Our customers are doing amazing things, so we’d like to highlight some of their achievements and perhaps provide you with a bit of inspiration for ways to improve your productivity while achieving a great return on investment.

Our customers are doing amazing things, so we’d like to highlight some of their achievements and perhaps provide you with a bit of inspiration for ways to improve your productivity while achieving a great return on investment.

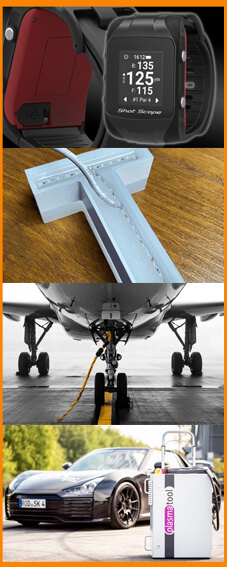

Here’s a snapshot of some of our recent case studies:

- ShotScope has been able to quadruple production of their golf GPS performance tracking watches with faster manufacturing time, reduced labour costs, and a consistently high-quality result with no defects or wasted material

- An outdoor LED sign manufacturer found a material for potting LED strips that helps to maintain consistent colour warmth and product quality

- A manufacturer of aircraft landing gear and actuation systems cut part of their electroless nickel plating process down from 3 days to 45 minutes

- Roding Automobile GmbH produces lightweight composite and thermoplastic automotive structures with improved mechanical properties, using plasma surface treatment

You can always find the latest success stories from our customers in the Case Studies section of our website.

Get in touch with our product specialists to find out more about how to improve your productivity through the materials and application techniques you use.

This blog post is a copy of a recent edition of JoinedUpThinking, an occasional email with ideas, tips, and featuring the latest technologies in adhesive materials and associated equipment. If you would like to receive JoinedUpThinking, simply let us know by filling in the form on our Contact Us page.

Categories: aerospace, automotive, case study, composites, dispensing, JoinedUpThinking, LED, masking, potting compound, productivity