Category: composites

MMA structural adhesives in aerospace: an overview

Important properties for a structural adhesive in an aerospace application are strength, toughness, and flexibility, alongside temperature and environmental resistance. When choosing an adhesive, methyl methacrylate structural adhesives (MMAs) may be a good candidate to test, as these adhesives offer strength, toughness, and ease of use when bonding a broad range of materials, including metals, […]

Read More

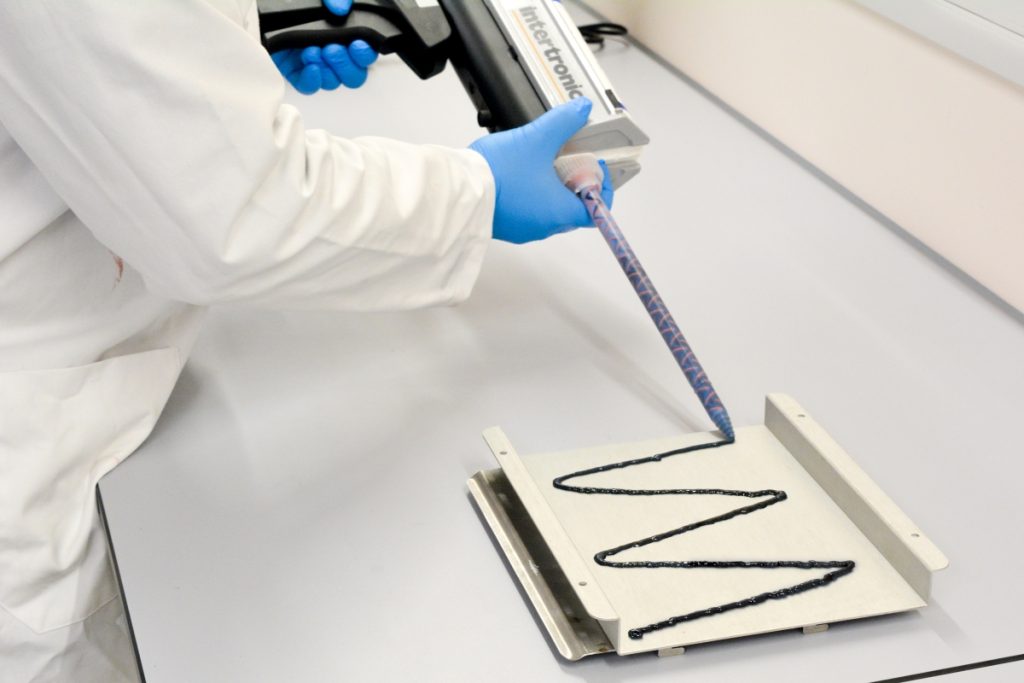

Structural adhesives selector guide now available

To help you find the right adhesive for your manufacturing application, we’ve launched a Structural Adhesive Selector Guide. The guide provides a full overview of five structural adhesive chemistries: methyl methacrylate (MMA), epoxy, polyurethane, UV curing, and cyanoacrylate. It covers 28 materials and their properties, curing considerations, compatibility considerations, and more. We have designed the […]

Read More

High temperature adhesive for metal bonding in automotive, rail and component manufacturing

SCIGRIP® SG800 High Temperature MMA Methyl Methacrylate Adhesive is a two component structural adhesive for bonding metals, as well as composites and plastics. Designed to withstand temperatures up to 150°C over prolonged periods, SCIGRIP SG800 is suitable for applications like under the bonnet engine bay component assembly and metal bonding prior to paint baking cycles. It displays good strength […]

Read More

Intertronics becomes UK distributor of Scigrip MMA adhesives

We’ve partnered with SCIGRIP to distribute its methyl methacrylate adhesives (MMAs) in the UK. MMAs are fast curing, two-part structural adhesives that cure on mix at room temperature to form resilient bonds. They are ideal for structural bonding of metals, plastics, and composites in industries like marine, transportation, rail, automotive, and many others. MMA technology […]

