: The […]

Read More

Plasma surface treatment in dental applications offers efficiency and better results

Plasma surface treatment technology is well established in many manufacturing industries including medical devices, electronics, and automotive. In dental technology, several use cases have been developed, researched, and established to help dental technicians perform tasks more efficiently and achieve better results for patients. Plasma can initiate several physical and chemical processes that both clean and […]

Read More

Case study: bonding 3D printed parts

3D printers usually print relatively small stuff – certainly less than 1 meter in any dimension. Our own 3D printer’s largest build dimension is 320mm, and that is fairly common. There are exceptions, of course – these days you can 3D print a two-story house. But for most applications, if you need to make a […]

Read More

Seven considerations in medical device design

A great article in Med-Tech Innovation News lists seven considerations for medical device design; it was written by Dan Purvis of Velentium, a company specialising in the design and manufacturing of therapeutic and diagnostic active medical devices. It’s worth reading the whole thing, but consideration number 5 caught our eye: Design with manufacturing in mind […]

Read More

Mercury bans and UV curing lamps

An article in this week’s Electronics Weekly about the use of short-wave UV LED’s in the fight against Covid-19 contained this statement: “New international legislation which came into force in January 2020 means that mercury-based lamps are, with very few exceptions, no longer an option. The manufacture, import and export of mercury lamps is now […]

Read More

What Makes a Good Adhesives Partner?

What makes a good adhesives partner? That’s a great question! We decided to answer it by getting a group of us together and thrashing it out. The results of our roundtable talk might surprise you. Please read the summary of our discussion, get some insight into the way we think, and see if you agree.

Read More

Simple adhesive processes and standard robotic solutions

I was struck by an article today on the Industrial Technology website: European Manufacturing Breakthroughs Stifled by Overengineered Industrial Robots. The article quotes Torsten Christensen, partner and co-founder at ChangeForce, a Danish industrial consultancy firm. According to him, the most popular reason behind disappointing robotisation implementations is the complexity and over customisation of technologies installed. […]

Read More

Flame-retardant UL 94 V-0 silicones improve product safety

Flame-retardancy is a common requirement for materials used to make products that need to meet certain safety standards, such as home appliances, automotive systems, and electronics. A flame retardant is a chemical substance that is added to materials during their manufacturing process in order to both reduce the likelihood of the finished product catching fire and […]

Read More

White Paper: Adhesive selection: a race against the clock?

One of our recently published White Papers discusses time-based considerations when specifying adhesives for any application. Not only are you looking for an adhesive that bonds well to your required substrates, but one which also meets the functional requirements of its application. In addition to these, there are also time-based considerations to factor in. Read […]

Read More

Investing in adhesives – why ROI is more than just the payback period

Selecting an adhesive One of the major considerations when specifying an adhesive is how quickly it will deliver return on investment (ROI), a metric that is affected by a variety of tangible and intangible factors. If you’ve ever tried to source an adhesive for your application, you probably realised quickly that there is no universally perfect […]

Read More

Cover star – avoiding potting voids article

The latest issue of Global SMT & Packaging features our White Paper on the cover. Potting and encapsulating – avoiding voids was written by Paul Whitehead, our Strategic Accounts Manager. It discusses potting voids – what are they, why they are bad, and how to prevent them happening. Click through to read this issue, with […]

Read More

preeflow volumetric dispensing pumps – a decade of proven preeminence

Congratulations! Our dispensing partner Viscotec, makers of preeflow, have announced that in 2020 they passed a milestone of supplying more than 100,000 dispensing pumps into industry, including 65,000 preeflow volumetric dispensing pumps. We have been providing these precision dispensers to manufacturers in the UK and Ireland for a decade now, and have facilitated their success […]

Read More

What is a jetting valve and when should I use it?

