Category: 3D printing

Case study: improving mixing accuracy and repeatability for 3D printed bioelectronics research

To improve the way recovery from injury and the progression of neurological/musculoskeletal conditions are monitored, the Department of Automatic Control and Systems Engineering (ACSE) team at the University of Sheffield is developing a diagnostic glove that includes several flexible bioelectronic sensors. The sensors are formed from elastomers mixed with various conductive nano or micro particle […]

Read More

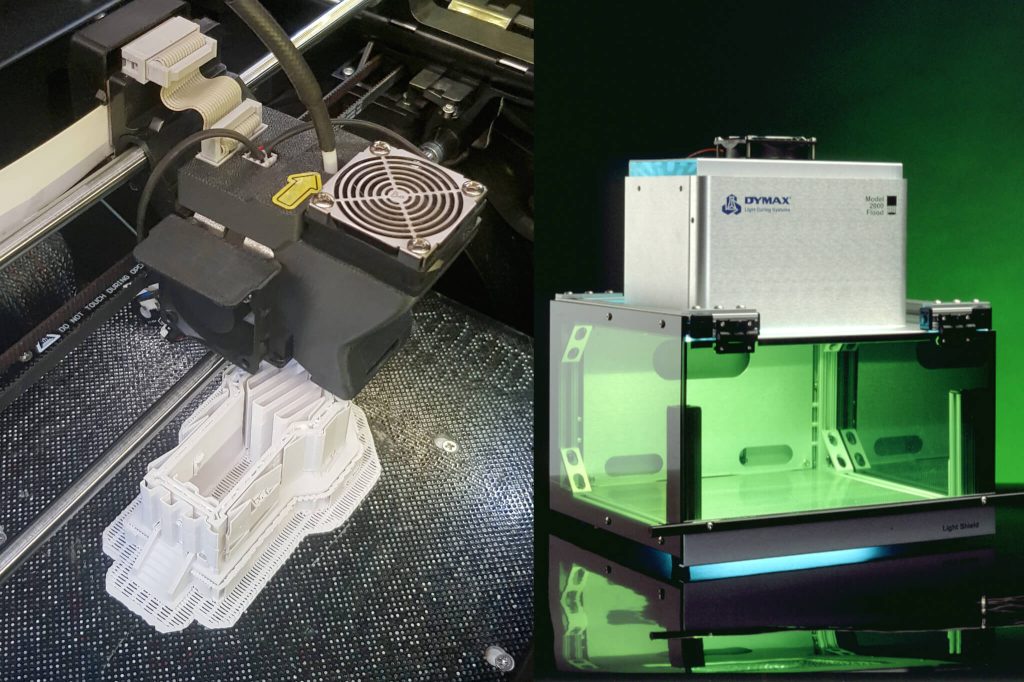

Case study: bonding 3D printed parts

3D printers usually print relatively small stuff – certainly less than 1 meter in any dimension. Our own 3D printer’s largest build dimension is 320mm, and that is fairly common. There are exceptions, of course – these days you can 3D print a two-story house. But for most applications, if you need to make a […]

Read More

Shining a light on UV curing for 3D models

Design teams test the aerodynamics of a Formula 1 car by putting a prototype in a wind tunnel. Engineers often use smaller scale 3D models during testing – but how can they be sure that the prototype will be up to scratch? The time-scales and competitive nature of Formula 1 mean that engineers must quickly […]

Read More

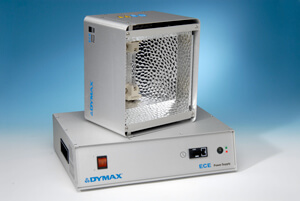

UV post-cure for 3D printing

Recent developments in 3D printing (also known as additive manufacturing or rapid prototyping) have popularised the SLA (stereolithography) methodology of laser printing in a bath of UV light curable photopolymer resin. This process effectively “grows” a component in the bath so that as it is withdrawn, each successive layer is light cured. It is a process […]

Read More