Dispensing and dosing small quantities (microlitres) with volumetric precision can be a headache for many companies in sectors such as electronics and semiconductor manufacturing, aerospace, medical device assembly and pharmaceuticals. Having to maintain accuracy whilst also meeting throughput and productivity demands may have traditionally pushed manufacturers towards complex, multi-system processes in order to achieve their goals.

In conjunction with our partners preeflow, we aim to reduce the burdens and pressure points that you may face by offering the ‘eco’ range of dispensing technologies, offering one-component (eco-PEN), two-component (eco-DUO) and spray dispensers (eco-SPRAY) to satisfy a myriad of potential dispensing operations.

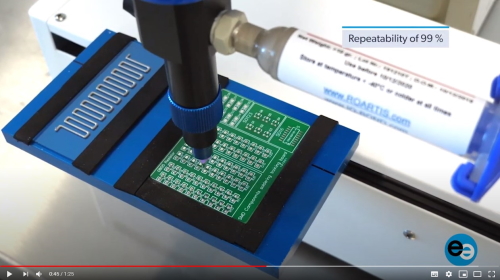

Operating using an ‘endless piston’ progressive cavity pump technology, the dispensers offer pulsation-free, purely volumetric dispensing and dosing to an accuracy of +/-1%, regardless of viscosity, for materials which include silicones, adhesives, greases, oils, resins, sealants or pastes, to name but a few.

Each product within the range can be operated in manual, semi-automated and fully automated environments, and can be used as stand-alone units or integrated into much larger integrated assembly processes. The dispensers collectively use the same precise control system which includes integrated pressure monitoring as well as the ability to set dispensing quantities, mix ratios and dispense time.

Specifying the same basic technology across a range of your material application processes can simplify your life, through streamlined training needs, familiar operating instructions, common spares and a single source of service. Give us a call.

Dispensing electrically conductive adhesive for strain gauges and SMT

Categories: dispensing