Category: adhere academy

adhere academy: storage and packaging of two-part structural adhesives

An adhesive’s data sheet will detail its storage requirements, but most two-part structural adhesives will last their whole specified shelf life if stored at room temperature in a cool dark place. There are some differences between the chemistries that may impact how they are packaged and stored. For example, both components of a two-part polyurethane […]

Read More

adhere academy: handling and processing two-part structural adhesives

It’s common for structural adhesive chemistries like epoxies, polyurethanes (PUs), and methyl methacrylates (MMAs) to have been formulated as two component parts – known as “two-part”, or “2K” adhesives. The two components of these adhesives are generally categorised as the resin (or base) and the hardener (or activator). Mixing the two parts initiates a chemical […]

Read More

adhere academy: how to prepare two-part cartridges for dispensing

Many adhesives, sealants, and potting materials are packaged in two-part side-by-side cartridges, which are convenient for material application on the production line or in the field. Cartridges don’t require you to measure out materials in the correct ratio, and by adding the manufacturer’s recommended static mixing nozzle, fully mixed and homogeneous material can be dispensed […]

Read More

What is the difference between an adhesive and a sealant?

Our customers often use adhesives and sealants in their products, in a wide variety of applications. They can be seen as quite similar materials, and indeed have overlapping uses. Some adhesives are also used as a sealant; some sealants are also used as an adhesive. We even sell products which are termed “adhesive sealants”. But […]

Read More

adhere academy: adhesive and dispensing technology seminars for you

Having spent more than 30 years working with adhesives and protective materials in technology manufacturing, and with experience of thousands of applications, we have a wealth of knowledge to we want to share. In a bid to help grow your adhesives, dispensing, and curing technology knowledge, we are offering seminars which share our insights, helping […]

Read More

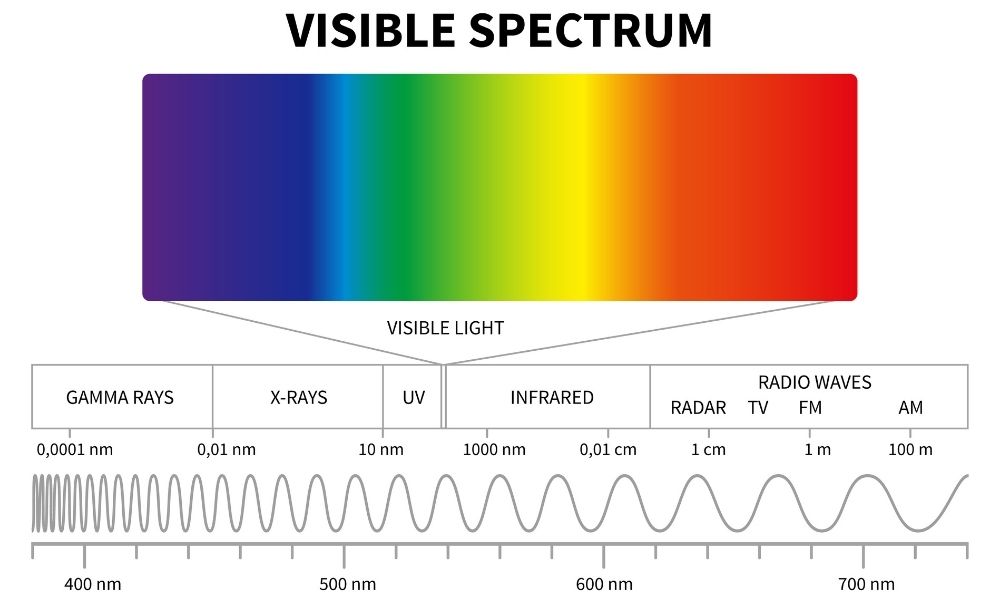

adhere academy: can you see UV light?