Jetting valves enable high-speed, continuous, non-contact dispensing of dots of small size, offering a high degree of accuracy and repeatability. During the jetting process, a small chamber is filled with material and ejected by firing a tappet through the chamber ― using either piezo or high energy pneumatics to achieve very fast tappet movement ― […]

Read More

White Paper: Potting and encapsulating – avoiding voids

Our latest White Paper tackles the issue of voids in potting compounds and encapsulation. Potting and encapsulating – avoiding voids was written by Paul Whitehead, our Strategic Accounts Manager. It discusses voids – what are they, why they are bad, and how to prevent them happening. If you are involved with electronics potting or encapsulation, […]

Read More

Working in the adhesive industry

“The adhesive industry is the place to be for all the curious ones who want to deliver value!” One of our friends and colleagues, Robert Ignatzek, recently wrote this on LinkedIn. Robert is a 20 year veteran in the business, and an all round enthusiast for our sector. We responded to Robert, and he was […]

Read More

Adhesive productivity from the get go

When you are experiencing poor productivity from an adhesives process, the first step to resolving the issue is to identify why — there are several common pain points, including speed, quality and waste. If you identify that a material is holding you back, what can you do to reach your productivity potential? Compared with mechanical […]

Read More

White Paper: UV light and moisture curable electronics encapsulants

Encapsulants are often required to protect electronic components against moisture, chemicals, and rapid and extreme temperature changes while providing mechanical support and electrical insulation. Light-curable encapsulating compounds can provide significant benefits over conventional technologies, including very fast curing, lower operating costs and increased productivity driven by lower labour requirements, space savings, lower energy demand, and […]

Read More

Accurate, precise dispensing for wearable technology

The comfort, flexibility and connectivity of wearables have been made possible through progress in sensor technology, power management and transmitter technology; these advances in wearable technology require improvements to the production process. One important part of the assembly process is the dispensing of materials like adhesives, silicones, thermally and electrically conductive materials and greases. Dispensing […]

Read More

North Oxfordshire Community Foodbank and our elf

This year, we again asked all our colleagues to collect food and other vital supplies to be distributed by the North Oxfordshire Community Foodbank. Our elf, D Spencer, helped our team sort, pack and ship the haul over to the Foodbank. James manages this operation each year, and he does a great job. This year […]

Read More

Holidays and Charities

We wish you a Delightful Christmas, and a Healthy, Peaceful and Prosperous New Year. Thank you for working with us during the challenge that was 2020. We are closed at 5pm on Wednesday December 23 2020, and reopen again at 9am Monday January 4 2021. Each year at Christmas, we support charities which are either […]

Read More

Handheld high-intensity LED UV curing flood lamp provides flexibility

Our customers sometimes want to take advantage of UV curing on large or complicated assemblies, where a bench-mounted UV curing lamp will not allow ready access to the target areas. Some examples which spring to mind are the bonding of large PMMA point-of-sale assemblies, or the temporary masking of turbine blades. You also want to […]

Read More

e-book: 7 ways UV temporary masking helps in electronic assembly

This new e-book from our partners Dymax is entitled Smart Connected Device Assembly – 7 Ways Light Curable Maskants Can Provide Protection. Covering seven different electronics assembly processes, including soldering, coating, and surface treatments, the benefits of uv light curable temporary masking products are clearly described. It is worth downloading a copy!

