Category: technical resource

adhere academy: how to prepare two-part cartridges for dispensing

Many adhesives, sealants, and potting materials are packaged in two-part side-by-side cartridges, which are convenient for material application on the production line or in the field. Cartridges don’t require you to measure out materials in the correct ratio, and by adding the manufacturer’s recommended static mixing nozzle, fully mixed and homogeneous material can be dispensed […]

Read More

Kevin Brownsill promotes knowledge of adhesives technology to UK manufacturers

Kevin’s been at Intertronics for 15 years, having started in Sales and progressed into Sales and Technical management. Over this time, he’s developed a deep understanding of this specialised area, as well as built strong relationships with customers, and has taken responsibility for our Technology Centre. To help grow understanding of the selection and processing […]

Read More

25 top tips for optimally dispensing your materials

If your process involves dispensing materials like adhesives, inks, coatings, sealants, lacquers, paint, lubricants, or anything similar, our 25 Top Tips for Dispensing is worth a read – a collection of handy tips covering many dispensing applications which can help you fine-tune what you’re doing for optimal results. Covering dispensing pressures to types of dispensing […]

Read More

White Paper: Sustainability benefits of LED UV curing

LED UV curing lamps are swiftly gaining popularity as a replacement for mercury arc lamps. Their rise in use reflects their process benefits, such as instant on/off and consistent intensity for thousands of hours. In addition to these, there are environmental advantages at play, such as reduced energy consumption, decreasing a business’ carbon footprint, and […]

Read More

White Paper: Adhesive considerations at the design stage

When it comes to the design and development of new products, and choosing an adhesive to bond them together, an adhesive supplier often finds themselves as the last port of call. This approach can leave you in a position where your list of requirements severely limits the adhesives suitable for your application. Bondline design, substrate […]

Read More

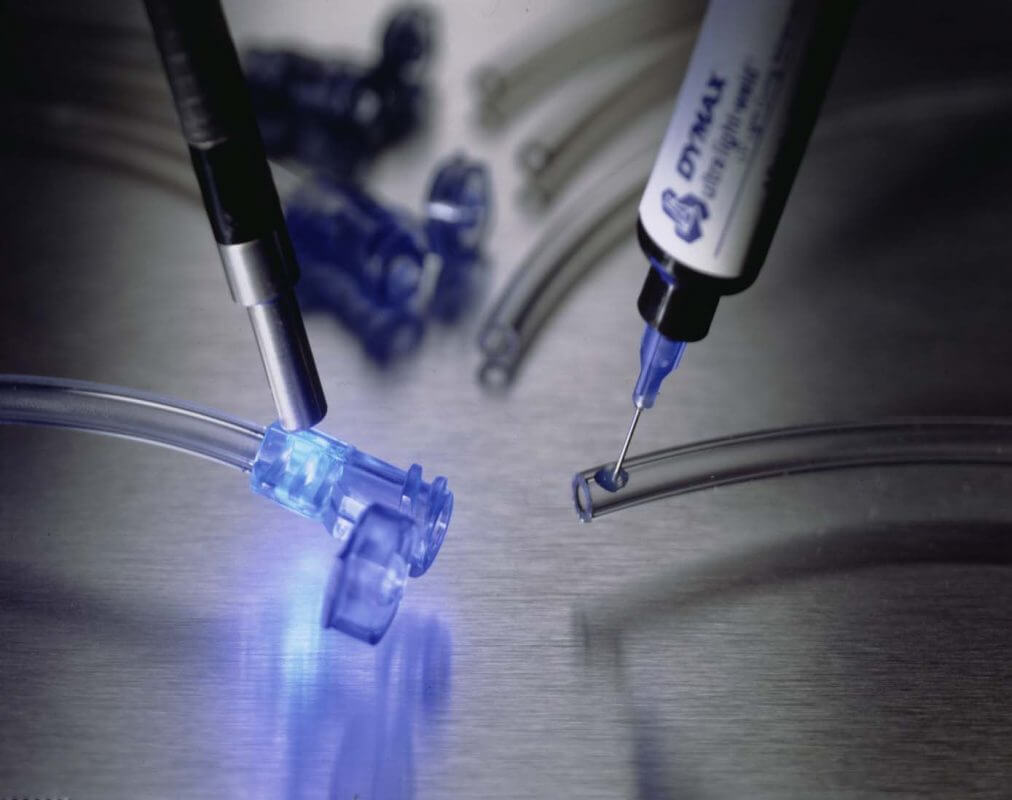

White Paper: Designing in light curing adhesives – a holistic approach to adhesives in medical device assembly

