Category: surface preparation

Attension User Day: Basics of Wettability

We recently acquired Dyne Testing Ltd, a supplier of surface testing and measurement products. One of our new partners is Biolin Scientific, and they are running a half-day online “Attension User Day” on June 3 2024 centred around understanding wettability and how wettability measurements can benefit your research and product development. There will be insights […]

Read More

Intertronics acquires Dyne Testing Ltd

We have completed on the purchase of Dyne Testing Ltd, a leading UK manufacturer and supplier of surface measurement technology. Dyne Testing offers a range of measurement equipment for testing surface energy and tension, surface cleanliness, adhesion, and coating thickness, to improve quality and process control in various industrial applications. This aligns with Intertronics’ existing […]

Read More

Bonding specialist medical device plastics

Medical device manufacturers are increasingly turning to specialist plastics formulated to resist harsh chemicals and survive environmental end use conditions such as sterilisation. However, the properties that allow these materials to withstand such conditions can also make them difficult to bond with adhesives. Here Kevin Brownsill, our Head of Technical: Learning and Development, shares guidance […]

Read More

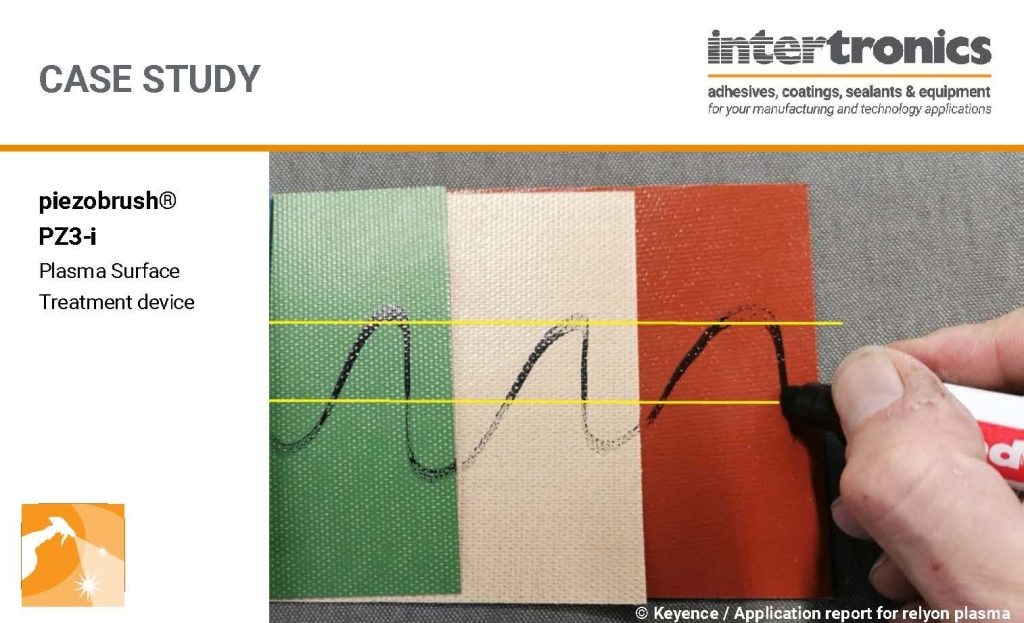

Case study: achieving reliable printing onto PTFE with plasma pre-treatment

Due to PTFE’s extremely low surface energy, it is difficult for materials to wet, and almost no materials or adhesives readily adhere to it. The commonly known brand name of PTFE-based composition is Teflon – yes, the non-stick stuff. However, plasma can be applied to alter the chemical groups on the surface, increase wettability and […]

Read More

Seminar: Improving Adhesion and Bond Quality with Plasma Surface Treatment

We’re delivering a free seminar at the upcoming Engineering Solutions Live show, held on the 23rd of March, entitled Improving Adhesion and Bond Quality with Plasma Surface Treatment. Cold plasma treatment can quickly activate and functionalise the surfaces of many difficult-to-bond substrates, including metals and plastics, whilst removing organic contaminants. This process improves the wetting […]