Read More

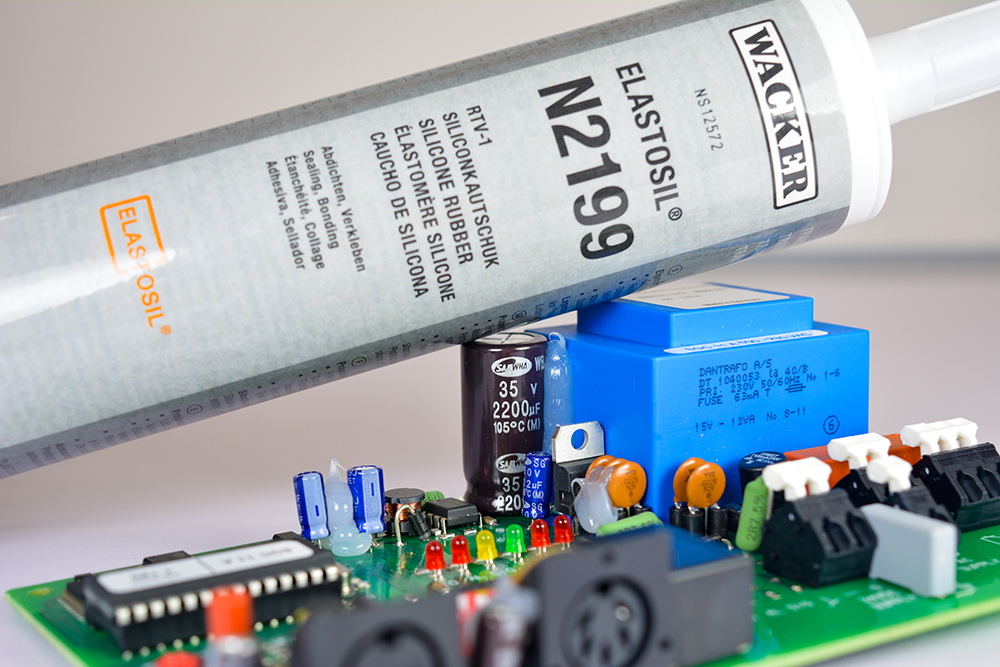

New silicone adhesive sealant offers translucency and flexibility

When aesthetics are an important consideration alongside reliable sealing performance, a clear silicone is worth considering. Wacker ELASTOSIL® N2199 is a highly flexible, translucent silicone which meets the criteria of MIL-SPEC 46146, Group I, Type I. N 2199 is a one-part, ready-to-use, acid- and sovent-free, RTV-1 nonslumping paste that cures at room temperature to a […]

Read More

Panel Discussion tomorrow: potting, encapsulating and underfills

We are delighted to have the opportunity to join this Panel Discussion tomorrow. Potting, encapsulating and underfills are all essential procedures in the assembly process. With miniaturization makes accurate, void-free processing important to maintain adequate support, protection and reliability. The panel will discuss the do’s and don’ts of these processes, followed by a Q&A session. […]

Read More

New: 700g vacuum centrifugal planetary Thinky mixer

If you are mixing ultra-critical applications where even micro-bubbles cannot be tolerated, you may need the latest industrial non-contact vacuum planetary mixer, the THINKY ARV-501CE. The unit has a maximum capacity of 700g for mixing, de-foaming and degassing any combination of liquids, powders, and pastes. It is suitable for all engineering compounds, from low viscosity to […]

Read More

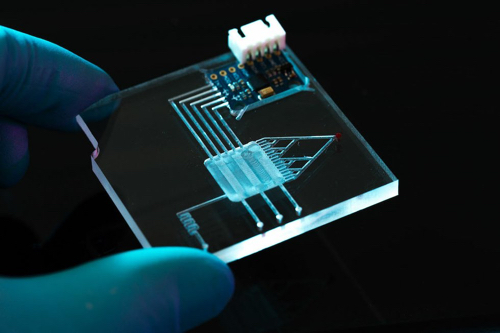

How to bond COC/COP film laminates

Dymax MD® 1172-M-UR is an LED UV and broad-spectrum light-curable adhesive for bonding COC/COP film laminates and other difficult-to-bond-to plastics used in the assembly of in-vitro diagnostics (IVD), Lab-on-a-chip (LOC), and other point-of-care medical devices. This adhesive may also be of interest to manufacturers involved with the design of COVID-19 rapid diagnostic applications. The adhesive […]

Read More

Dispensing: covering all your processes with one technology

Dispensing and dosing small quantities (microlitres) with volumetric precision can be a headache for many companies in sectors such as electronics and semiconductor manufacturing, aerospace, medical device assembly and pharmaceuticals. Having to maintain accuracy whilst also meeting throughput and productivity demands may have traditionally pushed manufacturers towards complex, multi-system processes in order to achieve their […]

Read More

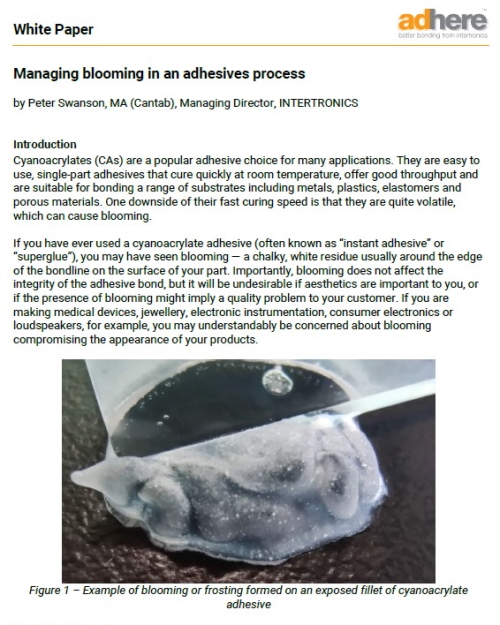

White Paper: What is cyanoacrylate adhesive blooming, and what can you do about it?