UV or ultraviolet light is part of the spectrum of electromagnetic radiation, which also includes radio waves, microwaves, infrared radiation, X-rays, gamma rays – and of course, visible light. These different types of radiation are defined by their wavelengths or frequencies. Radio waves have the longest wavelengths, and gamma rays the shortest. By definition, what […]

Read More

UV curing intensity – check your distance

A fundamental element of achieving the correct dose of UV light is ensuring the intensity of your UV curing lamp is understood. UV curing intensity as noted on a lamp’s data sheet is typically measured from a particular distance, so if your lamp is not set up to the same distance as the data sheet […]

Read More

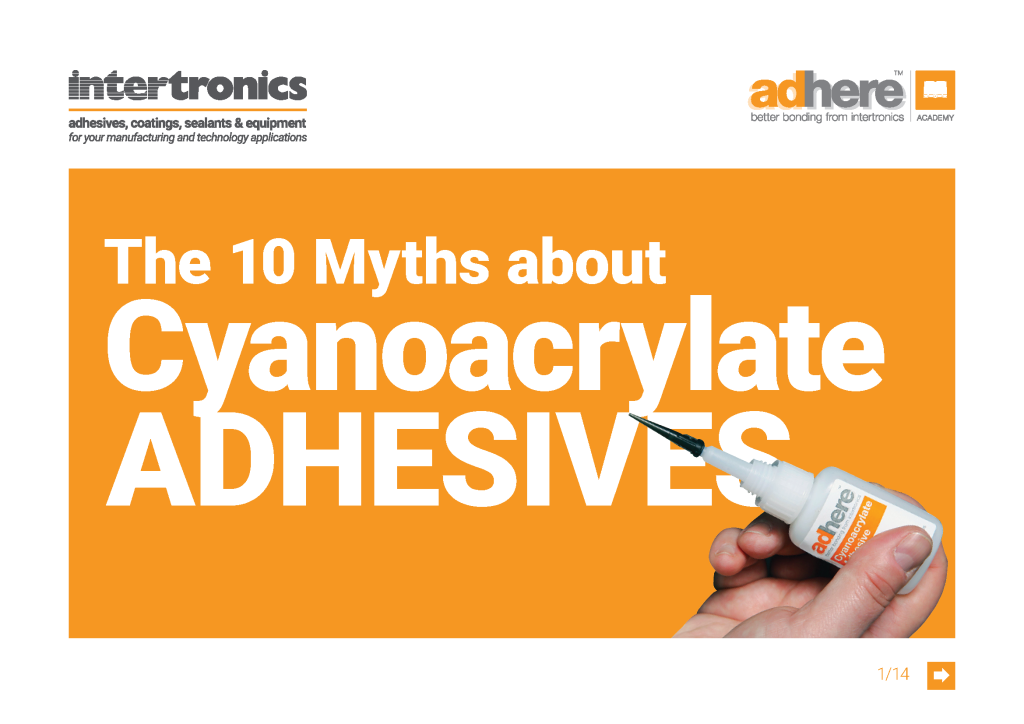

Dispelling 10 popular myths about cyanoacrylate adhesives

Cyanoacrylate adhesives (CAs) — also known as “superglue” or instant adhesives — are a popular adhesive choice for many applications, both industrially and domestically. Curing at room temperature in seconds, they provide excellent bond strength on a wide range of similar and dissimilar substrates including metals, plastics, elastomers, ceramics, and porous materials. Achieving these throughput […]

Read More

adhere academy: what does hygroscopic mean?

Hygroscopic materials attract and absorb humidity from the air. An example is the way granulated sugar gets lumpy in the sugar bowl or salt clumps in the salt shaker blocking the holes when in humid environments like a steamy kitchen. Lots of materials are hygroscopic, including paper, isopropyl alcohol (IPA), and plastics like ABS. Nylon […]

