Recent advances in semiconductor and microelectromechanical systems (MEMS) have reduced both their size and cost. The Advanced Textiles Research Group at Nottingham Trent University is incorporating these components into the yarn-making stage to broaden the possibilities for electronic textiles into areas like temperature sensing, medical monitoring, motion sensing, energy harvesting and illumination. By incorporating the components into the yarn fibre, the fabric retains the textile properties, such as tensile recovery, drapability and breathability. The market is expected to grow significantly over the next few years, with the size of components diminishing leading to a broadened number of applications.

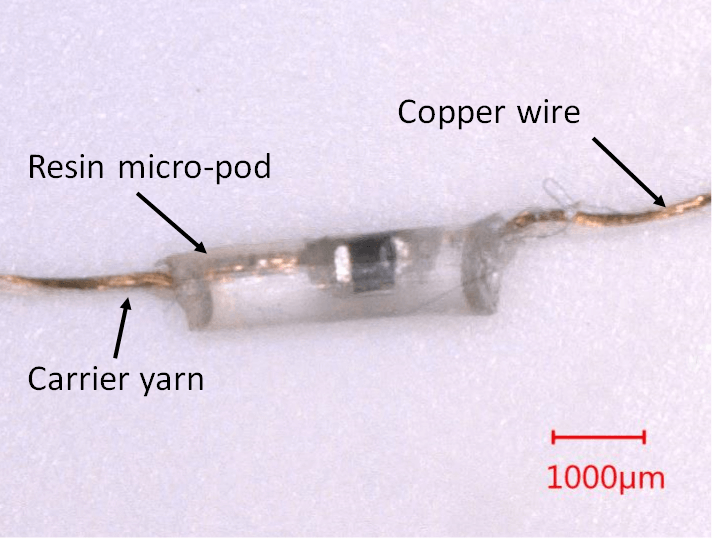

During the yarn-making process, the group encases microchips with a polymer micro-pod to protect them from mechanical and chemical stresses. The team approached us for assistance with automating the micro-pod process.

“We visited the Advanced Textiles Research Group to discuss the challenges the researchers were facing, and to fully understand the process they wanted to achieve,” explained Matt Baseley, our Senior Internal Technical Sales Specialist. “Following our discussions, we suggested a few Dymax electronics-grade UV-curing encapsulants that were flexible and transparent. They tested some samples and found that Dymax Multi-Cure 9001-E-V3.5 met their needs. Next, we discussed volumetric dispensing as an alternative to time/pressure dispensing, to remove variations from their process. By dispensing volumetrically with the preeflow eco-PEN, they can have confidence that a consistent amount of encapsulant is dispensed every time. Once they had chosen the material and equipment, we helped them to fine-tune the micro-pod process to overcome any remaining challenges they were facing.”

A close-up view of an encapsulated thermistor ready for weaving into yarn

“Intertronics were able to give us off-the-shelf solutions, fine-tuned to our needs,” explained Theodore Hughes-Riley, Senior Research Fellow in Electronic Textiles at Nottingham Trent University. “This was particularly useful in helping us to set up a completely novel type of production line as quickly as possible. Through the course of several visits, Matt Baseley and Paul Whitehead worked with us to refine our process, taking the time to teach us how to use the new equipment, and suggesting improvements. They were knowledgeable and approachable, which was vital to engagement with our diverse team and requirements.”

You can read the full case study here: Electronic Textiles development at Nottingham Trent University

Categories: case study, dispensing, encapsulation, LED Curing, microelectronics, uv curing