Category: quality control

Fluorescence in adhesives and coatings

I saw a newsletter article which said that fluorescent animals are much more common than previously thought. Researchers who studied 125 mammal species, including cats, bats, polar bears and wombats (pictured), found that all of them showed some form of fluorescence, and that 86% had fur which actually glowed under UV light. This picture is […]

Read More

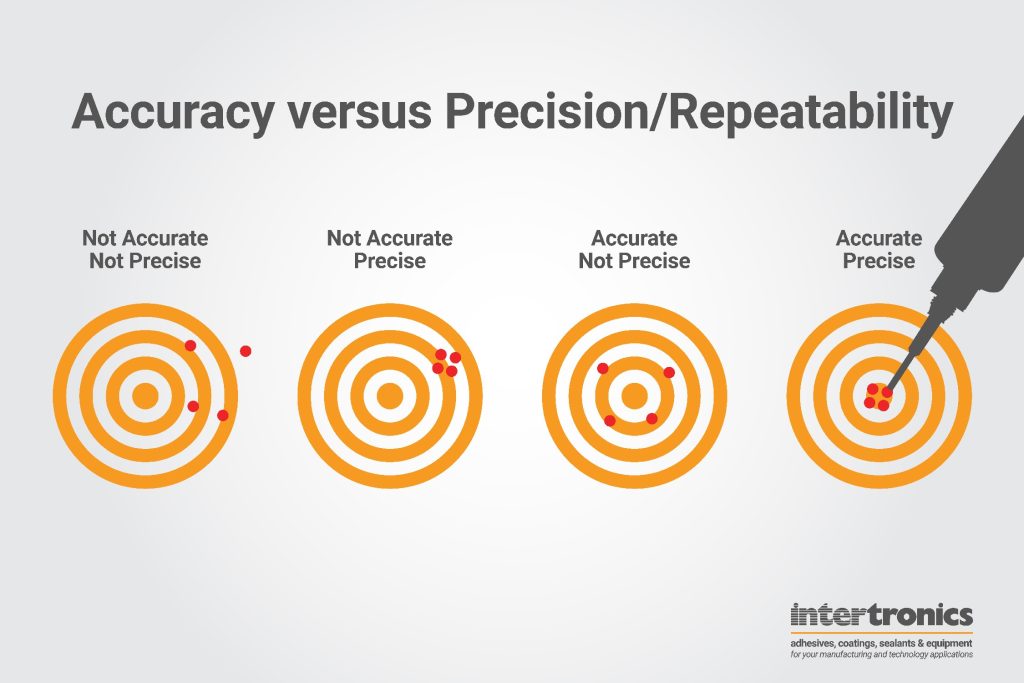

Dispensing: what do we mean by accuracy and repeatability?

A number of the products that we offer are described as being highly accurate, precise and/or repeatable. We believe that these criteria are important to a process where consistent, high quality output is required, and they have a big impact on productivity through reduction of material waste, quality-based rejects, and rework. But what exactly do […]

Read More

White Paper – dispensing quality measurement

The flowplus16 is an inline fluid sensor for monitoring the pressure of adhesive, coating or other material being dispensed or dosed. By understanding changes in pressure of material flow, consistency or other quality issues (like blockages or air inclusions) can be identified in order to produce consistent dosing results and dispensing quality. In this White […]

Read More

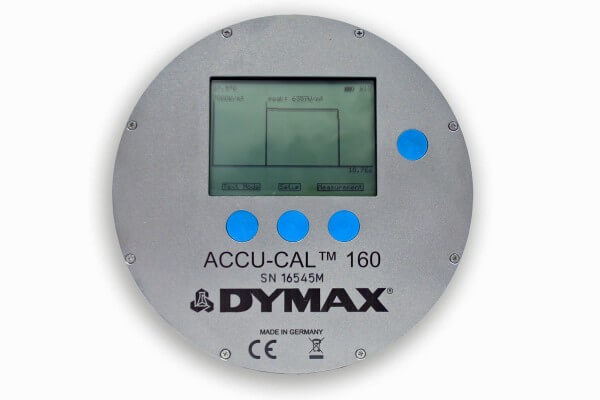

UV radiometer aids process control in broad spectrum or LED-based UV curing

The Dymax ACCU-CAL™ 160 Radiometer is an essential tool for users of UV curing processes, where both validating and subsequent monitoring of the lamp output is vital to consistent production quality. It is designed to be used with both benchtop flood curing lamps and conveyorised systems, and comes in two versions for either broad spectrum […]

Read More

How can I tell if the adhesive is cured? Encompass technology!