Read More

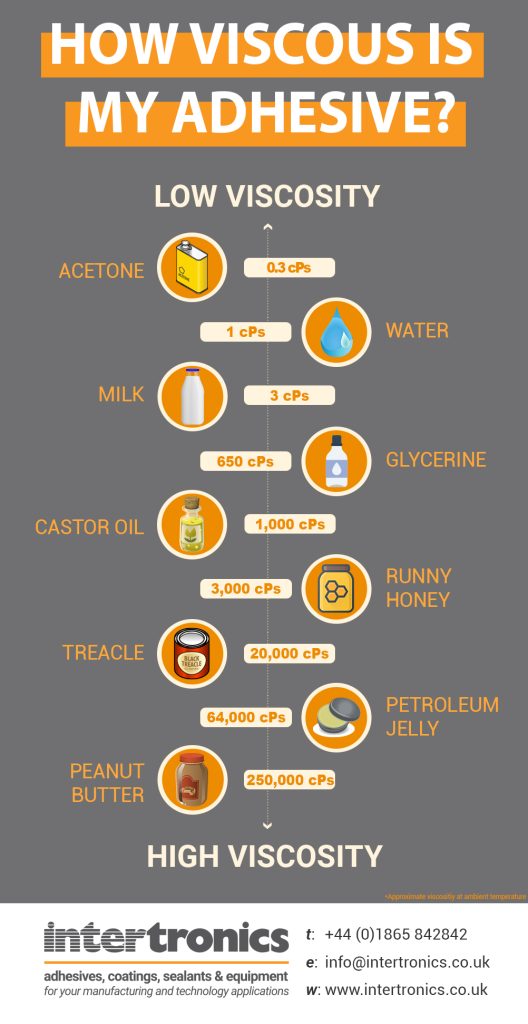

adhere academy: what is viscosity?

Viscosity is the resistance of a fluid to flow. This means that different fluids with different viscosities will flow at different rates under the same force. The higher a viscosity a fluid has, the harder you have to push it to move it. We call a higher viscosity fluid more viscous. You can see why […]

Read More

adhere academy: UV curing tips and tricks

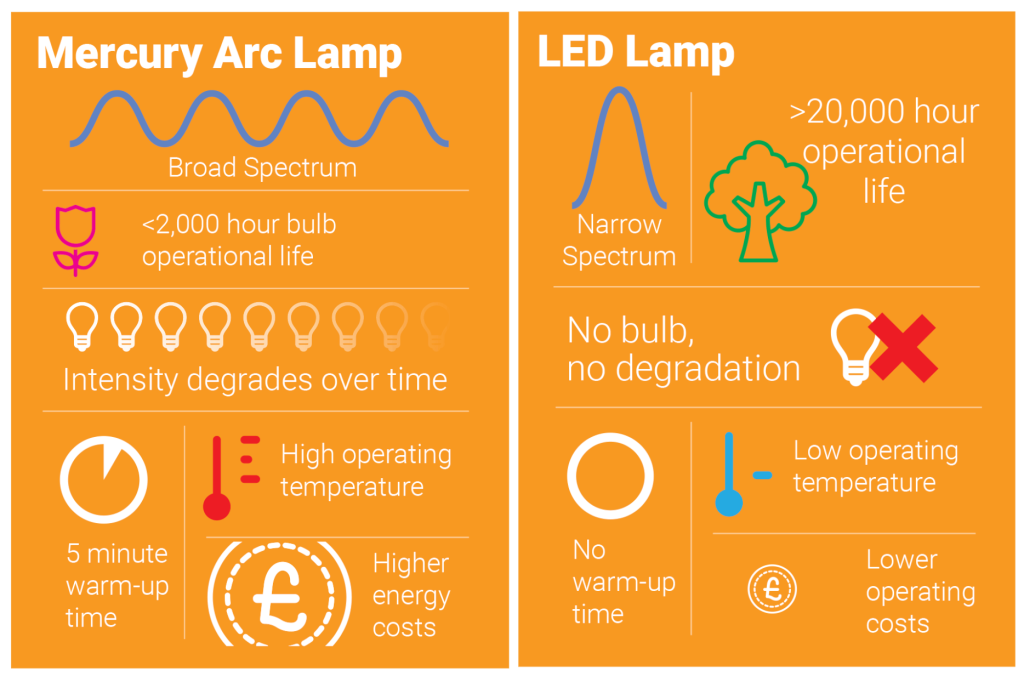

Bonding effectiveness, rapid cure time and process efficiencies have made light curing materials popular for manufacturers for assembly applications. Here, we share three tips for your UV curing processes. With a clear understanding of the UV curing process and the technology available, you can make informed choices and optimise your process. Broad vs narrow spectrum lamps The […]