UV curable adhesives grant significant manufacturing productivity benefits, curing in seconds, “on-demand” when exposed to UV light. With grades certified to ISO 10993 and USP Class VI stands available, they are also well-matched to the manufacture of medical devices. To fully realise the potential that this adhesive technology can bring, it is necessary to take […]

Read More

Get hands-on with trials and demos for adhesives and equipment

For years, we have helped our customers develop their production through evaluation and specification of new assembly materials and equipment at our Technology Centre, located in Kidlington, Oxfordshire. Filled to the brim with mixing, surface treatment, dispensing, robots and curing equipment, along with a warehouse full of materials, our Centre allows us to help you […]

Read More

Adhesive selection: A race against the clock?

There are a few considerations when specifying an adhesive for your application, such as how well it bonds your substrates and if it can meet the functional needs of your application. One other important piece of the puzzle are the time-based factors which dictate how materials can be processed. Our technical white paper Adhesive selection: a race against the clock? walks you through the various time-sensitive factors at […]

Read More

Achieving a fast, repeatable mixing process without air bubbles

Transforming multiple parts of liquids, pastes and powders into homogeneous, ready-to-use materials which are air and bubble free – that’s what our THINKY planetary mixers do. Our newly released Technical Bulletin Achieving a fast, repeatable mixing process without air bubbles summarises the capabilities of these machines: Planetary mixing Degassing Mixing under vacuum Which capabilities you […]

Read More

White Paper: Nailing your UV curing adhesive process

Process speed and simplicity are just two of the many productivity benefits that light curing adhesives and coatings bring to the table. If this is a new process for you, or you are setting up production on a new product, then you will want to figure out how to get it working reliably and repeatably. […]

Read More

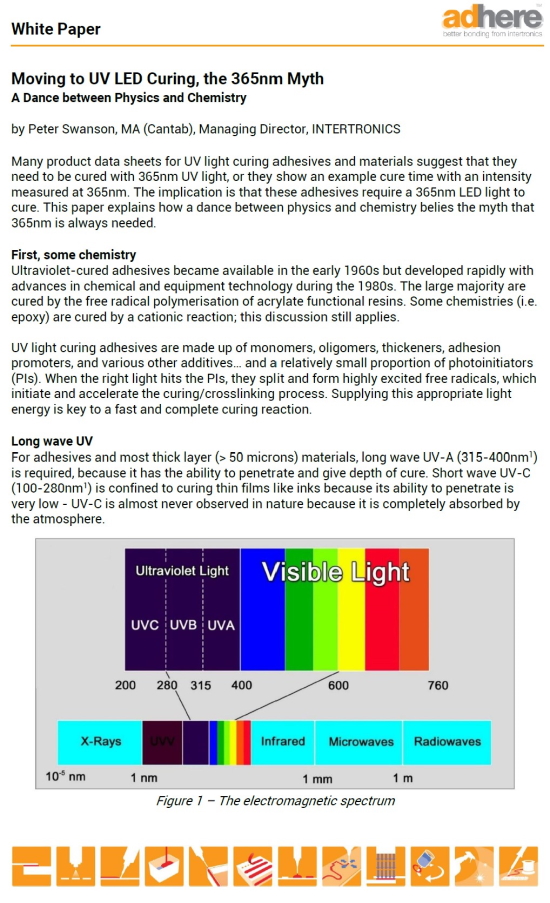

White Paper: Moving to UV LED curing, the 365nm myth – a dance between physics and chemistry