What is cyanoacrylate adhesive (CA) blooming, and what can you do about it? That is the subject of our latest White Paper, entitled Managing blooming in an adhesives process. The article discusses what is blooming, how it happens, and methods to reduce or eliminate it. Importantly, blooming does not affect the integrity of the adhesive […]

Read More

More ways to improve your productivity through dispensing automation

Adopting robotics for dispensing automation into your production process can contribute considerably to an increase in operational efficiency and productivity. As robotics technology advances, consistency and overall process control becomes ever more attainable and affordable. You may be surprised at how quickly return on investment can be achieved with dispensing robots, particularly when time savings, […]

Read More

Game changing two-part cyanoacrylate adhesives available in convenient cartridges

Born2Bond two-part cyanoacrylate adhesives bring game-changing advancements to the world of adhesives, overcoming many of the performance and application limitations of existing cyanoacrylate adhesives. Born2Bond Structural is the toughest structural, fast cure two-part (2K) cyanoacrylate adhesive on the market, with the longest open time. Born2Bond Flex is the only two-part cyanoacrylate adhesive on the market […]

Read More

New product: 2-K-DOS Metering, Mixing and Dispensing System

The mixing and dispensing of two-part potting compounds, encapsulants and similar products has to be one of the trickiest production processes to get under control. If you are looking to scale up or streamline your existing process, we are now able to offer the 2-K-DOS Metering, Mixing and Dispensing System. It is based on gear […]

Read More

Food compliant silicones

Under European Regulation (EC) No 1935/2004, materials such as silicones can be rated food-compliant where they are manufactured using practices that “under normal or foreseeable conditions of use, they do not transfer their constituents to food in quantities which could endanger human health, bring about an unacceptable change in the composition of the food, or bring about […]

Read More

Article: Cold plasma in electronics industry

The latest September 2020 issue of Global SMT & Packaging (The Global Assembly Journal for SMT & Advanced Packaging Professionals) contains an article from us entitled Cold Plasma in Electronics Industry. Adhesion plays a decisive role for product quality and process stability in many areas of the electronics industry. These include bonding and marking of […]

Read More

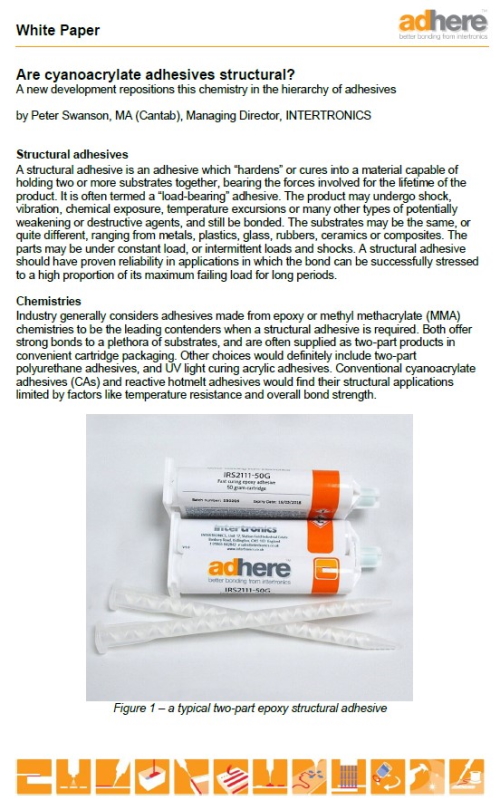

White Paper: Are Cyanoacrylate Adhesives Structural?