Read More

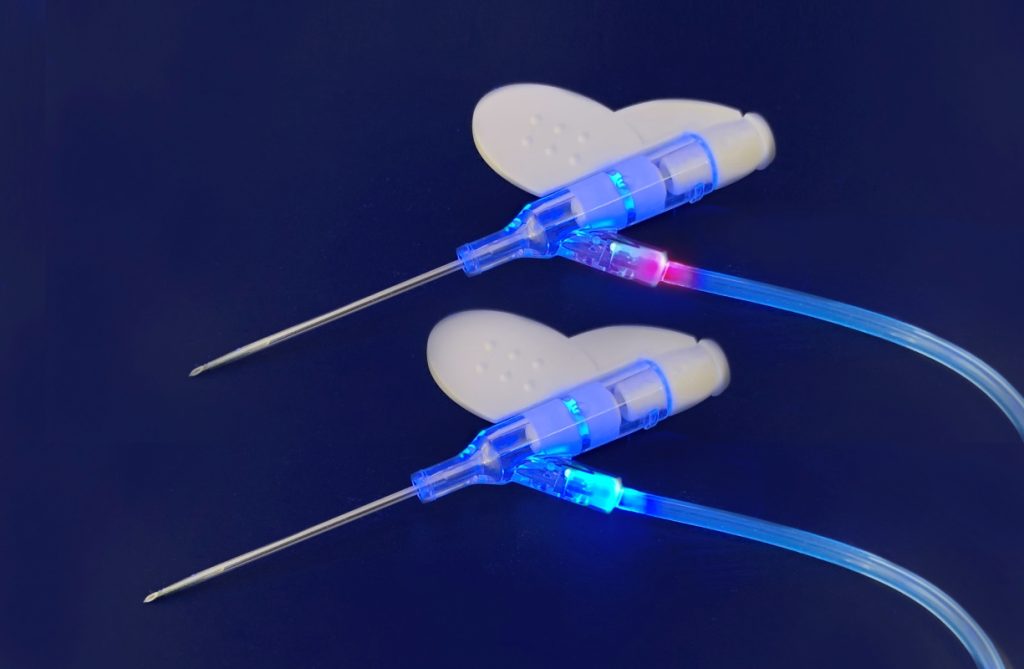

New plasma surface treatment module attachments expand applications

The most hard-to-bond substrates and awkward areas are now treatable with low temperature, plasma surface treatment. Two new modules, released by Relyon Plasma for their popular PiezoBrush PZ3 and PiezoBrush PZ3-i plasma systems, expand the applications which can benefit from activating, functionalising, and cleaning to increase wetting and improve adhesion. Needle Nozzle Cleaning and […]

Read More

Case study: improving overmoulding adhesion with plasma treatment

Founded in 2020, Wavecon specialises in cable solutions for subsea assemblies, offering a range of options from the supply of replacement cable harnesses and wired assemblies, through to fully designed and manufactured bespoke assemblies for specific applications. From the outset, the company decided to build an end-to-end manufacturing process, using high quality equipment, machinery and […]

Read More

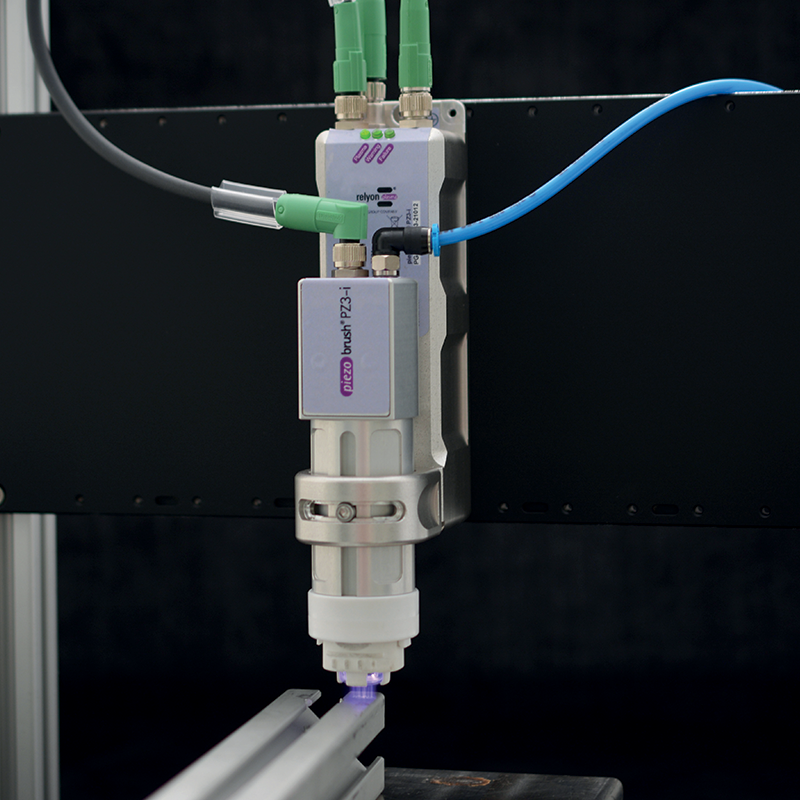

Plasma surface treatment – simple to automate

Providing you with an easy and affordable way to automate plasma surface treatment, the Relyon Plasma PiezoBrush PZ3-i allows simple integration into semi-automated or automated production lines whilst giving you full control over all process variables ─ positioning, power, time, and input gas pressure ─ for a repeatable, controllable, and recordable process. The PiezoBrush PZ3-i is […]

