Robots are good for productivity, and if you’ve come to the conclusion that you can achieve a good return on investment through a robot purchase, you may find yourself wondering where to start with robot selection. We wrote a quick list of things to consider in our post How to specify a dispensing robot. Having been challenged to expand on determining work area requirements, our team got together to pool all their best advice on deciding how big a robot you need. We’ll discuss this in the context of using a robot to dispensing material such as adhesive, but the same considerations broadly apply for other functions such as robot-mounted UV light curing or plasma surface treatment.

In this blog, we’ll discuss the following considerations:

- Part size and jigging

- Production process

- Robot payload and physical constraints

- The material you’re dispensing

Part Size and Jigs/Tooling

What is the physical (3D) size of your part? Your part, including the jig it will sit within, needs to fit within the physical constraints of the robot. Don’t forget to consider the overall height (Z dimension) – too large, and you will need a gantry-style robot, rather than a benchtop robot, to accommodate your part.

What is the physical (3D) size of your part? Your part, including the jig it will sit within, needs to fit within the physical constraints of the robot. Don’t forget to consider the overall height (Z dimension) – too large, and you will need a gantry-style robot, rather than a benchtop robot, to accommodate your part.

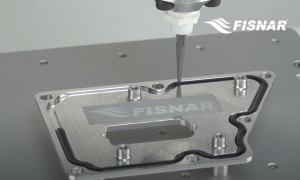

What is the actual dispensing area within the jig/part? Whilst jig or parts themselves can sit outside of the constraints of the dispensing area (as long as they still physically fit on the robot), you’ll want to ensure that the entire dispensing area is accessible by the robot head.

If you’re planning to process multiple parts in the same operation, you’ll need a robot large enough to accommodate the number of parts it needs to process and be able to access to all of the dispensing areas required. Having multiple parts in a jig usually helps with handling – for example, fewer loading and unloading steps.

Production Process

Consider the processes before and after the robot, and how parts/jigs/nests can transfer between them. Where is the bottleneck in the production line? An optimised production process has any potential bottlenecks at a point where the robot is waiting to carry out its task, rather than a human operator.

Consider takt time, the time it takes for your process to keep up with demand. You might say takt time is the satisfying rhythm of a production process optimally churning out parts to meet your customers’ need. One of the major benefits of a dispensing robot is its ability to carry out the dispensing process cleanly and repeatably, more quickly than a human could achieve the same results (if a human could even achieve the same results). You may want a larger robot or more robots to process more parts concurrently, so dispensing keeps up with your takt time requirements.

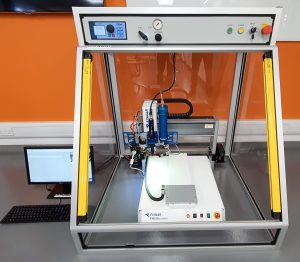

How much physical space do you have on your production line to accommodate a robot? While dispensing robots can be surprisingly compact (e.g., the Fisnar F4200N.2), you’ll want to include a safety enclosure and the space required for dispensing vessels such as pressure pots in your calculations if your production line is very tight on space.

Future-proofing: are you likely to need to accommodate either larger parts or more parts being processed concurrently either in the near or medium-term? Consider either buying a larger robot than is strictly required at the moment, or purchasing two smaller robots which together offer your forecasted processing requirements. Having two smaller robots also builds in redundancy, helping your production line to keep moving if there’s a machine outage (it happens to the best of us!).

Robot Payload and Physical Constraints

What is on the head of the robot? In addition to the machinery such as a dispensing valve, you’ll need to consider tooling, cables, syringes or cartridges of material, accessories such as height detection systems, camera vision systems, etc. In particular:

What is on the head of the robot? In addition to the machinery such as a dispensing valve, you’ll need to consider tooling, cables, syringes or cartridges of material, accessories such as height detection systems, camera vision systems, etc. In particular:

- How much is the work area/offset reduced as a result of what is mounted on the robot?

- Is the tool load capacity of the robot sufficient for carrying all of the above? Our Fisnar F4000 ADVANCE robots offer a tool load capacity of 5kg for 3- and 4-axis models, and 1kg for 5-axis models. The F4000 ELITE robots have increased tool load capacities, and Fisnar gantry robots offer tool loads up to 20kg.

Similar to tool load, how much work load capacity do you need your robot to have (i.e., how much do your parts, plug jigging, plus the material being dispensed add up to)? Our range of benchtop robots offers up to 25kg work load capacity; if your parts are particularly heavy, you may need to consider a gantry-style robot.

Let’s come back to Z-height: how tall are your parts, and will they fit under the robot mounted dispenser? This aspect of a robot is called “throat depth” – the distance between the surface your jig and parts will sit on, and the bottom of the robot head. Once your dispenser (or other device) is mounted and the dispensing tip attached, you might be cutting into throat depth and therefore reducing work area. For taller parts, a gantry robot may be needed instead of a benchtop robot, and a long dispensing tip might be needed to reach far enough into the part. You will still find constraints in the maximum travel distance of the robot’s Z-axis.

Lastly, understand your program requirements. Ideally, you don’t want to max out the dispense area of the robot so that you can build in some tolerance. Therefore, if your dispensing area is the maximum capacity of a robot’s work area, you will want to consider the next largest robot.

Material Being Dispensed

What is the working life of the material being applied? There’s no point in having a fast-curing material if the robot can’t keep up over multiple parts, and equally, there’s no point having a robot large enough to accommodate more parts than can be dispensed onto before the material cures.

What is the working life of the material being applied? There’s no point in having a fast-curing material if the robot can’t keep up over multiple parts, and equally, there’s no point having a robot large enough to accommodate more parts than can be dispensed onto before the material cures.

Get in touch to chat about your application with us, and we’ll help you figure out what you need. You can also book an appointment to visit our Technology Centre and experience our robots for yourself, alongside a warm welcome, a hot beverage and a free charge if you have an electric car.

Categories: dispensing, robotics