Read More

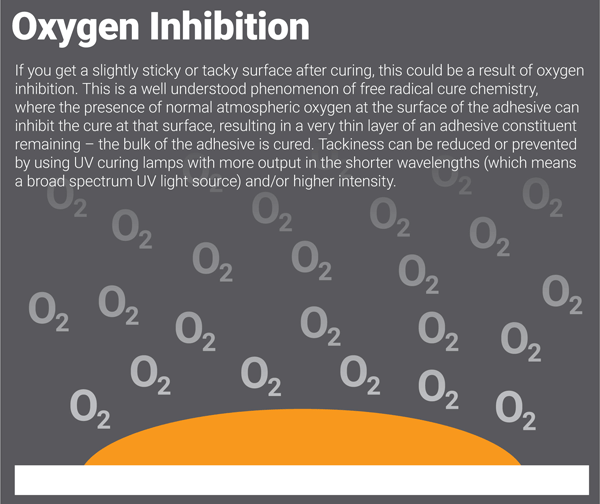

Oxygen inhibition: achieving a tack-free cure with UV adhesives and coatings

Sometimes, cured UV adhesives or coatings have a tacky or sticky surface, even after they are exposed to the correct amount of UV light to achieve full cure. If the surface of the adhesive is exposed to atmospheric oxygen during the cure, the oxygen can penetrate into the very top layer and inhibit the polymerisation […]

Read More

adhere academy: what is adhesive fixture time?

The fixture time for an adhesive (sometimes called the set time) is the shortest time required by the adhesive to develop handling strength such that substrates can be removed from fixtures, unclamped, or handled without stressing the bond – stress which might affect the ultimate bond strength. We can define handling strength as a (relatively) […]

Read More

adhere academy: shelf life of adhesives

We wrote about shelf life in this adhere academy blog post pot life v shelf life v working life – part 1. Our partners at Dymax have written a blog post entitled 5 Questions to Help You Understand Shelf Life with answers to these questions: How is the shelf life of a product determined? Where do […]

Read More

adhere academy: are RTV silicone sealants corrosive?

Yes, some are. It is good to understand this chemistry and the different types so that you can make sure you choose an appropriate RTV silicone sealant for your application. RTV silicone sealants are very useful products, because of their outstanding long term thermal resistance and stability (-50° to +180°C or more), long-lasting flexibility and […]

Read More

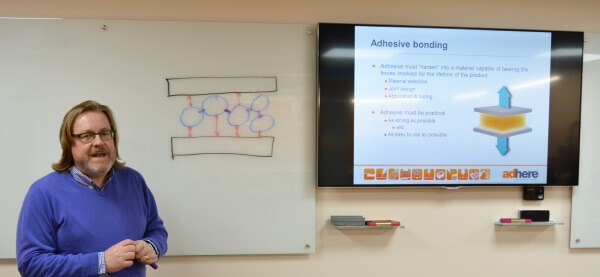

What is a structural adhesive?

A structural adhesive is an adhesive which “hardens” or cures into a material capable of holding two or more substrates together, bearing the forces involved for the lifetime of the product. It is often termed a “load-bearing” adhesive. The product may undergo shock, vibration, chemical exposure, temperature excursions or many other types of potentially weakening or […]

Read More

Choosing a Structural Adhesive: Free Seminar

Peter Swanson, our Managing Director, will be delivering a seminar titled ‘The Art and Science of Choosing a Structural Adhesive’ at FAST Live, held at the National Motorcycle Museum on May 10. The seminar, and the co-located exhibition, are free to attend. With an increasing number of structural adhesives on the market, this technical seminar […]