Read More

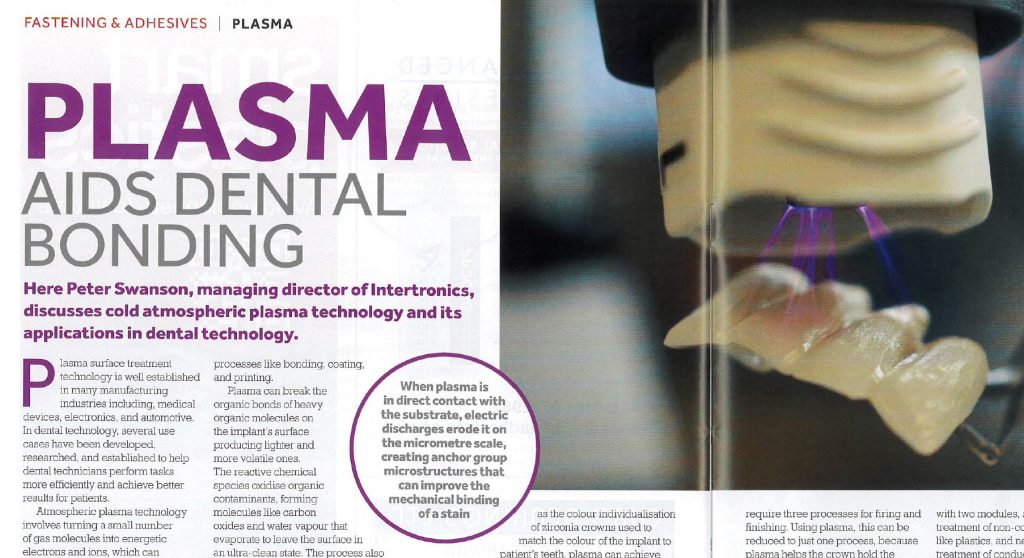

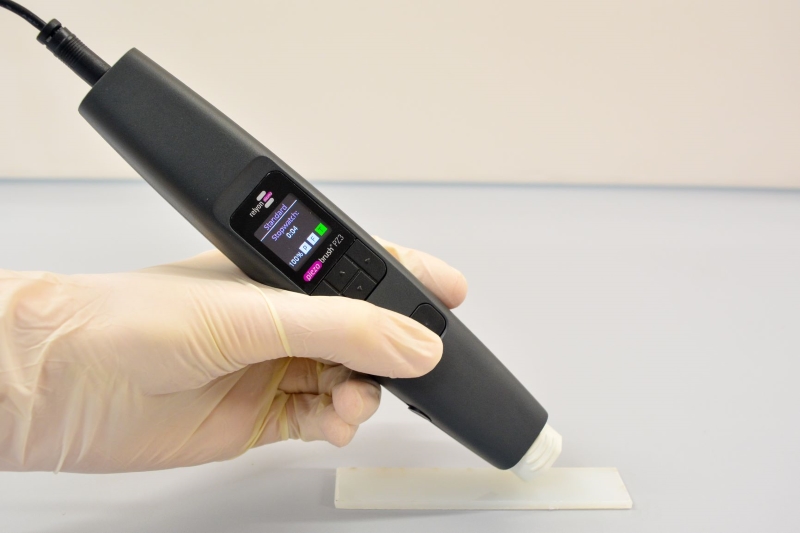

Article: plasma aids dental bonding

Eureka is a very highly regarded engineering magazine, so we were excited to see a two-page spread in the latest issue given over to our article Plasma Aids Dental Bonding. See page 32 to read how cold atmospheric plasma technology delivers benefits in dental labs. It features the PiezoBrush PZ3, the world’s smallest, highly effective […]