Our latest White Paper, entitled Moving to UV LED Curing, the 365nm Myth – A Dance between Physics and Chemistry, discussed the assumptions around using UV LEDs to cure adhesives, coatings, sealants, encapsulants and temporary masking materials. Despite some hints on product data sheets, 365nm may very well not be the best wavelength to pick […]

Read More

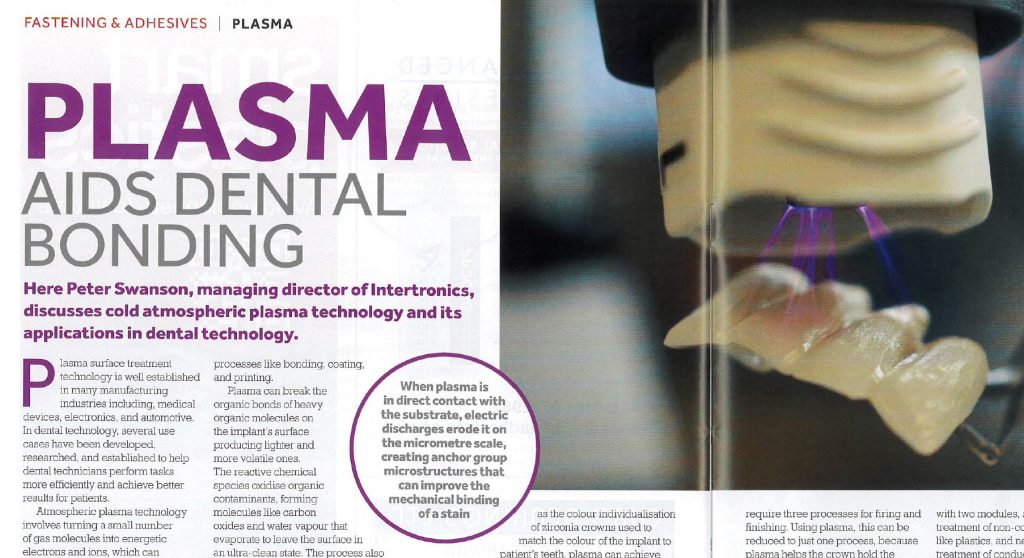

Article: plasma aids dental bonding

Eureka is a very highly regarded engineering magazine, so we were excited to see a two-page spread in the latest issue given over to our article Plasma Aids Dental Bonding. See page 32 to read how cold atmospheric plasma technology delivers benefits in dental labs. It features the PiezoBrush PZ3, the world’s smallest, highly effective […]

Read More

White Paper: Adhesive selection: a race against the clock?

One of our recently published White Papers discusses time-based considerations when specifying adhesives for any application. Not only are you looking for an adhesive that bonds well to your required substrates, but one which also meets the functional requirements of its application. In addition to these, there are also time-based considerations to factor in. Read […]

Read More

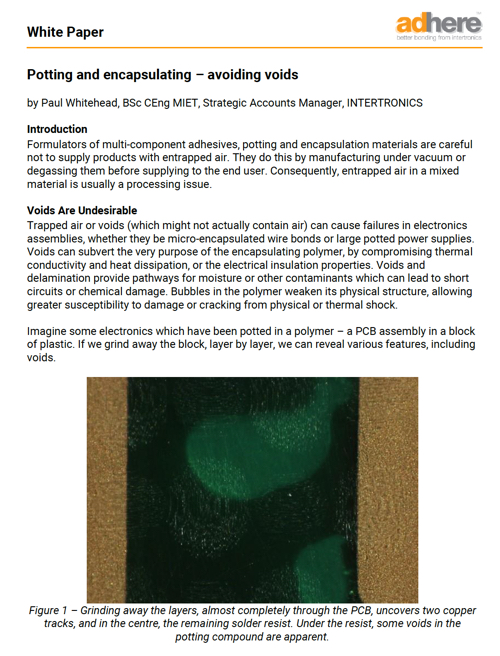

Cover star – avoiding potting voids article

The latest issue of Global SMT & Packaging features our White Paper on the cover. Potting and encapsulating – avoiding voids was written by Paul Whitehead, our Strategic Accounts Manager. It discusses potting voids – what are they, why they are bad, and how to prevent them happening. Click through to read this issue, with […]

