Category: technical guides

adhere academy: how to prepare two-part cartridges for dispensing

Many adhesives, sealants, and potting materials are packaged in two-part side-by-side cartridges, which are convenient for material application on the production line or in the field. Cartridges don’t require you to measure out materials in the correct ratio, and by adding the manufacturer’s recommended static mixing nozzle, fully mixed and homogeneous material can be dispensed […]

Read More

Structural adhesives selector guide now available

To help you find the right adhesive for your manufacturing application, we’ve launched a Structural Adhesive Selector Guide. The guide provides a full overview of five structural adhesive chemistries: methyl methacrylate (MMA), epoxy, polyurethane, UV curing, and cyanoacrylate. It covers 28 materials and their properties, curing considerations, compatibility considerations, and more. We have designed the […]

Read More

Busting 10 misconceptions about robotic dispensing

The benefits of robotics are compelling to many manufacturers: improved productivity, efficiency, output, quality, and flexibility. They can also improve health and safety for employees and job satisfaction. The International Federation of Robotics World Robot Report in 2021 found that the UK has a robot density of 101 robots per 10,000 employees, far below the […]

Read More

25 top tips for optimally dispensing your materials

If your process involves dispensing materials like adhesives, inks, coatings, sealants, lacquers, paint, lubricants, or anything similar, our 25 Top Tips for Dispensing is worth a read – a collection of handy tips covering many dispensing applications which can help you fine-tune what you’re doing for optimal results. Covering dispensing pressures to types of dispensing […]

Read More

Dispelling 10 popular myths about cyanoacrylate adhesives

Cyanoacrylate adhesives (CAs) — also known as “superglue” or instant adhesives — are a popular adhesive choice for many applications, both industrially and domestically. Curing at room temperature in seconds, they provide excellent bond strength on a wide range of similar and dissimilar substrates including metals, plastics, elastomers, ceramics, and porous materials. Achieving these throughput […]

Read More

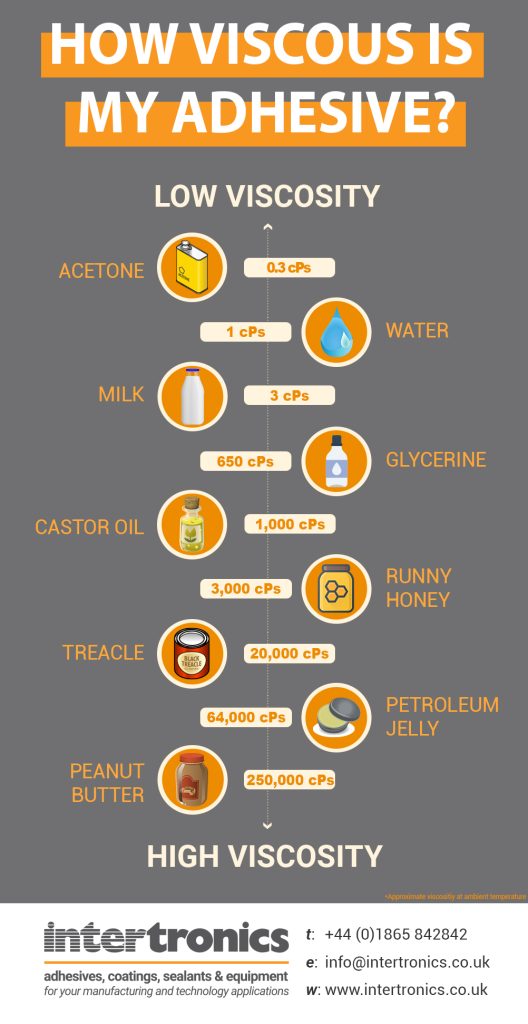

adhere academy: what is viscosity?

Viscosity is the resistance of a fluid to flow. This means that different fluids with different viscosities will flow at different rates under the same force. The higher a viscosity a fluid has, the harder you have to push it to move it. We call a higher viscosity fluid more viscous. You can see why […]

Read More

e-book: 7 ways UV temporary masking helps in electronic assembly

This new e-book from our partners Dymax is entitled Smart Connected Device Assembly – 7 Ways Light Curable Maskants Can Provide Protection. Covering seven different electronics assembly processes, including soldering, coating, and surface treatments, the benefits of uv light curable temporary masking products are clearly described. It is worth downloading a copy!

