Medical Device Assembly

Medical device adhesives, protective materials, and equipment for your process reliability, repeatability, and validation

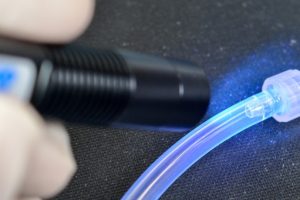

We supply ISO 10993 and USP Class VI medical device adhesives and protective materials – and the associated dispensing and curing equipment – for bonding, coating, sealing and masking of plastics, metal, ceramics, glass, and other substrates commonly used in the medical device assembly industry

Our adhesives and protective materials bond to your substrates, withstand the rigours of your product end-use, and comply with the regulatory needs of the industry. We offer compatible equipment technologies for surface preparation and cleaning, mixing, dispensing, and curing to ensure further verifiable and consistent control of your efficient, repeatable, validated process.

Our adhesives and protective materials are:

Applications include the bonding, coating or temporary masking of:

Comprehensive knowledge, seamless support

We will advise you on suitable adhesives and associated dispensing and curing methods for your products and processes. We will help you evaluate these materials and equipment and provide ongoing technical and supply chain support throughout the lifetime of your production.

Materials

- Dymax medical grade UV curing adhesives, coatings and temporary masking materials

- Opti-tec medical grade epoxy adhesives

- Polytec PT medical grade epoxy and conductive adhesives

- Wacker medical grade silicones

- Medical grade cyanoacrylate adhesives

Equipment

- Comprehensive range of UV and UV LED light curing equipment and accessories

- Manual, semi-automatic and fully automatic dispensing equipment

- Precision dispensing/dosing

- Mixing, metering and degassing systems

- archytas series robot integrations incorporating any of the above

- Plasma surface treatment systems

Insights into our work in medical device assembly:

Let’s start by talking about your application

01865 842842

info@intertronics.co.uk

Get in touch and we’ll respond within the business day