Read More

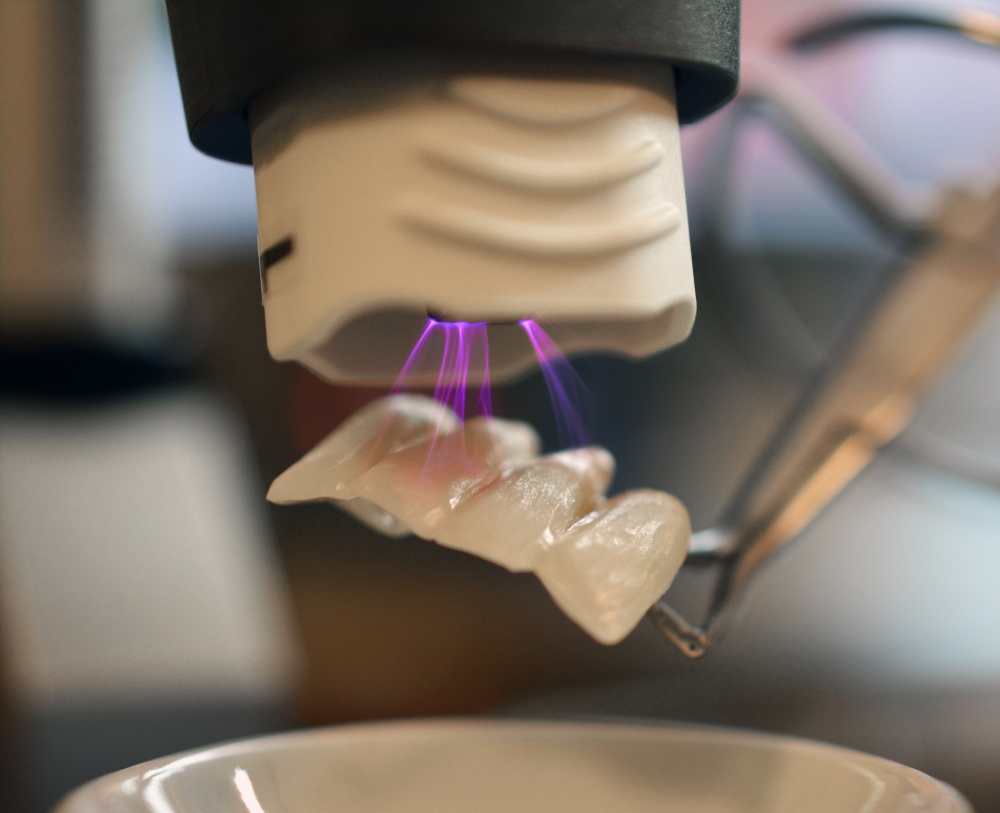

Plasma surface treatment in dental applications offers efficiency and better results

Plasma surface treatment technology is well established in many manufacturing industries including medical devices, electronics, and automotive. In dental technology, several use cases have been developed, researched, and established to help dental technicians perform tasks more efficiently and achieve better results for patients. Plasma can initiate several physical and chemical processes that both clean and […]

Read More

Case study: bonding 3D printed parts

3D printers usually print relatively small stuff – certainly less than 1 meter in any dimension. Our own 3D printer’s largest build dimension is 320mm, and that is fairly common. There are exceptions, of course – these days you can 3D print a two-story house. But for most applications, if you need to make a […]

Read More

Article: Cold plasma in electronics industry

The latest September 2020 issue of Global SMT & Packaging (The Global Assembly Journal for SMT & Advanced Packaging Professionals) contains an article from us entitled Cold Plasma in Electronics Industry. Adhesion plays a decisive role for product quality and process stability in many areas of the electronics industry. These include bonding and marking of […]

Read More

World’s smallest, highly effective handheld plasma treatment device

The PiezoBrush PZ3 Handheld Plasma Surface Treatment Device from Relyon Plasma is suitable for use in manual or semi-automated production, new product development, and in research and development settings such as a laboratories. It is simple, safe and intuitive. With a maximum power consumption of 18W, its unique Piezoelectric Direct Discharge (PDD®) technology is used […]

Read More

Three effective applications of plasma for glass surface pre-treatment

Plasma contains highly reactive species including electrons, ions and free radicals. Application of plasma to glass can make it hydrophilic, increase its surface energy and improve wettability, so that inks, paints or adhesives can wet better. In addition, it can remove organic, inorganic and microbial surface contaminants that form due to exposure to air. It […]

