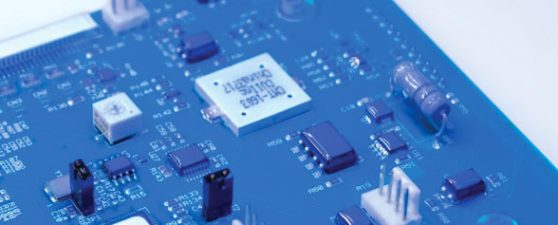

Electronics Assembly and Production

Confidently specify your electronics assembly adhesive materials and equipment from a single supplier with an understanding of the whole process.

We supply electronics manufacturers with adhesives, sealants, gaskets, coatings, potting, encapsulation, and temporary masking materials along with the equipment necessary to prepare, mix, dispense, and cure them. Whether you are creating a prototype or preparing for production, we can assist with adhesive material selection and methodology for processing those materials.

A focused, synergistic range of products

We can help you with:

Adhesive materials

Adhesive materials

- Bonding

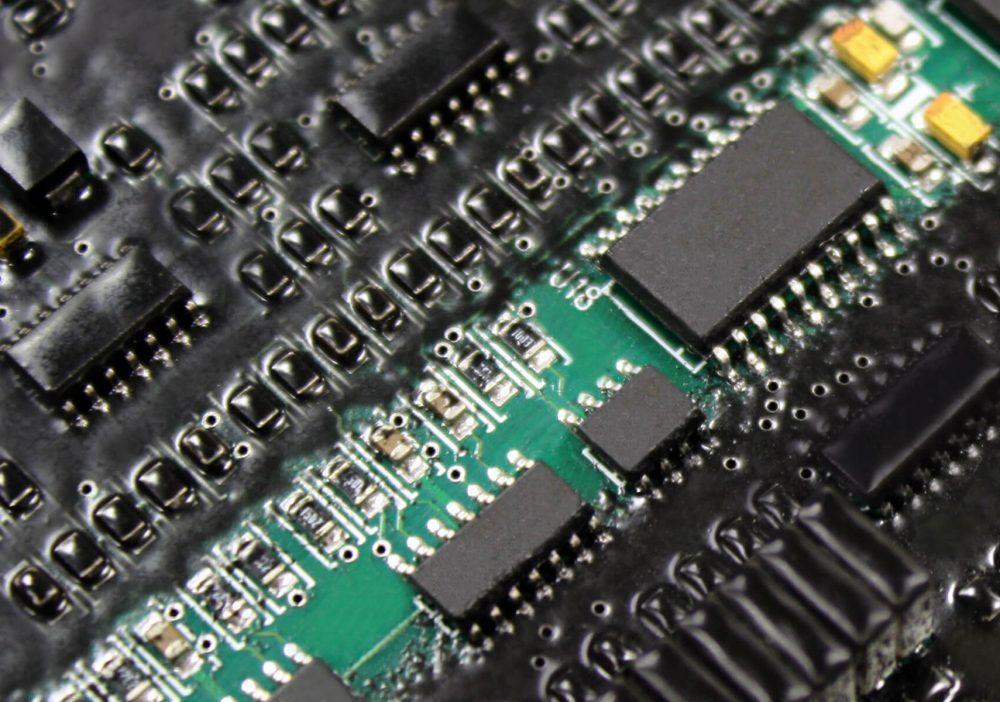

- Ruggedising

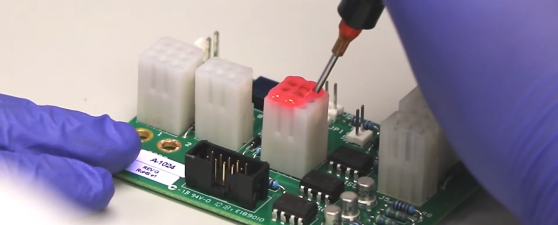

- Tacking or staking

- Thermally or electrically conductive applications

Protective materials

- Sealing

- Gasketing

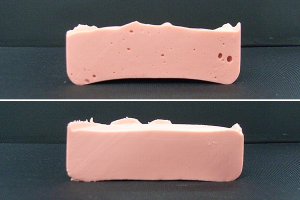

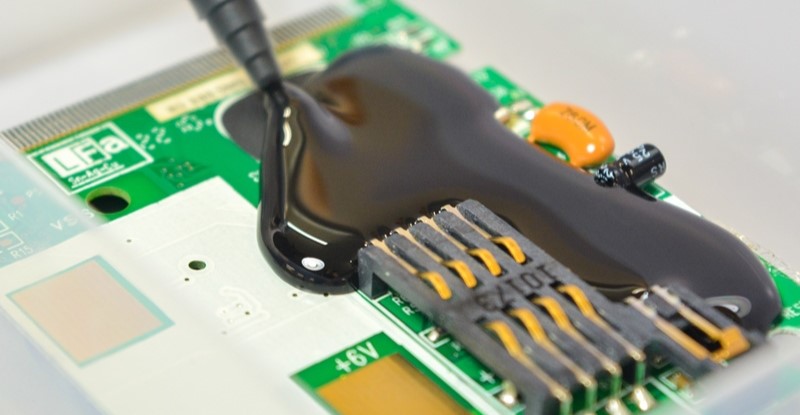

- Potting

- Encapsulating

- Coating

- Temporary masking

Matched equipment – either manual, technology-assisted, or automated

Matched equipment – either manual, technology-assisted, or automated

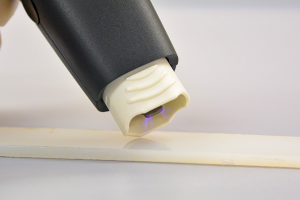

- Dispensing/application

- Surface preparation

- Material preparation

- Curing

- Mixing and metering

- Robotics

Consumable products

- Dispensing tips, needles, syringes, etc.

- Cleaning products

- Surface preparation

Achieving your desired outcomes

Our more than 40 years’ experience working with the electronics industry gives us the insight and expertise to consult with you focussing on the specific outcomes you are hoping to achieve. We will ask you intelligent questions and work to provide proof of concept through

- Assistance and guidance with material evaluation

- Demonstrations at our Technology Centre

- Coordinated lab trials and written reports with outcomes

- Onsite demonstrations and evaluations

- Samples

We focus on meeting your desired results.

Providing support throughout the product lifecycle

Once your materials and equipment are specified and put into place, we offer technical support throughout the production lifecycle, including help with control and efficiency around your adhesives process. We will work with your purchasing and logistics teams to maintain a consistent supply of your specified material(s), including flexibility to offer scheduled orders, KANBAN or call-off ordering as required. Many of our electronics-related products are in stock at our UK warehouse for next day delivery, avoiding international shipping delays and logistical headaches.

Proven success in the electronics industry

Here are some examples of customer success we have helped to facilitate, and some of our technical resources for electronics applications:

Case study

A sensor manufacturer reports saving 23 days per year of production time by using the preeflow eco-DUO dispensing valve

Case study

An underwater instrument manufacturer completed product development in six weeks with our potting compounds and process advice

Case study

A chemical analysis systems manufacturer more than doubled their output with Vermes jetting valves

Let’s start by talking about your application

01865 842842

info@intertronics.co.uk

Get in touch and we’ll respond within the business day