Read More

Point-One™ polyurethane adhesives do not require REACH training

The upcoming REACH training and certification requirements for users of diisocyanates are looming ever closer, impacting your use of many polyurethane adhesives in industrial applications. If you haven’t heard about this, read more here. Point-One Structural Polyurethane Adhesives are fast-curing two-part adhesives that form strong, durable bonds in as little as 10 minutes. They are […]

Read More

Adhesives in the real world: success stories from our customers

Our customers are doing amazing things, so we’d like to highlight some of their achievements and perhaps provide you with a bit of inspiration for ways to improve your productivity while achieving a great return on investment. Here’s a snapshot of some of our recent case studies: ShotScope has been able to quadruple production of […]

Read More

Time to bond with plasma technology

The January/February 2019 issue of Plastic News Europe features our article Time to bond with plasma technology. The piece concludes: “Plasma is not limited to natural phenomena like stars and the Northern Lights. Manufacturers should consider plasma treatment if they are frequently faced with difficult-to-bond substrates. The benefits can be particularly compelling for medical device, […]

Read More

Factors for consideration when bonding composite materials

Composites continue to be the subject of rapid advancement in terms of formulation, production and types of applications. Incorporating composites in your assemblies requires adhesives that contribute to the highest possible performance and reliability, exploit their qualities of strength and light weight and meet the demanding conditions of the automotive, defence, aerospace, marine, medical, electronics/electrical, […]

Read More

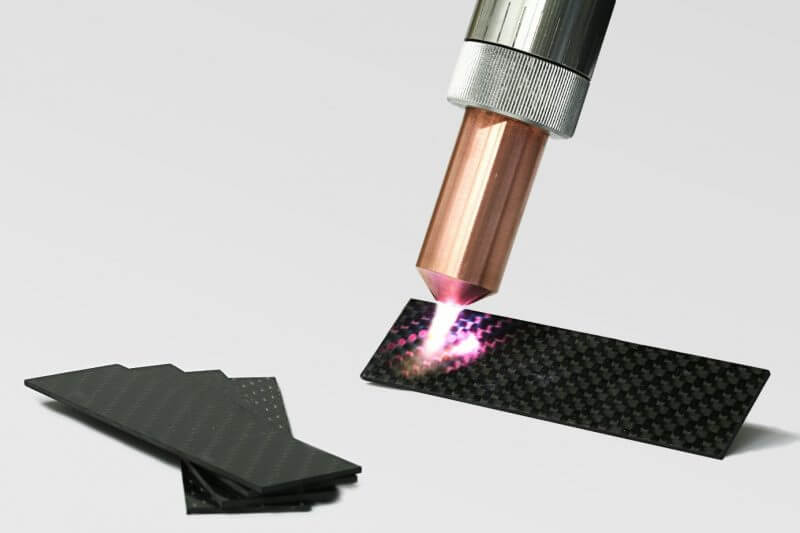

Plasma surface treatment for bonding composites

The bonding with adhesives of plastics to metals is an application which is growing. A typical example is the bonding of composite materials (carbon fiber, CFRP) and aluminium (Al) materials in the automotive sector. Various adhesives can meet the structural requirements of the bond. However, a polymer matrix of carbon fiber reinforced materials can have […]

Read More

Harley Davidson selects adhesives over mechanical fasteners

Odyssey Motorcycles used a carbon fibre epoxy composite for parts of on a Harley Davidson Super Sport Roadster (SSR). The French manufacturer used the material to make up the bodywork, petrol and oil tanks of the custom made motorbike, but then faced challenges around how to join it with the rest of the structure. It […]

Read More

Araldite adhesives bond racing car wing

Araldite® adhesives have been selected by Norma Auto Concept Engineering to bond the components of a rear wing for a prototype sports car. Founded in 1984 by Norbert Santos and Marc Doucet, whose names make up the brand name ‘Norma’ Auto Concept Engineering, the French-based business manufactures prototype vehicles for a range of racing, endurance […]

Read More

Araldite 2015 specified in motor cruiser construction

Araldite 2015 has been exclusively specified in the construction of the Neptys First Life 27, a semi rigid power boat made from a vinyl ester infusion. Because of its length, 8.5m, and speed, 50 knots plus, the Neptys First Life 27 is subject to impact and vibrations and needs an adhesive combination that could withstand […]

Read More