Read More

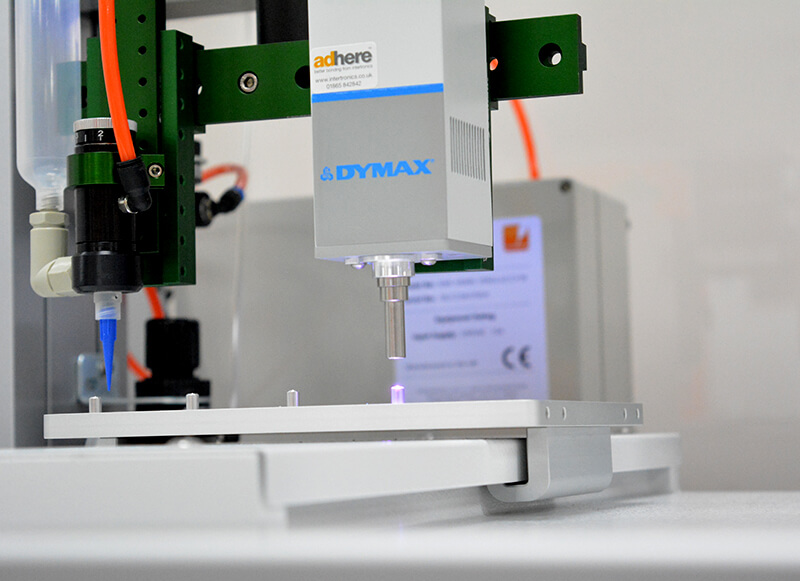

Integrating dispensing, curing and surface preparation equipment

We have a wide experience of integrating dispensing, curing and surface preparation equipment with our robots. Combining one or more of these processes onto one platform can deliver production efficiency and productivity – often at realistic cost which can payback very quickly. This two minute video explains the benefits we have delivered to customers over […]

Read More

Adhesion ’19 Conference to feature paper from Relyon Plasma

Corinna Little, from our partner Relyon Plasma GmbH, will be presenting her paper on “Enhancing the bonding properties of pressure-sensitive adhesives on white goods by means of atmospheric plasma treatment” at the Adhesion ’19 Conference, a symposium on the science and technology of adhesion and adhesives. Her synopsis is as follows: Atmospheric-pressure plasma can enhance […]

Read More

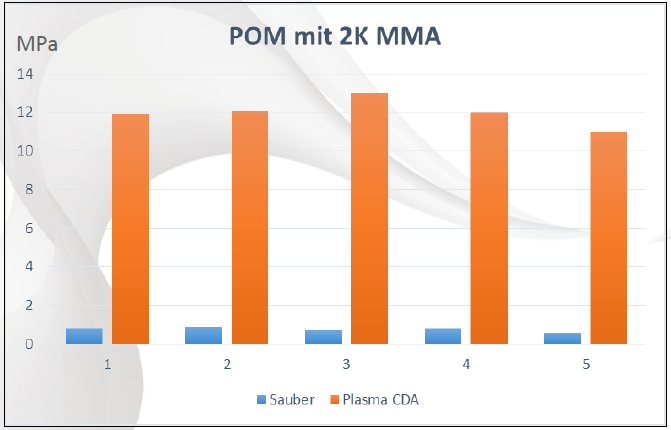

How to bond POM or acetal plastic

Polyoxymethylene (POM) is a high density thermoplastic, also called acetal or polyacetal. Brand names include Delrin, Ultraform and Hostaform*. It is often used as an engineering grade plastic, especially for precision parts. POM is extremely solid, hard and stiff in a wide temperature range. It maintains its high ductility up to -40°C and has excellent […]

Read More

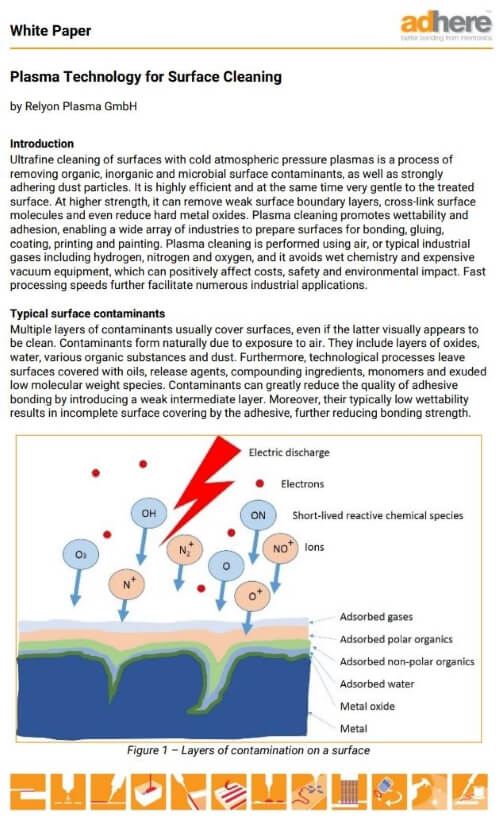

White Paper: Plasma Technology for Surface Cleaning

Whilst our customers typically use plasma technology to improve their bonding, another use of plasma is ultrafine surface cleaning. Relyon Plasma, our sales partner, has produced an in-depth explanation of how plasma technology can clean surfaces, which we have added to our library of technical resources. You can read the White Paper on Plasma Technology […]

