Bonding effectiveness, rapid cure time and process efficiencies have made light curing materials popular for manufacturers for assembly applications. Here, we share three tips for your UV curing processes. With a clear understanding of the UV curing process and the technology available, you can make informed choices and optimise your process.

Bonding effectiveness, rapid cure time and process efficiencies have made light curing materials popular for manufacturers for assembly applications. Here, we share three tips for your UV curing processes. With a clear understanding of the UV curing process and the technology available, you can make informed choices and optimise your process.

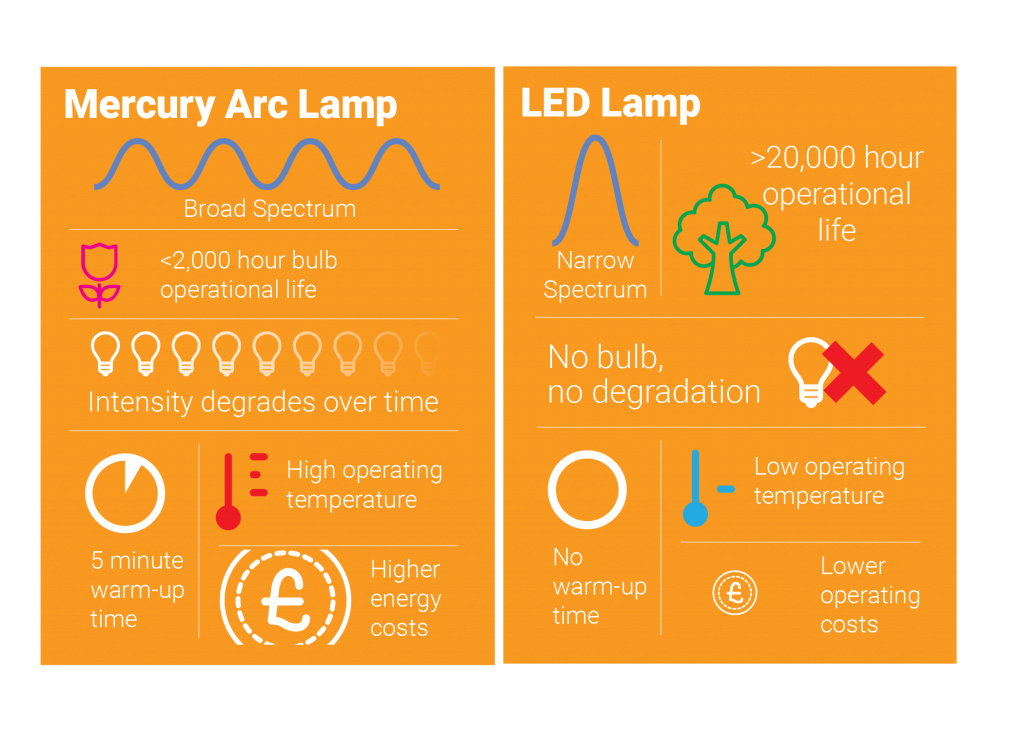

Broad vs narrow spectrum lamps

The two most common lamp types are broad-spectrum mercury arc UV lamps and LED-based UV curing lamps. Broad-spectrum lamps have a long history, but have some disadvantages like limited operational life of the bulb and a curing intensity that degrades over time. LED UV curing lamps are a more recent technology; their advantages include consistent output, no bulbs to replace and no warm-up time. However, they have a narrow spectral output based around a single wavelength.

You’ll see the best results when the cure requirements of the adhesive match the output of the curing lamp. Some adhesives, or other light curing materials like coatings and temporary masks, require a broader range of light energy to achieve tack-free and best cured properties. Matching the spectral output of the lamp to the light responsiveness of the adhesive is important in getting the ideal process.

What’s the dose?

One advantage of UV light curing is that complete cure is achieved in the bondline in seconds. Most UV curing adhesives start curing the moment you expose them to the correct wavelength(s) and intensity of light, and stop if the light is removed. So it is important that, in order to achieve full cure, the adhesive receives the correct dose of energy. Dose is a combination of light intensity or power, and exposure time. The higher the cure energy, the less time is takes to achieve full cross-linking, and vice versa.

You should determine the minimum light dose to achieve optimal cure for your application (by practical testing with production parts), and develop your process accordingly. Once you have established the minimum dose, best practice suggests that you add a safety factor to arrive at a robust process. Higher intensity lights will result in faster cures and process efficiency; more energy will generally help to give a better cure, improving performance.

Keep safe

UV light can be hazardous, but protection from the hazards is usually straightforward. A risk assessment will help understand the need for shielding or PPE. A radiometer will help everyone understand the emitted UV light. If using a hand-held curing device, eye protection is recommended as a rule. Exposed skin, on hands for example, can be shielded with gloves.

For more tips, check out our guide on “Top Tips for Getting the Best from Your UV Curing Process”.

Categories: adhere academy, technical guides, uv curing