Read More

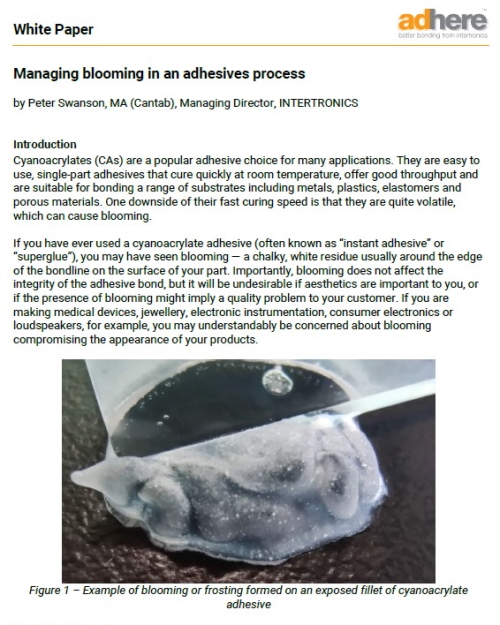

White Paper: What is cyanoacrylate adhesive blooming, and what can you do about it?

What is cyanoacrylate adhesive (CA) blooming, and what can you do about it? That is the subject of our latest White Paper, entitled Managing blooming in an adhesives process. The article discusses what is blooming, how it happens, and methods to reduce or eliminate it. Importantly, blooming does not affect the integrity of the adhesive […]

Read More

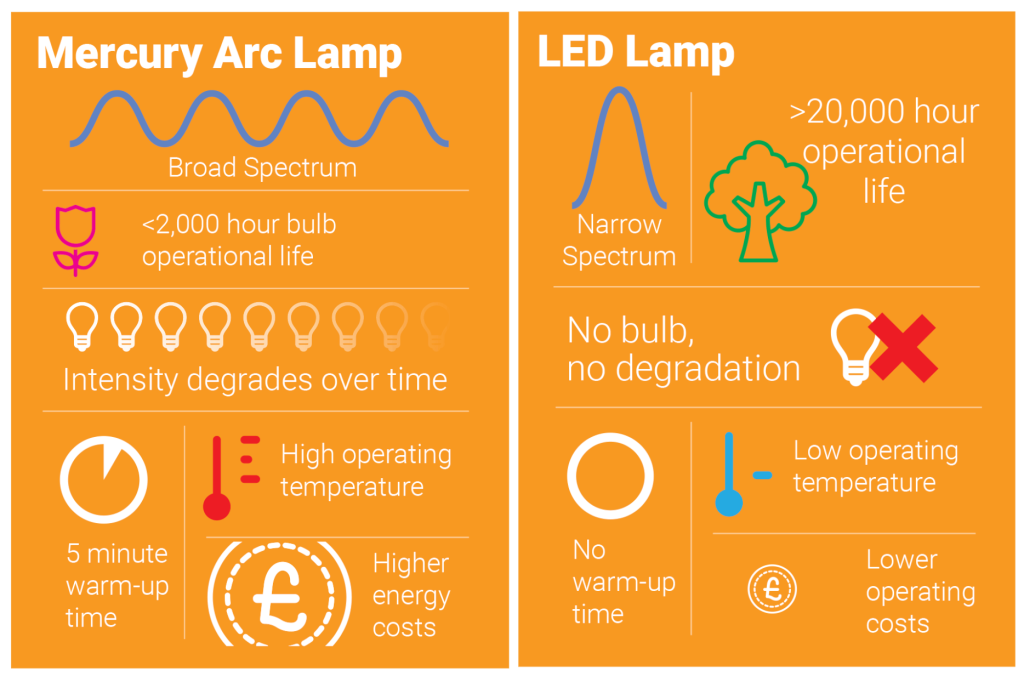

adhere academy: UV curing tips and tricks

Bonding effectiveness, rapid cure time and process efficiencies have made light curing materials popular for manufacturers for assembly applications. Here, we share three tips for your UV curing processes. With a clear understanding of the UV curing process and the technology available, you can make informed choices and optimise your process. Broad vs narrow spectrum lamps The […]