Read More

Technology seminars at your place

Our Managing Director Peter Swanson was delighted to be quoted in Brian Wall’s editorial in the latest issue of FAST (Fastening & Assembly Solutions And Technology) magazine. The context concerned the value of exhibitions and other conventions where industry meets: In an age where the Internet and digital technology have become so powerful in delivering […]

Read More

How to degas a syringe using a THINKY ARE-250 mixing and degassing machine

How to degas a syringe using a THINKY mixing and degassing machine is a visual guide to removing air from syringe packaged materials. Suitable for degassing materials from low to high viscosity the THINKY ARE-250 can also uniformly mix your compound, epoxy, adhesive, silicone, paste, powder or other material before being decanted into syringes and degassed ready […]

Read More

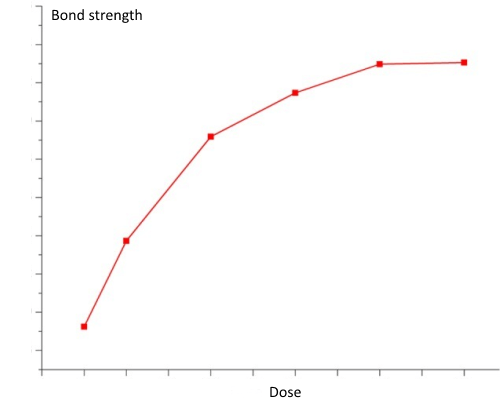

adhere academy: how much UV curing energy will I need?

In setting up a UV light curing process, the key to success is ensuring that the adhesive or other light curing material receives the correct dose or UV curing energy in order to cure as completely as possible. Dose is the total energy arriving at the surface per unit area and is made up of the […]

Read More

How much adhesive will I need?

We have added a new Technical Bulletin to our Technical Resources to help answer the commonly asked question: “How much adhesive will I need?“. The Technical Bulletin is a guide to calculating approximate amounts of material required, based on the bondline dimensions. “How much adhesive will I need?” also includes a link to download our Adhesive Usage […]

Read More

How to set up a pressure pot for dispensing

We have added a “how to” video to our YouTube channel. Setting Up a Pressure Pot for Dispensing is a short visual guide for preparing a pressure reservoir for dispensing materials such as adhesives, paints, lacquers, solvents, inks, coatings, oils and many other low to medium viscosity liquids from a pail or bottle. How to set […]

Read More

Side-by-side syringe cartridges – dispensing two part adhesives

Some of the two-part adhesives, sealants and other materials we supply are packaged in side-by-side syringe cartridges. In this packaging, the materials are already pre-measured in the correct ratio, saving time and material handling. The correct amounts of material are fed into a static mixing nozzle, which ensures thorough mixing whilst no air is introduced. The entire cartridge does […]

Read More

Twinpacks – mixing of adhesives and potting compounds

We supply a number of our adhesives and potting compounds in twinpacks. This convenient packaging offers benefits – the materials are pre-weighed in their correct mixing ratios, which saves time, and improves quality by removing the step of manually weighing out each part. Mixing within the twinpack reduces the handling of chemicals, cuts down on mess […]

Read More

adhere academy: premixed and frozen adhesives

You can buy two (or more) part adhesives which have been pre-measured into the correct proportions, mixed and degassed, filled into a dispensing syringe or cartridge, and then frozen to stop the cure. The adhesive is shipped from the factory to you in an insulated box also containing ice. Upon delivery, you store the adhesive […]

Read More

Adhesive Technology Seminars – performance and productivity

We offer a series of technical seminars to our customers in the technology manufacturing sector. The seminars focus on adhesives, protective materials and the associated application and curing equipment. The goal is to help design, production and quality engineers understand both the fundamentals and the cutting edge possibilities of the technologies, enabling you to deliver performance advances […]