Read More

White Paper: Potting and encapsulating – avoiding voids

Our latest White Paper tackles the issue of voids in potting compounds and encapsulation. Potting and encapsulating – avoiding voids was written by Paul Whitehead, our Strategic Accounts Manager. It discusses voids – what are they, why they are bad, and how to prevent them happening. If you are involved with electronics potting or encapsulation, […]

Read More

White Paper: UV light and moisture curable electronics encapsulants

Encapsulants are often required to protect electronic components against moisture, chemicals, and rapid and extreme temperature changes while providing mechanical support and electrical insulation. Light-curable encapsulating compounds can provide significant benefits over conventional technologies, including very fast curing, lower operating costs and increased productivity driven by lower labour requirements, space savings, lower energy demand, and […]

Read More

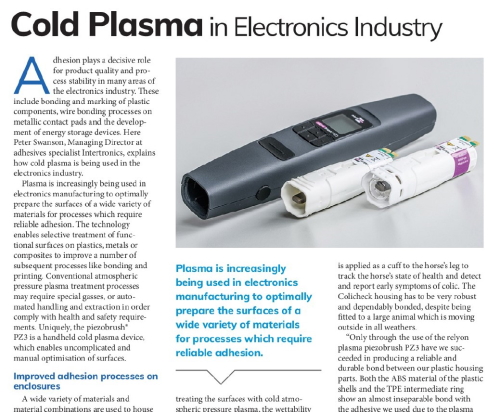

Article: Cold plasma in electronics industry

The latest September 2020 issue of Global SMT & Packaging (The Global Assembly Journal for SMT & Advanced Packaging Professionals) contains an article from us entitled Cold Plasma in Electronics Industry. Adhesion plays a decisive role for product quality and process stability in many areas of the electronics industry. These include bonding and marking of […]

Read More

White Paper: Are Cyanoacrylate Adhesives Structural?

This new White Paper, entitled Are cyanoacrylate adhesives structural?, looks at the role of cyanoacrylate adhesives in load-bearing, structural applications. It discusses a new development which repositions this chemistry in the hierarchy of adhesives. Click on the image to read the full article. We have this White Paper and many other technical resources, including articles, […]

Read More

How do I validate my UV curing process?

If you are establishing a new process involving the UV light curing of an adhesive or another light curing material, we can highly recommend these resources. All are from our partners, Dymax. First, a couple of articles entitled Validating a UV Flood Curing Process and Validating a UV Spot Curing Process. Secondly, a couple of […]

Read More

Getting your trials done with a live video meeting

In our determination not to let the pandemic keep us down, we have been pursuing further methods to help our customers push their businesses forward. We have always provided a service for helping you evaluate materials and equipment by providing testing in our Technology Centre. Often the results are provided to you in a written […]

Read More

Article: time-based adhesive selection

The latest issue of FAST magazine comes complete with this article about time-based adhesive selection. Factors like shelf life, working life and cure time may all be relevant to your production. It only takes five minutes to read it.

Read More

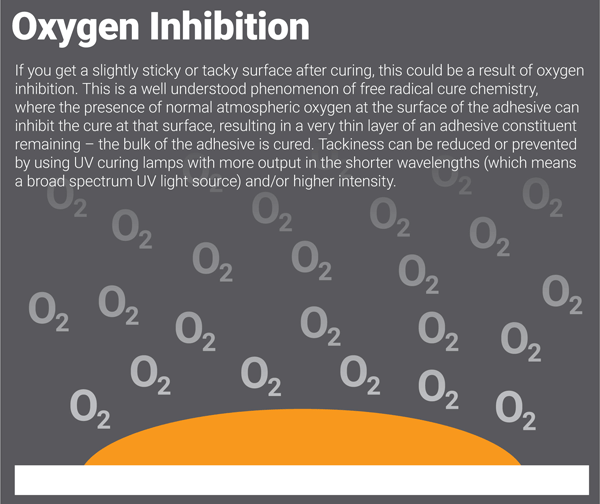

Oxygen inhibition: achieving a tack-free cure with UV adhesives and coatings

Sometimes, cured UV adhesives or coatings have a tacky or sticky surface, even after they are exposed to the correct amount of UV light to achieve full cure. If the surface of the adhesive is exposed to atmospheric oxygen during the cure, the oxygen can penetrate into the very top layer and inhibit the polymerisation […]

