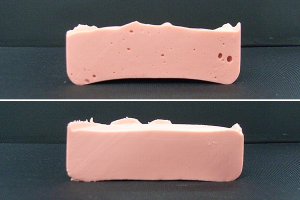

Formulators of potting materials for aerospace electronics applications are careful not to supply products with entrapped air. Consequently, entrapped air is usually a processing issue which can compromise thermal conductivity and heat dissipation, or the electrical insulation properties. Voids and delamination can also provide pathways for moisture and other contaminates, weaking the physical structure. If you need to avoid voids at all costs, there are some things you can try.

Processing issues

Correct storage is important in ensuring that the compounds do not absorb moisture. Some chemistries are hygroscopic and readily absorb moisture from the air, which reacts to form a gas. They are packaged in airtight containers and/or with desiccants. Taking care in handling the materials in accordance with the manufacturer’s recommendations can prevent problems later.

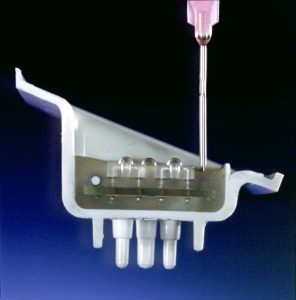

Non-contact methods of mixing, such as planetary centrifugal mixers or automated metering and mixing systems, typically introduce less air than other mixing methods. If you’re using metering and mixing equipment, ensure this is regularly maintained and avoid introducing air during replenishing. If air inclusion from mixing is unavoidable, then you should consider removal via degassing.

Low viscosity materials may be able to adequately degas themselves. For best results, use a container with a large surface area and shallow depth and scoop off any bubbles that rise to the top and remain. For higher viscosity products, or where production time doesn’t allow for unaided degassing, vacuum can expedite the process. If the mixed working life is sufficient, vacuum chambers may be used for degassing. Avoid using excessive vacuum, as some constituents can be volatile and will evaporate at lower pressure, altering the material’s formulation.

Centrifugal force can also be used to degas the material before application. In practice, we often see this when using a planetary centrifugal mixer, which mixes and degasses plural component materials of multiple viscosities, and also powders. The non-contact mixing action (revolution and rotation) does not add air, instead it tends to remove it. An additional “defoaming” mode applies a more direct centrifugal force to the mixed materials, separating out the air. Care must be taken not to separate any fillers or heavier constituents with the centrifugal action.

For critical applications, these planetary centrifugal mixers can be configured so mixing happens under vacuum. Many of our aerospace customers have seen success with the THINKY ARV-310 Mixing and Vacuum Degassing Machine.

Application methods

Once your compounds are mixed, it is important not to introduce or entrap air during application. Techniques to eliminate or minimise air bubbles in the completed assembly include pouring or injecting in stages, driving out air rather than trapping it under components. Tilting the assembly, filling from the bottom and perhaps preheating to reduce viscosity and surface tension can help.

In critical applications that are geometrically challenging, potting can be done under vacuum, or the potted unit can be vacuum degassed before cure. Another tactic is to place potted parts onto a vibrating table, helping to release trapped air.

Pressurised feed systems can also saturate the material with dissolved air, which can result in bubbles later on. It is good practice to depressurise systems when inactive, and to use only the required pressure. Alternatively, this can be avoided by having a barrier between the compressed air and the potting compound, or by using a pump.

Contamination and cure

The uncured potting compound or encapsulant can react with contaminants, potentially causing a lack of adhesion and subsequent delamination, or the formulation of gas bubbles, both of which cause voids. Contamination issues can be resolved by using cleaned and dried assemblies.

Shrinkage of the compound during cure may create voids in parts of the assembly. Again, applying the materials in stages can minimise this by allowing the materials to fill any gaps left by the shrinkage.

Avoiding voids in aerospace PCBs is essential for the final assembly’s performance. By carefully considering each stage of their potting process, manufacturers can avoid voids and create parts with reliability and longevity.

Categories: aerospace, mixing, potting compound