Read More

Time to bond with plasma technology

The January/February 2019 issue of Plastic News Europe features our article Time to bond with plasma technology. The piece concludes: “Plasma is not limited to natural phenomena like stars and the Northern Lights. Manufacturers should consider plasma treatment if they are frequently faced with difficult-to-bond substrates. The benefits can be particularly compelling for medical device, […]

Read More

Everything you need to know about air dusters… but were afraid to ask

Our partners Techspray have a new blog post about Dusters – also called “air duster”, “canned air”, “compressed air”, and “dusting gas”, they are used to provide a pressurised blast, knocking loose dust and dirt. Think of them as a portable replacement for an air compressor line. They can be used to blow out biscuit […]

Read More

Factors for consideration when bonding composite materials

Composites continue to be the subject of rapid advancement in terms of formulation, production and types of applications. Incorporating composites in your assemblies requires adhesives that contribute to the highest possible performance and reliability, exploit their qualities of strength and light weight and meet the demanding conditions of the automotive, defence, aerospace, marine, medical, electronics/electrical, […]

Read More

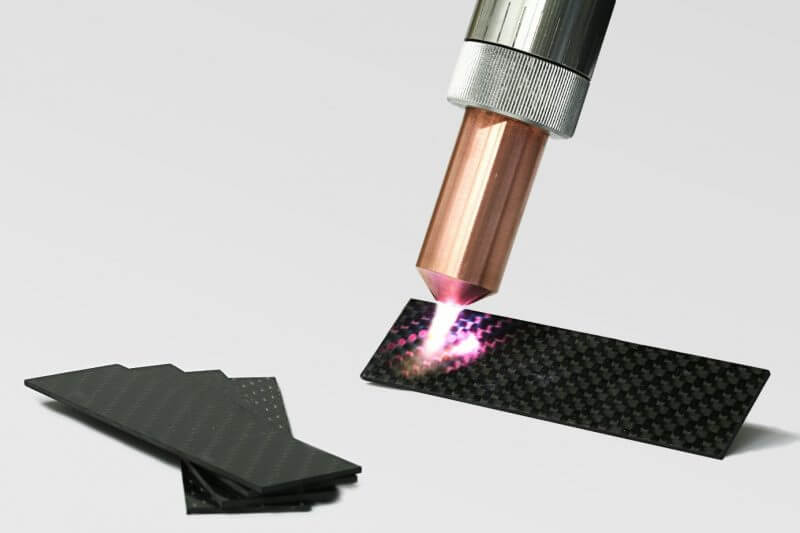

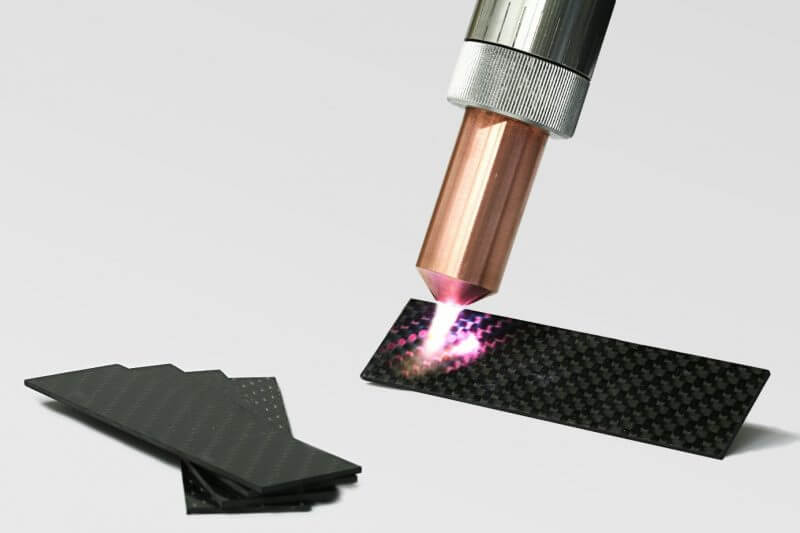

Plasma surface treatment for bonding composites

The bonding with adhesives of plastics to metals is an application which is growing. A typical example is the bonding of composite materials (carbon fiber, CFRP) and aluminium (Al) materials in the automotive sector. Various adhesives can meet the structural requirements of the bond. However, a polymer matrix of carbon fiber reinforced materials can have […]

