Category: medical

Wearables – adhesives and encapsulants for electronic textiles

Nature is a prestigious, peer-reviewed scientific journal known for publishing high-impact research across a broad range of scientific disciplines. Established in 1869, it is one of the world’s most influential scientific publications, covering fields such as biology, physics, chemistry, earth sciences, and more. Articles in Nature undergo rigorous peer review and are often groundbreaking, contributing […]

Read More

Very low extractables medical device adhesive withstands cleaning and sterilisation

Dymax 1045-M medical device adhesive was specifically formulated for the assembly of glass pre-fillable syringes, pen injectors, auto injectors, wearable injectors, and single-use devices. This very low extractables adhesive provides strong bonds that withstand the harsh cleaning and sterilisation processes pre-filled syringes undergo. Dymax 1045-M is also optimised to cure with LED UV light, providing […]

Read More

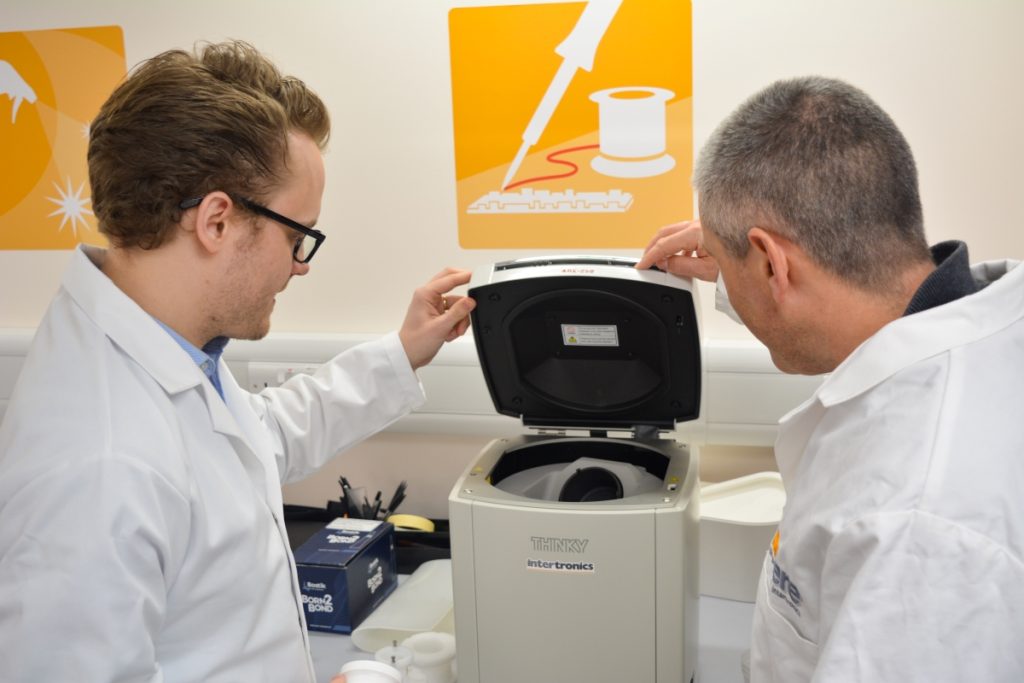

Accurate, repeatable mixers in scientific research

In the scientific community, particularly in universities, THINKY Mixers are becoming more prominent as a way to mix challenging liquids, pastes, and powders in research into nanotechnology, batteries, electronics, pharmaceuticals, and many more applications. A simple Google Patents search for “THINKY” demonstrates the huge number of technology and scientific breakthroughs that relied on the abilities […]

Read More

Fluorescence in adhesives and coatings

I saw a newsletter article which said that fluorescent animals are much more common than previously thought. Researchers who studied 125 mammal species, including cats, bats, polar bears and wombats (pictured), found that all of them showed some form of fluorescence, and that 86% had fur which actually glowed under UV light. This picture is […]

Read More

Bonding specialist medical device plastics

Medical device manufacturers are increasingly turning to specialist plastics formulated to resist harsh chemicals and survive environmental end use conditions such as sterilisation. However, the properties that allow these materials to withstand such conditions can also make them difficult to bond with adhesives. Here Kevin Brownsill, our Head of Technical: Learning and Development, shares guidance […]

