It’s been 50 years since the USA softly landed a spacecraft on the Moon’s surface. Something Intuitive Machines, based in Texas, is looking to change.

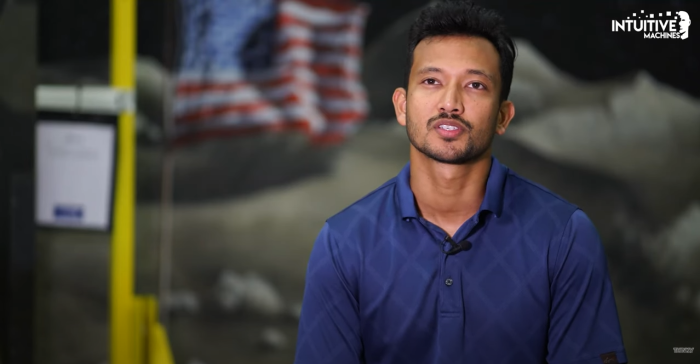

When sending expensive, often delicate, machinery and equipment into the depths of space, achieving the most reliable bonds between components is mission critical. For this very reason, Arnab Roy, Production Manager at the company, chose to use a THINKY mixing and degassing machine to homogeneously mix their two-part epoxy adhesive.

THINKY mixers use a non-contact “planetary” mixing method to transform multiple parts of liquids, pastes, and powders into homogeneous, ready-to-use materials. It’s these qualities that make Arnab and his team confident that their lunar lander will maintain its structural integrity, withstand large temperature fluctuations and resist the mechanical stresses endured during its mission.

In this interview, Arnab Roy delves into how THINKY planetary centrifugal mixers improve their production quality, save time, and reduce manufacturing costs.

“Bubble-free epoxy is essential for the structural integrity of the lander in space.”

If you need help with bonding any equipment being fired into space at high velocity, or indeed an application that will stay within our atmosphere, get in touch with our technical experts.

Categories: case study, epoxies, mixing