I was struck by an article today on the Industrial Technology website: European Manufacturing Breakthroughs Stifled by Overengineered Industrial Robots.

The article quotes Torsten Christensen, partner and co-founder at ChangeForce, a Danish industrial consultancy firm. According to him, the most popular reason behind disappointing robotisation implementations is the complexity and over customisation of technologies installed. Thomas Ronlev, the CEO at Factobotics, suggests, “European manufacturers often believe their production processes are unique. They are also often convinced that entire production and supply chains be automated. I think that truth is much more down to earth: some processes are indeed ripe for automation, but not all of them, let alone at once. We would see a much higher degree of satisfaction if companies started from simple processes and standard robotic solutions that come at a fraction of the cost and are easy to master. Some of the most successful factories use relatively simple robotics.” I recommend reading the whole thing.

Well, simple processes and standard robotic solutions is what we offer in the world of adhesives, gaskets, coatings and sealants.

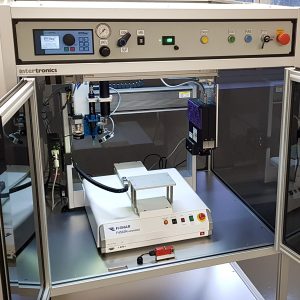

You can’t get more simple nor more standard than our Fisnar F4200N.2 Dispensing Robot – as you can see in this video, it is also highly capable, very configurable for other dispensing jobs, and gives a fast return on investment.

If you need to combine a few simple processes, then with our archytas series of robot integrations, we have the capability to assemble material mixing, dispensing and application, curing, and/or surface preparation on one machine.

Don’t fall for “lots of hype coupled with a low return on investment, heavy reliance on third-party integrators and, quite often, complex machines not returning the expected value.” Get in touch.

– Peter Swanson, Managing Director

Posted by Peter Swanson

Peter is the Founder and Executive Chair of Intertronics. He is mostly involved in strategy, recruitment and helping out the Marketing team.

Who's Peter?