Read More

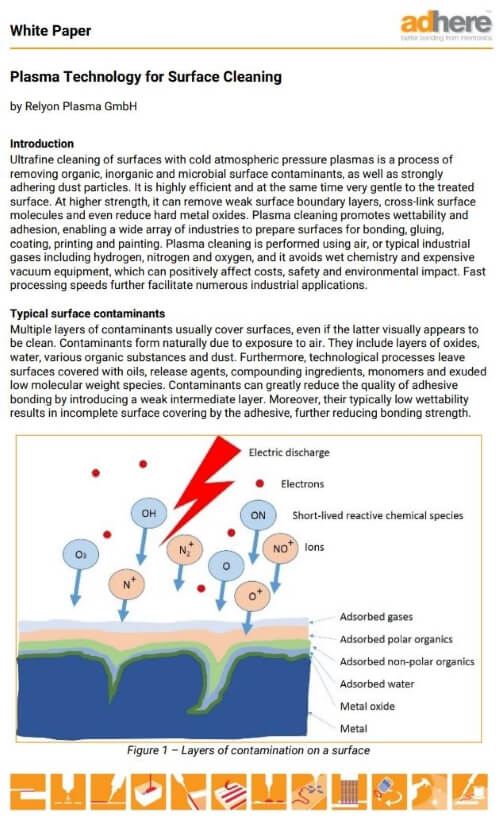

White Paper: Plasma Technology for Surface Cleaning

Whilst our customers typically use plasma technology to improve their bonding, another use of plasma is ultrafine surface cleaning. Relyon Plasma, our sales partner, has produced an in-depth explanation of how plasma technology can clean surfaces, which we have added to our library of technical resources. You can read the White Paper on Plasma Technology […]

Read More

How much adhesive will I need?

We have added a new Technical Bulletin to our Technical Resources to help answer the commonly asked question: “How much adhesive will I need?“. The Technical Bulletin is a guide to calculating approximate amounts of material required, based on the bondline dimensions. “How much adhesive will I need?” also includes a link to download our Adhesive Usage […]

Read More

How to set up a pressure pot for dispensing

We have added a “how to” video to our YouTube channel. Setting Up a Pressure Pot for Dispensing is a short visual guide for preparing a pressure reservoir for dispensing materials such as adhesives, paints, lacquers, solvents, inks, coatings, oils and many other low to medium viscosity liquids from a pail or bottle. How to set […]

Read More

Side-by-side syringe cartridges – dispensing two part adhesives

Some of the two-part adhesives, sealants and other materials we supply are packaged in side-by-side syringe cartridges. In this packaging, the materials are already pre-measured in the correct ratio, saving time and material handling. The correct amounts of material are fed into a static mixing nozzle, which ensures thorough mixing whilst no air is introduced. The entire cartridge does […]

Read More

Twinpacks – mixing of adhesives and potting compounds

We supply a number of our adhesives and potting compounds in twinpacks. This convenient packaging offers benefits – the materials are pre-weighed in their correct mixing ratios, which saves time, and improves quality by removing the step of manually weighing out each part. Mixing within the twinpack reduces the handling of chemicals, cuts down on mess […]

Read More

New introductory guide for time/pressure dispensing

Our new An Introduction to Time/Pressure Dispensing guide is a clear, simple overview for engineers needing to quickly understand this area of dispensing, or to use as a training aid for operators and new colleagues. Time/pressure dispensing lets you apply a wide range of liquid or paste materials by using a dispensing controller to apply […]

Read More

New guides to electrically conductive & thermally conductive adhesives

We have issued two new guides which offer an introduction to the Electrically Conductive Adhesives and Thermally Conductive Adhesives produced by Polytec PT. Each guide gives a descriptive overview of the technology involved and related product applications in industries such as microelectronics, electrical engineering, power engineering and general energy. New, next generation technologies are introduced. Conventional […]