Read More

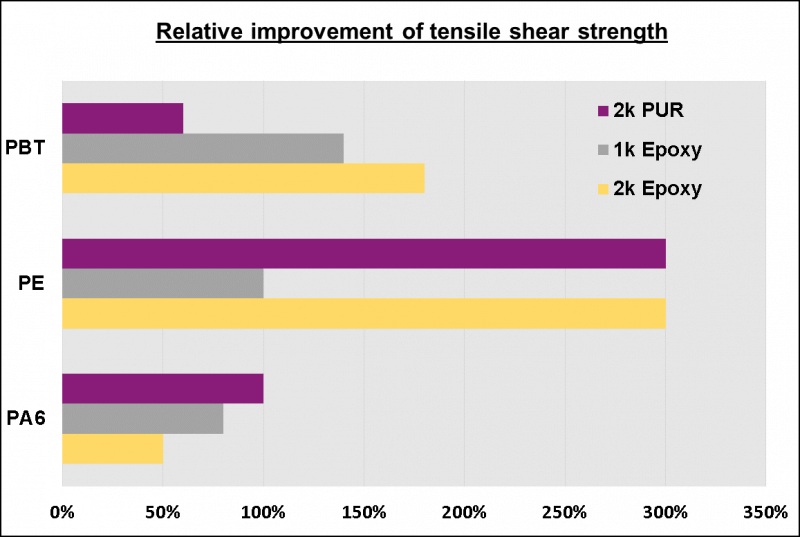

Plasma surface functionalisation for improved structural bonding of plastics

Thinking about improved structural bonding of plastics? Plastics are usually characterised by inert surfaces with surface energies between 20 and 40 mN/m. In order to wet a surface, however, the surface energy of the polymer must exceed the one of the paint, ink or the adhesive. This condition can be achieved through a plasma treatment […]

Read More

Industrial cleaning wipes: order today and receive them tomorrow!

“Our technicians wanted me to source your wipes, as they are better than any wipes we have been using.” “The sample IPA wipes have been approved by management – they’re over the moon with the quality and performance.” We are delighted with how happy our customers are with our cleaning wipes. Available from stock for […]

Read More

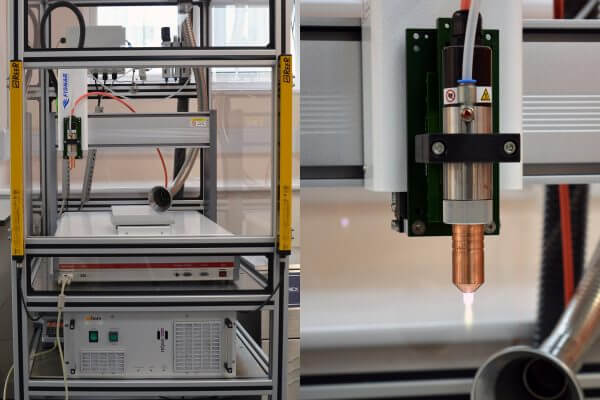

Automated plasma surface treatment package available

Visitors to the our Technology Centre near Oxford will have noticed the enclosure containing a robot-mounted Relyon PB3 Plasmabrush plasma surface treatment system. We have created an integrated plasma surface treatment package which is being used for customer demonstrations and evaluations, and is available for purchase as a turnkey automated workstation. The Relyon PB3 Plasmabrush plasma treatment […]

Read More

Challenging surface activation applications met by the PiezoBrush PZ2

The Relyon Plasma PiezoBrush® PZ2 has nozzle attachment options for surface activation across a wide range of applications. Treatment of metals, and smaller and more precise applications are now possible. The use of a variety of special gases enhance the possibilities of PDD (Piezoelectric Direct Discharge) on challenging substrates. Based on the direct, electric discharge at […]

