When you are experiencing poor productivity from an adhesives process, the first step to resolving the issue is to identify why — there are several common pain points, including speed, quality and waste. If you identify that a material is holding you back, what can you do to reach your productivity potential?

Compared with mechanical fastenings, adhesives can sometimes be slower in a production process, because you may have to wait for them to cure before the product can move on to the next stage. A long cure time can lead to bottlenecks and increased work in progress. To speed up an adhesive cure, it may be an option to add heat to assist the reaction (for example, if an epoxy adhesive is being used). Alternatively, adhesive chemistries are available with inherently fast cure rates, and with the possibility of no compromise in functionality.

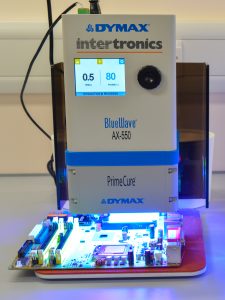

Many of our customers have found success using UV light curing adhesives, which cure rapidly and on-demand when exposed to light energy. Because they are single part and available in a range of viscosities, they require no special application equipment and are easy to use. UV curing materials lend themselves to automated processes, because the dispensing and cure is readily controlled and repeatable. Inspection can be facilitated by using a fluorescing or colour-change-on-cure material. In addition to structural adhesives, these benefits can be gained with UV light curing encapsulants, coatings and temporary masking materials.

There are two types of UV curing equipment – mercury arc and LED – which are based on two different types of technology. If you are using mercury arc lamps, there are some productivity drawbacks — a limited operational bulb life which requires regular bulb change, and an output intensity that degrades over time and which adds a process variable to be monitored and managed. These lamps require a warm-up/cool down time, mandating the use of mechanical shutters for exposure control.

Compared to traditional mercury arc lamps, there are productivity advantages to UV curing lamps based on the latest LED technology. Because LED lamps are instant on/off, they are activated only when needed, and do not need to be left running all day, saving energy consumption. Their intensity output has very little degradation over time, so process monitoring is simpler.

While they work in functionally similar ways, mercury arc lamps emit broad spectrum UV light, whereas LED systems emit narrow spectrum UV light. For an existing UV curing process, manufacturers wanting to take advantage of the productivity enhancement of LED technology should ensure that this different spectral output still cures their material to acceptable levels, meeting their functional tests. For a new project, it is recommended to trial adhesives which are formulated to be cured with UV LED lamps in order to reap all the productivity gains. The spectral output of the curing lamp should be correctly matched with the material that is being cured for best results.

Metering and mixing can also cause inefficiencies, waste or added process time. There has been progress in the design of meter, mix and dispensing equipment, providing better capability for challenging materials (those with very different viscosities or which are highly filled), as well as greater accuracy for smaller quantities. You may consider switching from a two-part to a single-part material, so that mixing is no longer required. The latest adhesives based on light curing acrylics or cyanoacrylate technology provide fast, single-part cures and excellent performance.

Changing materials is a complex approach and is not a decision that should be taken lightly. For regulatory reasons, it is particularly difficult for businesses working in medical or military applications to change a validated material in an established process. It may be simpler to identify how you can improve the process with equipment, such as automation or process control.

While we are here to support customers that want to change material and will provide guidance on what to look for and how to evaluate candidates, the best approach is to design a process with productivity in mind from the get go. We will consult with you on which materials will provide the required performance, balanced with an efficient, robust, repeatable process which suits your production volumes, not only now but in the future. Your chosen material should be able to be scaled, be suitable for future automation, and work within the process times available as numbers increase.

We have the expertise and experience to advise you on the changes to both your materials and processes. To make sure you reach your productivity potential, and gain an advantage over your competitors, give us a call.

Categories: adhesives, cyanoacrylate adhesives, productivity, uv curing