This new White Paper, entitled Are cyanoacrylate adhesives structural?, looks at the role of cyanoacrylate adhesives in load-bearing, structural applications. It discusses a new development which repositions this chemistry in the hierarchy of adhesives. Click on the image to read the full article. We have this White Paper and many other technical resources, including articles, […]

Read More

Adhesive process choices – best available option

The best available option. That’s not the same as perfect. The best available option is always available. Perfect almost never is. Adhesive choice is always about compromise. Worthwhile debates: ultimate adhesive functionality versus process-ability the cost of the adhesive versus the cost of processing it the robustness of the adhesive versus rework-ability or end-of-life recycling The perfect […]

Read More

Medical-grade ISO 10993 silicone adhesive for bonding silicones and textiles

Wacker’s SILPURAN 4200® medical-grade silicone adhesive is a single-part transparent, room temperature vulcanising (RTV) silicone adhesive that is suitable for bonding cured silicone parts and highly elastic bonding between silicone and textiles, such as in ventilation masks and respiratory bellows. Formulated with a new catalyst which does not use organotin compounds, SILPURAN 4200 is ISO […]

Read More

Case study: high-quality glass repair in short timelines with Opti-tec 5013 clear epoxy

Anthony Scala, a London-based glass artist and instructor, takes on repair work for glass pieces ranging from sentimental value to more significant worth. In order to complete repairs in a timely manner, Anthony sought an adhesive that offered a fast curing time whilst maintaining good clarity and structural reliability. Opti-tec 5013 Optically Clear, Fast-Curing Epoxy […]

Read More

How do I validate my UV curing process?

If you are establishing a new process involving the UV light curing of an adhesive or another light curing material, we can highly recommend these resources. All are from our partners, Dymax. First, a couple of articles entitled Validating a UV Flood Curing Process and Validating a UV Spot Curing Process. Secondly, a couple of […]

Read More

Unique dual cure UV cyanoacrylate adhesive with low odour and low blooming

Cyanoacrylate adhesives (CAs) cure best interfacially, i.e. between two surfaces, and in thin bondlines. In adhesive joint formats where there are exposed CA surfaces, fillets, or normal squeeze-out, those parts can take a long time to cure. This may inhibit the flow of a product to the next process in production, or attract contamination when […]

Read More

How do I glue back these toes?

You may have heard this story in the last day or so: a tourist snapped off the toes of a 200-year-old Italian sculpture while sitting on it for a photograph. The museum is in Possagno, Italy, and specialises in the work of the 18th-century sculptor Antonio Canova. Ouch! The conservation and repair specialists could consider […]

Read More

New options for preeflow eco-PEN precision dispensers increase usability and robustness

Precise, process-safe applications in the field of microdispensing are the focus of preeflow dispensing systems. They employ the endless piston principle to provide accurate, repeatable volumetric dispensing of almost all materials, be they low or high viscosity. Some materials and environments have more rigourous demands for dispensing equipment, so preeflow has developed two new options […]

Read More

Productivity gains for less than £370 with a dispensing controller

We’re on a mission to help UK manufacturers squeeze more productivity out of their bonding and materials application processes. While it is not usually difficult to figure out the investment justification on the equipment that we offer, there also isn’t a high upfront cost for improving your dispensing process from a manual one to one […]

Read More

Kevin Kelly: “Don’t trust all-purpose glue.”

Kevin Kelly recently turned 68 years old. Amongst many achievements, he is a co-founder of Wired magazine, and was publisher and editor of the Whole Earth Catalog. He celebrated his birthday by giving us 68 Bits of Unsolicited Advice. There are many gems of wisdom there, and I do encourage everyone to read them. Some […]

Read More

Getting your trials done with a live video meeting

In our determination not to let the pandemic keep us down, we have been pursuing further methods to help our customers push their businesses forward. We have always provided a service for helping you evaluate materials and equipment by providing testing in our Technology Centre. Often the results are provided to you in a written […]

Read More

World’s smallest, highly effective handheld plasma treatment device

The PiezoBrush PZ3 Handheld Plasma Surface Treatment Device from Relyon Plasma is suitable for use in manual or semi-automated production, new product development, and in research and development settings such as a laboratories. It is simple, safe and intuitive. With a maximum power consumption of 18W, its unique Piezoelectric Direct Discharge (PDD®) technology is used […]

Read More

Who was Archytas, and what does he have to do with adhesive automation?