Read More

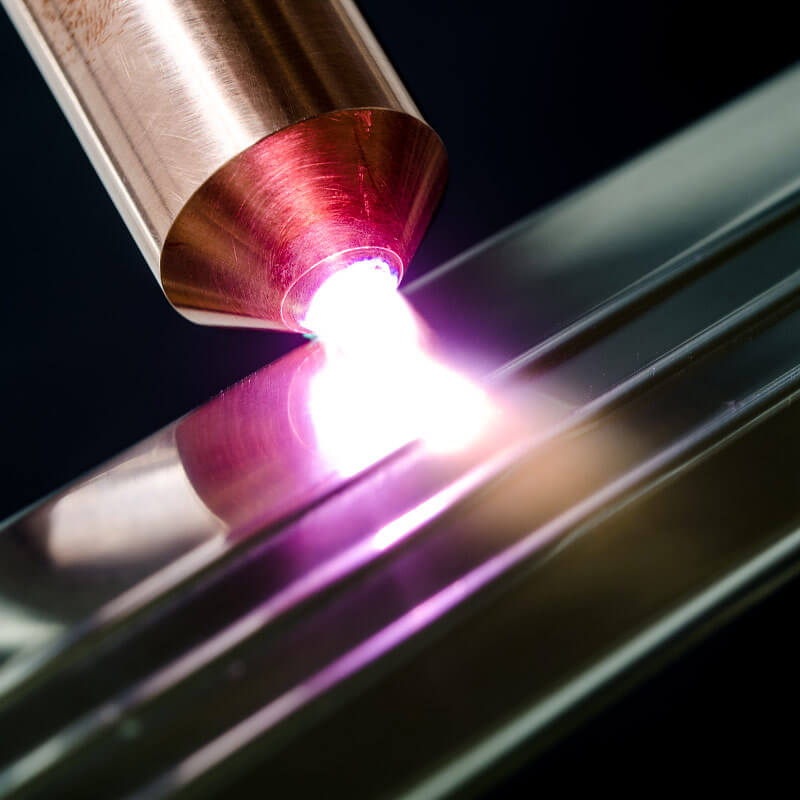

Automated plasma surface treatment on demonstration

If you’ve visited our Technology Centre here in Kidlington lately, you will have noticed the enclosure containing a robot-mounted Relyon PB3 Plasmabrush plasma surface treatment system. Relyon plasma surface treatment products improve adhesion and wetting of surfaces which are otherwise difficult to bond, print on, coat or laminate. Atmospheric plasma surface treatment is both […]

Read More

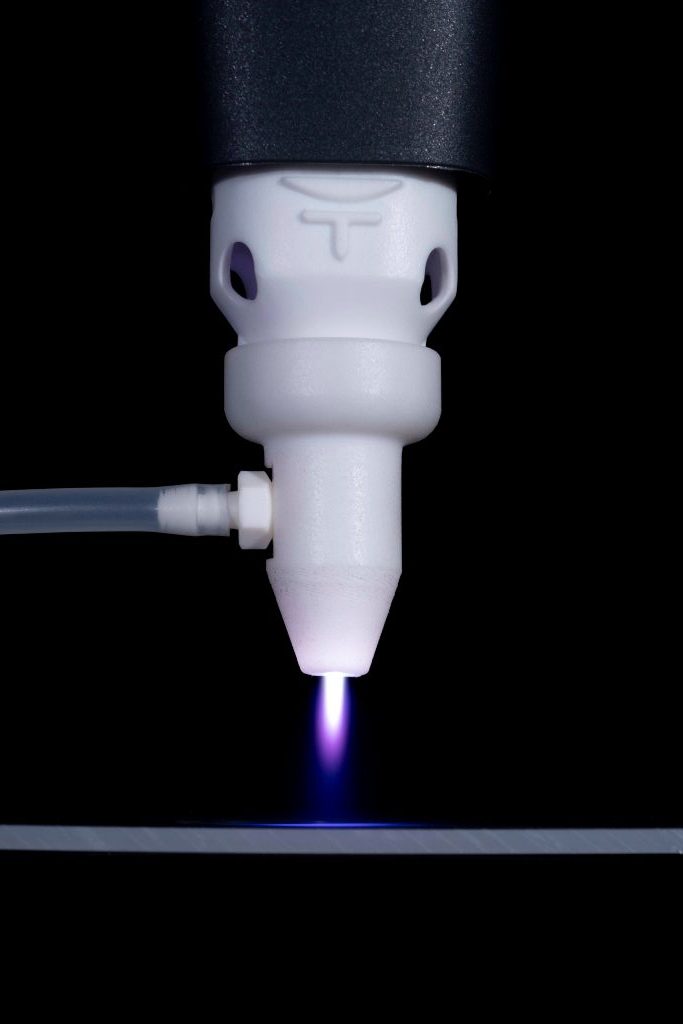

Relyon Plasma PB3 Plasmabrush for plasma cleaning and surface activation

The Relyon Plasma PB3 Plasmabrush offers convenient, high speed, high performance atmospheric plasma cleaning and surface activation. The PB3 Plasmabrush is a nozzle-type plasma generator which is particularly compact and offers long-term stability. Proprietary Pulsed Atmospheric Arc Technology uses a unipolar pulsed high voltage source and a vortex flow in the nozzle which delivers uniform […]

Read More

Relyon Plasma surface treatment now available in the UK

We are pleased to announce a new sales partnership with plasma treatment company Relyon Plasma GmbH which brings their advanced technology within reach of UK manufacturers. Plasma surface treatment can be a very effective way to activate a surface in order to prepare it for bonding or printing, enabling improved wetting and adhesion. We are […]

Read More