Read More

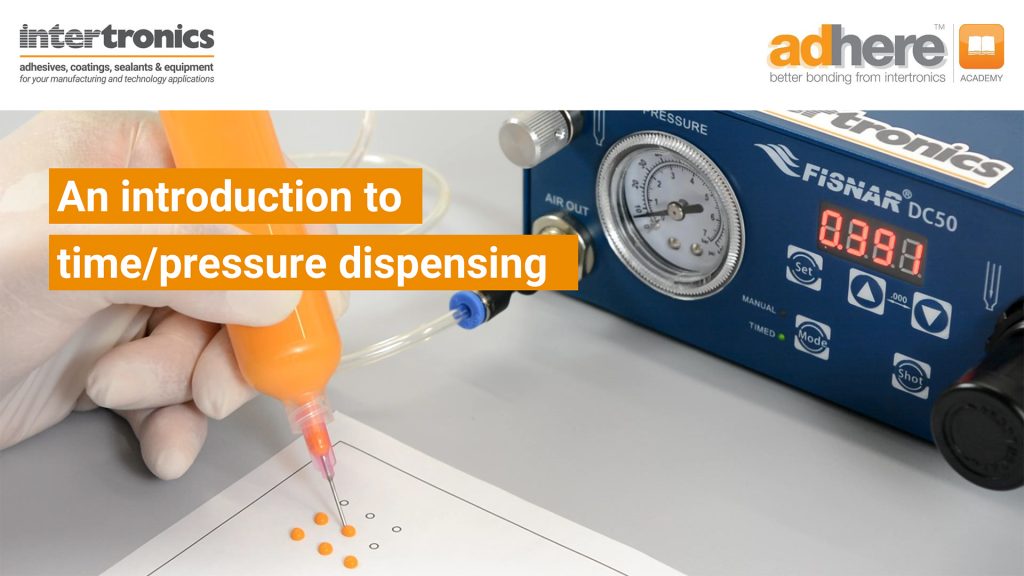

New introductory guide for time/pressure dispensing

Our new An Introduction to Time/Pressure Dispensing guide is a clear, simple overview for engineers needing to quickly understand this area of dispensing, or to use as a training aid for operators and new colleagues. Time/pressure dispensing lets you apply a wide range of liquid or paste materials by using a dispensing controller to apply […]

Read More

Introduction to time/pressure dispensing

If you ever thought about improving the manual application of your adhesives, oils, greases, solder pastes, sealants, inks or any other liquid or paste, then download a copy of our latest Technology Guide: An Introduction to Time/Pressure Dispensing. It talks about the advantages of this simple technology over brushing, daubing or squeeze bottles. The Guide […]

Read More

Seminar – The Art and Science of Choosing a Structural Adhesive

Please come to our seminar next week, Wednesday 9 September, entitled The Art and Science of Choosing a Structural Adhesive. We’ll be talking about how to choose the best adhesives, from the increasing number of structural adhesives on the market, to evaluate for your application. Starting with design and working through production and processing considerations, […]

Read More

Adhesive & coating dispensing seminar

Speed, accuracy and repeatability in the application of adhesives, protective coatings and other liquids can present problems to technology manufacturers, especially in a world where miniaturisation is a trend. Some insights will be given at our seminar Adhesive & Coating Dispensing – Meeting the Challenges of Technology Manufacturing at the FAST Exhibition on 22nd April, Silverstone […]

Read More

adhere academy: best surface finish/metallisation for conductive adhesives

We see many requirements for an electrically conductive bond formed with an adhesive. They vary from the micro (flip chips onto pcb’s, die-attach) to macro (wires onto sensors), and the range of projects is substantial. Often, our customers would like to use the adhesive in place of solder. The reasons include temperature restrictions, geometry, process […]

Read More

Seminar – Curing adhesives, coatings and sealants with light

We will be presenting a technical seminar on the subject of Curing adhesives, coatings and sealants with light at the forthcoming FAST Exhibition, September 10th at the Williams Conference Centre. Along with our presence in the exhibition itself, this will give you the opportunity to discuss the benefits with the team on our exhibition stand. In the […]