Read More

Adhesives – keeping the finishing line in sight

The June 2019 issue of Industrial Technology magazine contains a great piece from our Technical Manager, Kevin Cook, entitled Keeping the Finishing Line in Sight. The Sydney Opera House turned out to be one of the most disastrous construction projects in history, running vastly over time and budget. Designed by Danish architect Jorn Utzon, the […]

Read More

Adhesive consideration – designing with production in mind

The April 2019 issue of Design Products & Applications magazine is now available, and it contains a piece from our Technical Manager, Kevin Cook, entitled Adhesive Consideration – Designing with Production in Mind. In 2018, the New South Wales Government faced embarrassment after ordering $2 billion worth of new trains that were too wide for […]

Read More

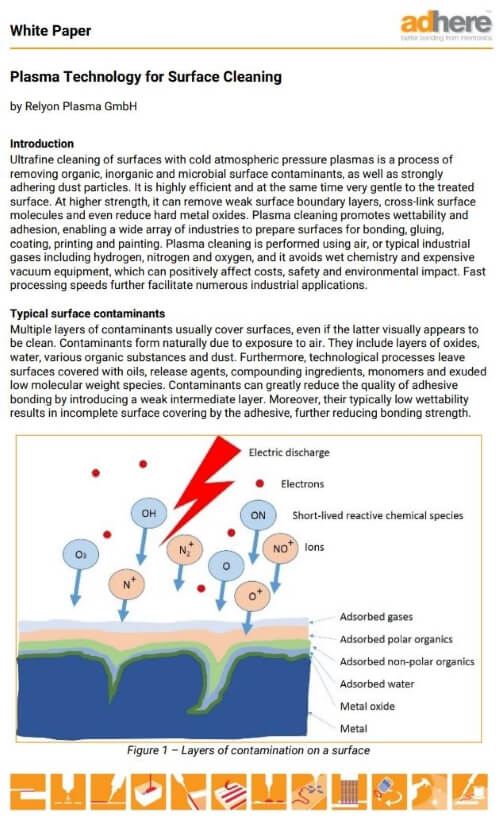

White Paper: Plasma Technology for Surface Cleaning

Whilst our customers typically use plasma technology to improve their bonding, another use of plasma is ultrafine surface cleaning. Relyon Plasma, our sales partner, has produced an in-depth explanation of how plasma technology can clean surfaces, which we have added to our library of technical resources. You can read the White Paper on Plasma Technology […]

Read More

adhere academy: shelf life of adhesives

We wrote about shelf life in this adhere academy blog post pot life v shelf life v working life – part 1. Our partners at Dymax have written a blog post entitled 5 Questions to Help You Understand Shelf Life with answers to these questions: How is the shelf life of a product determined? Where do […]

Read More

Automated dispensing across industry

Another excellent issue of FAST magazine has recently crossed our desk; editor Brian Wall continues to pack it with great content about fastening & assembly solutions and technology. It includes an article from us entitled Automated dispensing across industry – the applications and benefits of automated adhesive and sealant dispensing are manifold, with manufacturers reaping […]

Read More

Article: tips and hints for UV curing

We were very pleased to see some extensive coverage of some of our tips and hints for UV curing in the latest issue of FAST (Fastening & Assembly Solutions And Technology) Magazine – the UK’s only journal dedicated 100% to the subject of fastening, bonding and assembly in manufacturing applications. We recommend that you subscribe. […]

Read More

White Paper – dispensing quality measurement

The flowplus16 is an inline fluid sensor for monitoring the pressure of adhesive, coating or other material being dispensed or dosed. By understanding changes in pressure of material flow, consistency or other quality issues (like blockages or air inclusions) can be identified in order to produce consistent dosing results and dispensing quality. In this White […]

Read More