We recently launched our archytas series of robot integrations, which are robotic dispensing, UV curing and/or surface preparation systems custom-built to meet your application requirements. Understanding the idea behind the systems is simple enough, but what’s the idea behind the name? Archytas (ARK-it-ahs) was an Ancient Greek philosopher, mathematician, astronomer, statesman, and strategist. He is […]

Read More

Powerful, compact LED UV spot curing system enables up to four concurrent spot cures with ease and flexibility

LED UV light curing systems have gained popularity in recent years, and are becoming the technology of choice and more cost-attractive. The BlueWave QX4 LED UV Spot Curing Lamp offers all the benefits of LED UV over traditional broad-spectrum technology including instant on/off with no warm-up, low operating temperature, decreased energy consumption and up to 20,000 hour […]

Read More

A big step forward in the technology of cyanoacrylate adhesives

Cyanoacrylate adhesives (CAs) have been around since the 1950s, and from the 1970s they have become a common household product. Today, manufacturers are increasingly using CAs and rely on them to bond plastics, metal, ceramic, rubber, wood and other substrates in many types of assemblies. They are unique in that they provide fast curing and […]

Read More

Dispensing: what do we mean by accuracy and repeatability?

A number of the products that we offer are described as being highly accurate, precise and/or repeatable. We believe that these criteria are important to a process where consistent, high quality output is required, and they have a big impact on productivity through reduction of material waste, quality-based rejects, and rework. But what exactly do […]

Read More

adhere academy: UV curing tips and tricks

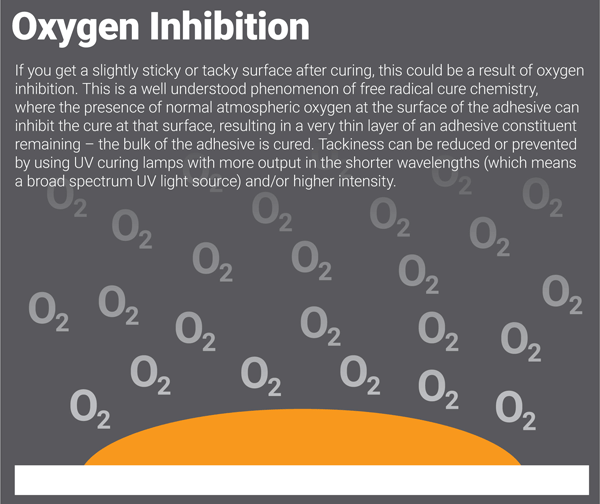

Bonding effectiveness, rapid cure time and process efficiencies have made light curing materials popular for manufacturers for assembly applications. Here, we share three tips for your UV curing processes. With a clear understanding of the UV curing process and the technology available, you can make informed choices and optimise your process. Broad vs narrow spectrum lamps The […]

Read More

Thank you for what you do

In the past few weeks, we have seen many of our customers retool and/or increase production to meet the current needs of the NHS, the health industry and its users in the face of a global pandemic. In several cases, this has involved teaming up with other organisations to pool expertise and share resources. Even […]

Read More

What is your productivity potential?

We launched the What is your productivity potential? campaign to help manufacturers improve your productivity and become more competitive on a global scale. It highlights the ways that assembly companies can simplify processes, improve output and reduce waste. Currently, in Spring 2020, manufacturing companies are facing different kinds of challenges. Some are frantic, assembling ventilators, […]

Read More

How to load syringes from a 310ml cartridge

It is almost impossible to make precision manual application of materials like RTV silicones from their standard packaging – a 310ml cartridge. You have probably run a seal around your bathtub from such a cartridge, but if you want to apply a dot of a millimetre or two diameter to a complex printed circuit board, […]

Read More

Adhesives, protective materials and equipment for medical device assembly

Our new brochure details the products we offer to those assembling medical devices. They include ISO 10993 adhesives and associated mixing, dispensing and curing equipment – all designed to help you achieve process reliability, repeatability and validation. As a medical device manufacturer, you need: Adhesives and protective material which bond to your substrates, withstand the […]

Read More

New product: preeflow® eco-DUOMIX450 precision metering, dynamic mixing and dispensing system

The metering, mixing and application of two-part materials is always a tricky business, more so when the required amounts are relatively small – in the sub-millilitre range. If the two parts are of quite different viscosities, or the mix ratio is much greater than 1:1, or there are fillers involved, then it is even more […]

Read More