The new Dymax Encompass technology is now in a range of UV/visible light cure adhesives. Encompass combines the benefits of colour change once cured with red fluorescence for inspection. This combination offers the significant improvements in production efficiencies gained from rapid on-demand curing while ensuring greatly improved quality outcomes, since it is possible to quickly inspect […]

Read More

ISO 9001:2008 – quality audit passed with flying colours

We had our annual ISO quality audit this month. The Audit Team concluded that we have established and maintained our management system in line with the requirements of ISO 9001:2008 and that we have demonstrated the ability of the system to systematically achieve agreed requirements for products or services within the scope of our policy […]

Read More

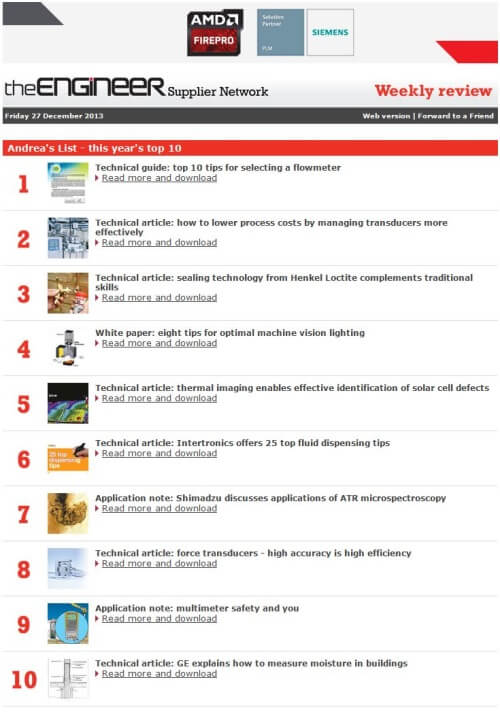

Our white paper is recommended at The Engineer this week

Read about the flowplus16, a new fluid pressure sensor for process control and validation in critical dispensing and dosing applications.

Read More

Fluid pressure sensor with luer-lock connections for medical applications

The flowplus16 is a high precision fluid pressure monitor device (up to 16 bar) designed from concept to exactly fit medical device criteria by including the standardised Luer-Lock connector system and internally, a void free flow channel coated with a virtually inert FDA compliant elastomer. In particular, the universal single size Luer-Lock system enables equipment […]

Read More

Article published: sensor for dispensing process control

We are proud to have one of our articles published in this month’s issue of Industrial Technology magazine. Entitled When you have to know your process is right every time…, it discusses our new flowplus16 fluid pressure sensor for process control and validation in critical dispensing and dosing tasks. Download a pdf copy right here!

Read More

White Paper: A new fluid pressure sensor for process control and validation

Just added to the Technical Bulletins, White Papers & Articles page on our website – a white paper entitled A new fluid pressure sensor for process control and validation in critical dispensing and dosing applications. It discusses the flowplus16 – a compact, inline, through-flow fluid sensor designed to deliver optimum process assurance for fluid dispensing or dosing […]

Read More

Compact inline pressure sensor for dispensing/dosing monitoring and verification

The new flowplus16 pressure sensor offers high accuracy monitoring in an innovative design suited to critical dosing and dispensing applications. Accurate in-line pressure sensing can deliver to you important quality assurance in a whole range of automatic processes – for example, in medical, pharmaceutical and semi-conductor manufacturing, as well as the wider areas of process control. […]

Read More

UV Blacklight for forensic inspection – featured on TV

Our IUV 250 UV Flood Lamp, combined with a Black UV-A filter, has many applications in forensic science. For example, at scene of the crime investigations, forensic scientists use ultraviolet blacklights to find blood, urine or semen – all fluorescent, and perhaps not visible to the naked eye. This is fully evidenced on television last night – […]

Read More

INTERTRONICS is certified to ISO 9001:2008

We are delighted to say that we have been certified to ISO 9001:2008 standard via an independent assessment conducted by the leading Certification Body, the British Assessment Bureau, demonstrating our commitment to customer service and quality in delivery. ISO 9001:2008 certification proves that our quality management system ensures consistency and a continuous improvement ethic; leading […]

