Category: sealants

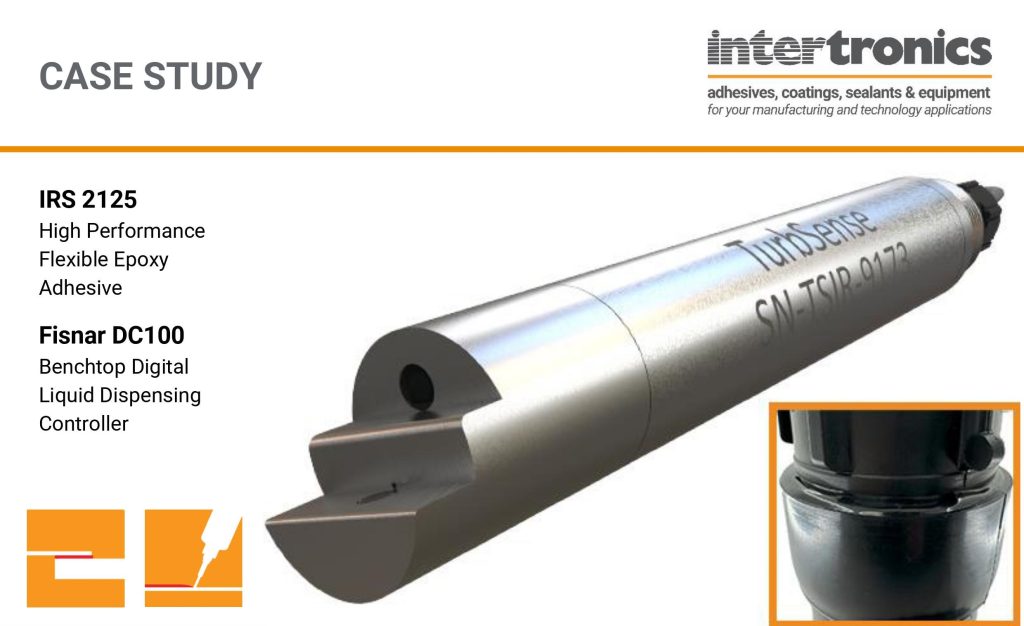

Case study: flexible epoxy drives performance

We are supplying Process Instruments (Pi), a water analyser instrument manufacturer, with our IRS 2125 High Performance Flexible Epoxy Adhesive. This versatile adhesive offered performance benefits as a thread locker on flow cells and an IP68 rated sealant on sensors. Pi manufactures and supplies water analyser instrument solutions that can reliably, continuously, and accurately measure […]

Read More

What is the difference between an adhesive and a sealant?

Our customers often use adhesives and sealants in their products, in a wide variety of applications. They can be seen as quite similar materials, and indeed have overlapping uses. Some adhesives are also used as a sealant; some sealants are also used as an adhesive. We even sell products which are termed “adhesive sealants”. But […]

Read More

Sealing the Deal – liquid gaskets

We were thrilled to open this month’s issue of Eureka magazine to find our article about liquid gaskets on page 27. Our colleague Matthew Baseley did a great job on this. You can read about the considerations of moving to this technology, away from solid preformed or stamped gaskets, including a discussion about return on […]

Read More

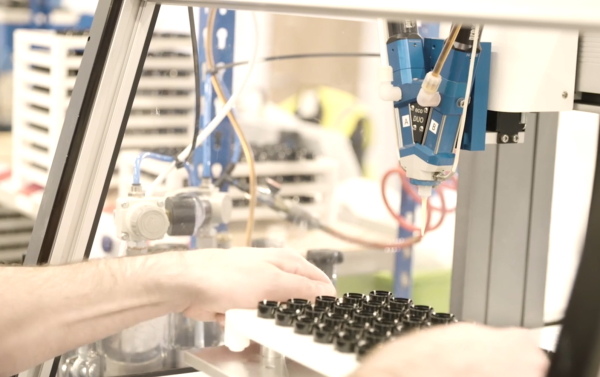

Case study: improving sealing quality while maximising productivity in gas sensor manufacture