Read More

adhere academy: pot life v shelf life v working life – part 2

In part 1, we talked about shelf life. Let’s turn our attention to pot life and working life, and how they can affect both your specifying decisions and your process. Pot life and working life can be taken to mean the same thing, although in fact there are distinctions between the two terms. They can […]

Read More

adhere academy: pot life v shelf life v working life – part 1

We get a lot of questions about pot life and the terminology around it, so we’d like to provide some clarification. Nobody could be blamed for thinking that pot life describes how long the adhesive (or sealant, coating, potting compound or gasketing material) can remain useful in the pot they buy it in. And isn’t that the same […]

Read More

adhere academy: epoxy crystallisation

The problem – Occasionally, we get a call from a customer saying that there is “something wrong” with the epoxy he bought from us. One of the constituents of the two part system (usually part “A”, the resin) has become cloudy, milky, has crystals in it, has become lumpy or slushy, or has even become solidified. The […]

Read More

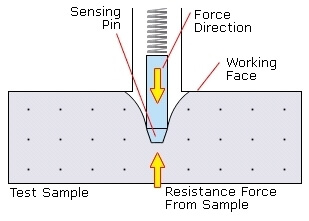

adhere academy: hardness

A recent adhere academy post discussed the modulus of elasticity of materials. Closely linked to that is another physical factor which we often quote on product data sheets: hardness. One way to define the hardness of a material is its resistance to permanent indentation. We all know that rubber balls are soft, and rock is hard, […]

Read More

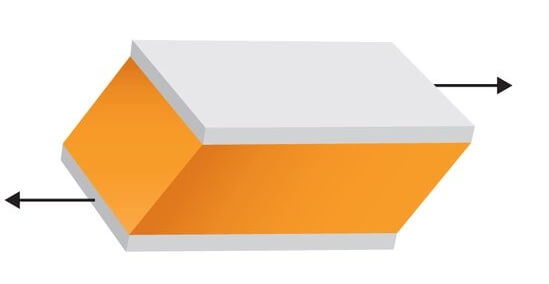

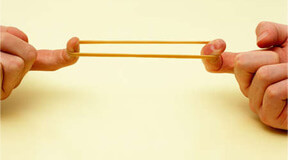

adhere academy: modulus of elasticity

Many of our material product data sheets (PDS) will quote a number for the modulus of elasticity. The modulus of elasticity is a number which represents the material’s tendency to be deformed elastically (i.e. non-permanently, recovering original size and shape) when a force is applied to it. A stiffer material will have a higher modulus of elasticity, […]

Read More

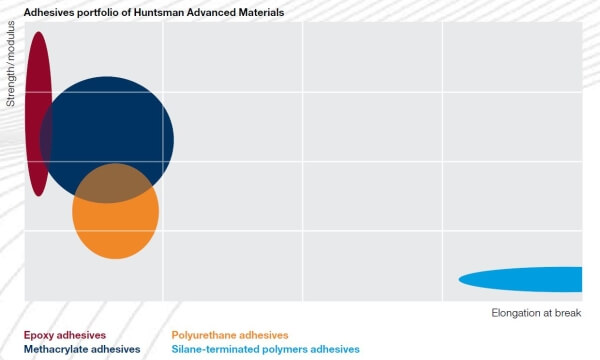

Structural adhesives – physical properties of chemical types

I was struck by this graphic from Huntsman Advanced Materials, manufacturers of the iconic Araldite range of structural adhesives. Choosing the optimal product to evaluate for your application can involve thinking about many factors, including environmental resistance, substrates to be bonded, cure speed, etc. This chart clearly illustrates how the physical properties of strength and […]

Read More

What’s a Luer Lock?

Most industrial dispensing systems rely on the Luer to fit dispensing needles, dispensing tips and other small fittings together. The Luer taper is a standardised (ISO 594) system for making leak-free connections between a male-taper fitting and its mating female part in the laboratory, industrial and medical world. Luer Slip fittings are simply held together […]

Read More