Read More

Practical Components helps diagnose and treat Head-in-Pillow failure

Head-in-Pillow (HiP) soldering defects are common with modern SMT component placement. As a result, Practical Components has introduced the PBGA 928-HiP, a component that is designed specifically to be susceptible to HiP defects. It features a large 4×4 body size, 928 balls and a single small die that has a propensity toward the ball-in-socket HiP […]

Read More

Make sure your UV light curing process is on track

A consistent and reliable UV curing process requires periodic monitoring of the UV intensity or dose. Degradation of curing bulbs, lightguides and reflectors can decrease intensity, resulting in incomplete cures. The DYMAX ACCU-CAL 50 Radiometer is simple to operate, offers repeatable measurement of UV light and allows operators to monitor and document a UV/visible light […]

Read More

Seeing Red – For Accurate Bondline Inspections

An impressive new fluorescing adhesive technology, brought to you by our sales partner Dymax, will have you all “seeing red” to improve quality and authentication. The advantages of Ultra-Red™ technology are based on the fact that many plastics naturally fluoresce blue under UV blacklight – this minimises the inspection advantages of using conventional blue-fluorescing adhesives […]

Read More

Ultra-Red Adhesives for high contrast bond-line inspection and product verification

We are persuading our customers to “see red” literally. The Ultra-Red™ fluorescing technology built into many Dymax adhesives offers assemblers concrete advantages in plastics fabrication. Many plastics naturally fluoresce blue under UV light – this minimizes the inspection advantages of using blue-fluorescing adhesives in parts assembly. Ultra-Red™ fluorescing adhesives remain naturally clear until exposed to […]

Read More

Interview with our Dummy Man!

Electronics Production World has an interview with Kevin Laphen, President of our sales partners, Practical Components Inc. Practical Dummy Components is the exclusive distributor of mechanical samples for Amkor Technology as well as distributing components from most other leading SMD manufacturers. Practical has a worldwide distribution network (including us in the UK) and in-stock availability […]

Read More

Solder paste conditioning

If you store your solder paste in the fridge, then you need a process for getting it onto the production line and ready to use – which means it must be at room temperature and correctly mixed. The THINKY SR-500 Solder Paste Mixer and Conditioning Machine makes this process quick and foolproof. It is quick, […]

Read More

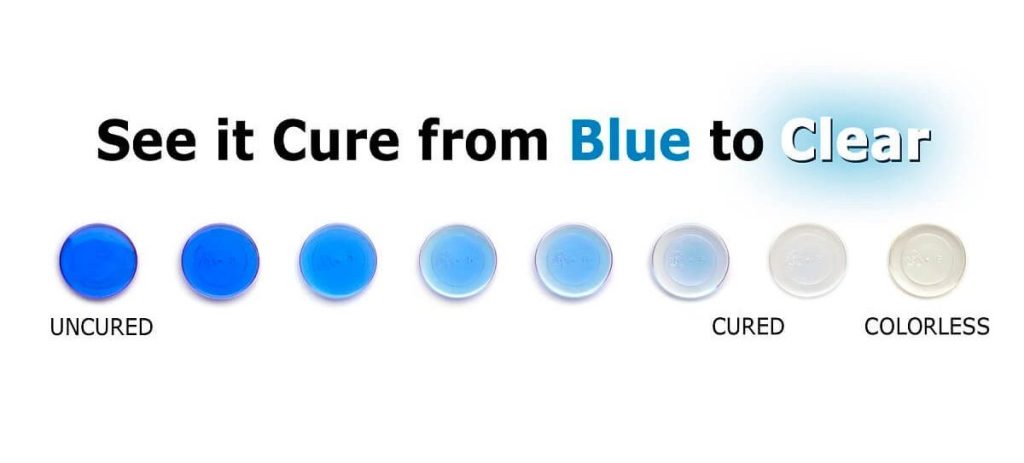

See-Cure – to be sure

Our sales partners DYMAX have created See-Cure technology as a visual indicator for their UV cure adhesives by colour changing from original blue to clear during the curing process. This innovative approach greatly aids industrial assembly processes, whether the application is medical, electronic, aerospace or automotive. In each case it is essential to know that […]

Read More

New DYMAX information sources

Our Sales Partners Dymax have been busy building special websites for some of their latest leading edge products. Check out: www.dual-cure.com UV and moisture cure conformal coating www.seeitcure.com Colour change on cure – a great innovation in process control www.ultraredadhesive.com Strong, red fluorescence for quality control These are exciting new resources for […]

Read More