When gas sensor manufacturer DD-Scientific wanted to improve the accuracy, repeatability, and productivity of an epoxy sealing process, they asked us. DD-Scientific now benefits from robot-mounted preeflow® eco-DUO precision metering, mixing and dispensing systems, which save the company 23 days of staff time per year, while maintaining the high-quality the company’s products demand. DD-Scientific’s sensors […]

Read More

Flame-retardant UL 94 V-0 silicones improve product safety

Flame-retardancy is a common requirement for materials used to make products that need to meet certain safety standards, such as home appliances, automotive systems, and electronics. A flame retardant is a chemical substance that is added to materials during their manufacturing process in order to both reduce the likelihood of the finished product catching fire and […]

Read More

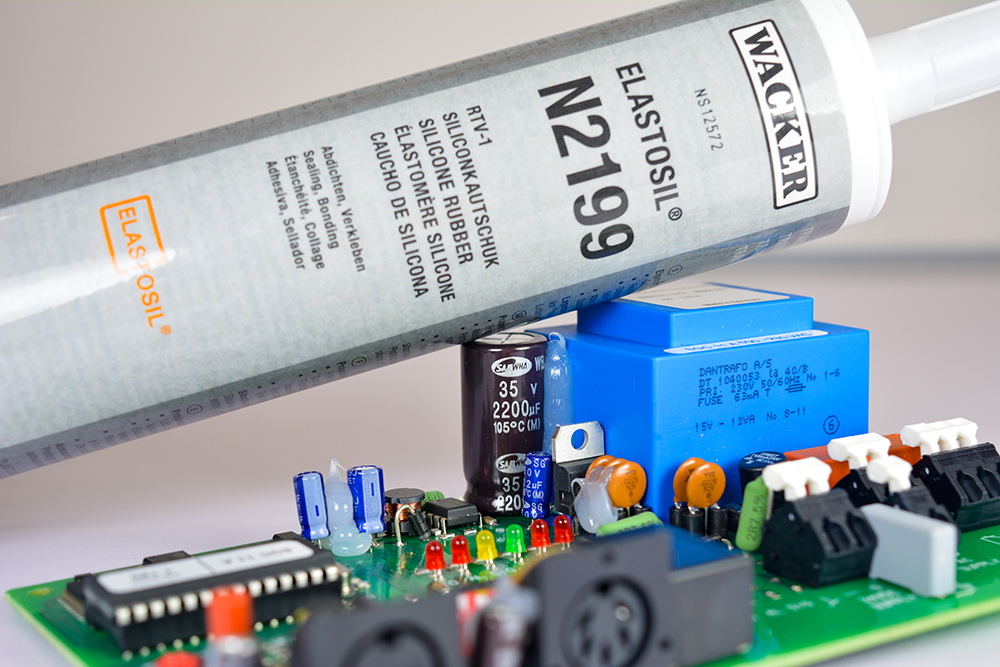

New silicone adhesive sealant offers translucency and flexibility

When aesthetics are an important consideration alongside reliable sealing performance, a clear silicone is worth considering. Wacker ELASTOSIL® N2199 is a highly flexible, translucent silicone which meets the criteria of MIL-SPEC 46146, Group I, Type I. N 2199 is a one-part, ready-to-use, acid- and sovent-free, RTV-1 nonslumping paste that cures at room temperature to a […]

Read More

Food compliant silicones

Under European Regulation (EC) No 1935/2004, materials such as silicones can be rated food-compliant where they are manufactured using practices that “under normal or foreseeable conditions of use, they do not transfer their constituents to food in quantities which could endanger human health, bring about an unacceptable change in the composition of the food, or bring about […]

Read More

How to load syringes from a 310ml cartridge

It is almost impossible to make precision manual application of materials like RTV silicones from their standard packaging – a 310ml cartridge. You have probably run a seal around your bathtub from such a cartridge, but if you want to apply a dot of a millimetre or two diameter to a complex printed circuit board, […]

Read More

Case study: preeflow precision dispensing improves automotive gasket quality

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow® customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) automotive gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point […]

Read More