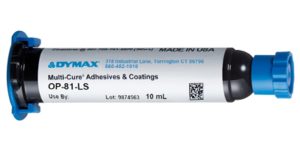

We have introduced Dymax Low Shrink™ OP-81-LS UV adhesive, which offers very low volumetric shrinkage. Designed for optical assembly applications that require precise alignment, the material cures in seconds on exposure to UV/visible light. It is single-part, solvent free and can bond dissimilar substrates — it is recommended for materials including polycarbonate, glass, acrylic, metal, LCP and FCP.

OP-81-LS has very low volumetric shrinkage during cure. Its epoxy chemistry enables a low coefficient of thermal expansion (CTE) and high glass transition temperature (Tg) for stability through thermal cycling, and low outgassing, meeting ASTM E595 outgassing requirements. Its properties make it well suited for optical positioning, active alignment, and bonding lenses, prisms, windows, fibers and other optical components.

To some extent, all adhesives shrink during curing. This can cause stress on the parts and lead to focussing and alignment issues during processing. Standard epoxy adhesives can have a shrinkage of around 3 to 5%, so many in the optical or optoelectronics field have turned to specially formulated adhesives. This new material offers very low linear shrinkage on the order of 0.01%, which means there is low to no movement during cure.

UV light curing materials are helping optical engineers to meet the productivity and performance requirements of today’s manufacturing environments. Two-part optical epoxies, for example, take minutes to days to cure where UV curing materials take just seconds. Cure takes place on-demand, which is beneficial during alignment and focussing as you have time to ensure positioning is correct before cure is initiated. Fast, on demand curing reduces work in progress and frees jigs and fixtures for the next assembly.

Dymax OP-81-LS is fully curable in seconds with broad spectrum or LED UV curing lamps. It also features a low temperature (80-85⁰C) heat-curing function that can be used as the sole cure mechanism where heat cure is preferred or as secondary method in applications where shadow areas exist. The new material complements our existing range of products for optical applications, which includes adhesives and synergistic precision application, dispensing and curing equipment.

Categories: adhesives, automotive, optics, uv curing, what's new