Read More

adhere academy: pot life v shelf life v working life – part 2

In part 1, we talked about shelf life. Let’s turn our attention to pot life and working life, and how they can affect both your specifying decisions and your process. Pot life and working life can be taken to mean the same thing, although in fact there are distinctions between the two terms. They can […]

Read More

adhere academy: pot life v shelf life v working life – part 1

We get a lot of questions about pot life and the terminology around it, so we’d like to provide some clarification. Nobody could be blamed for thinking that pot life describes how long the adhesive (or sealant, coating, potting compound or gasketing material) can remain useful in the pot they buy it in. And isn’t that the same […]

Read More

Read our top rated article on The Engineer’s 2013 list

We were quite excited when we came back from our Christmas break to find out that our article 25 Top Dispensing Tips has been listed on The Engineer’s Supplier Network as one of their top 10 for the year. If you haven’t read it yet, please get a copy from our website!

Read More

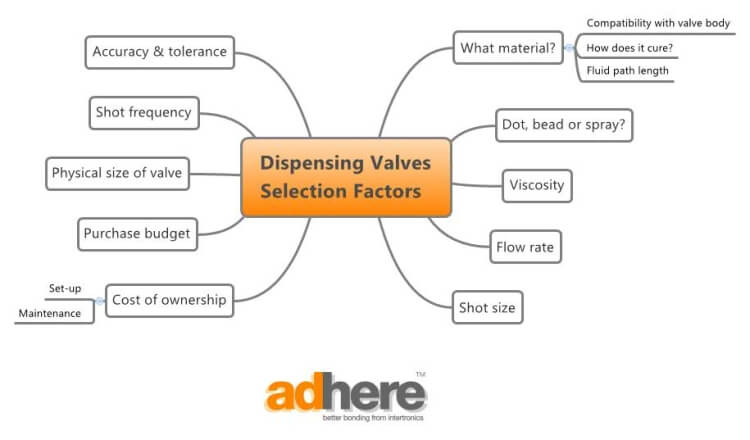

Dispensing valve selection factors

During some in-company training recently, we came up with the most important factors we need to consider when helping our customers select a dispensing valve for the application of inks, adhesives, coatings, sealants, glues, potting compounds and the like.

Read More

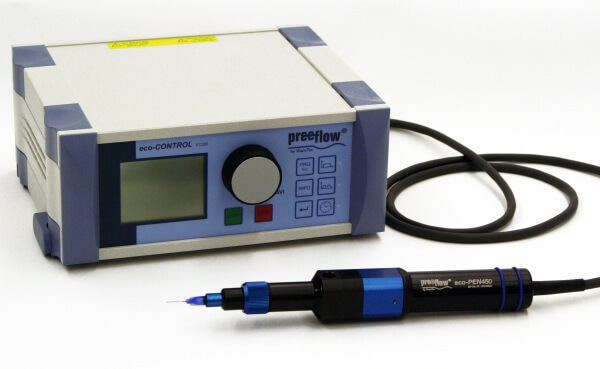

White Paper: Technology for Precision Dispensing

Just added to our webpage Technical Bulletins, White Papers & Articles – a new white paper entitled The “Endless Piston” Pump – Technology for Precision Dispensing. It discusses the technology behind our preeflow eco-PEN precision volumetric, positive displacement, dosing/dispensing systems. Why don’t you have a quick read?

Read More

DYMAX Industrial Adhesives Selector Guide – Glass, Metal & Plastic Assembly Adhesives

A reminder to download and have a look through the Dymax Industrial Adhesives Selector Guide. The latest 16 page version details the range of Glass, Metal & Plastic Assembly Adhesives – all designed to offer manufacturers complete solutions to optimise the speed and yields of your assembly process.

Read More

Technical Guide on Adhesive Cure Methods – Free Download

The use of adhesives for structural bonding is on the increase. For a successful assembly, the adhesive must “harden” in the bondline to provide a joint which is capable of bearing the forces to which it is subjected for its lifetime, whatever environmental factors are thrown at it. Understanding how this works is important both […]

Read More