Read More

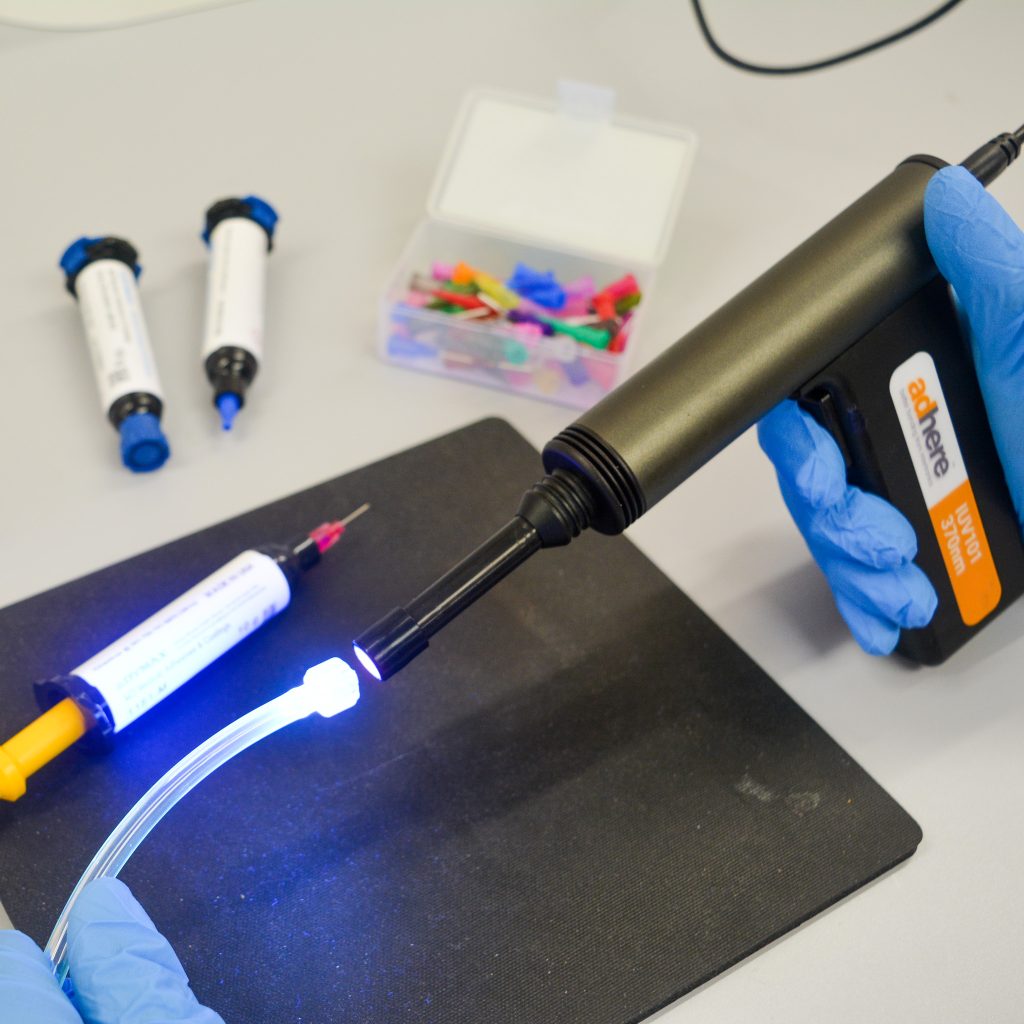

LED UV adhesive evaluation kit for medical device assembly

The IUV101 Medical Kit contains everything a manufacturer needs to start working with UV curing adhesive technology for medical device bonding, including three widely used adhesives in 10 ml syringes, alongside the IUV101 LED UV Spot Lamp for Handheld UV Light Curing. This device has a powerful 2,000 mW/cm2 light intensity, which users can focus on […]

Read More

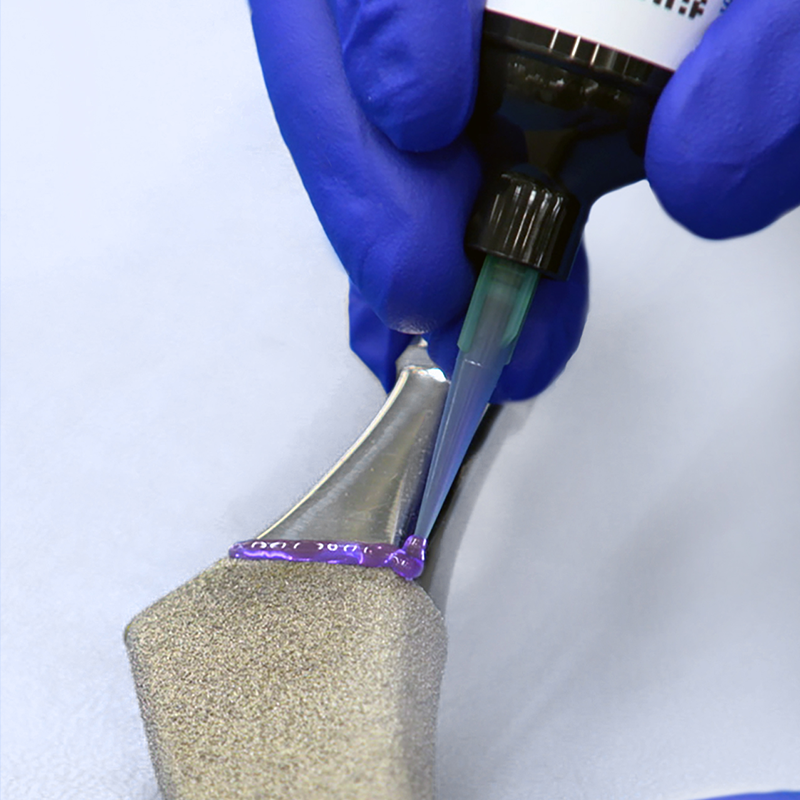

Masking orthopaedic implants effectively

Approximately 200,000 people receive hip or knee replacements in England and Wales every year, and these are typically highly effective. Research from the University of Bristol found that eight out of ten knee implants and six out of ten hip replacements last up to 25 years. To ensure long term success, orthopaedic implants must be […]

Read More

RFID tracking on surgical instruments

British surgeons are getting rather slapdash, according to The Knowledge. The number of “foreign objects” left inside patients after operations hit a record 291 in the year from 2021 to 2022, up from 156 two decades earlier. Swabs and gauzes are the most common items sewn up in patients, but scalpels and drill bits have […]

Read More

Electronics Industry Awards – we are finalists

A bit of excitement around here as we have been listed as finalists in the Medical Product of the Year category at the 2022 Electronics Industry Awards. We have been recognised for releasing Dymax’ 2000-MW series of medical device materials – a range of medical wearable adhesives and encapsulants which help adapt wearables devices to […]

Read More

Best cyanoacrylate adhesive for medical device assembly

For a medical device assembly adhesive which also provides the benefits of cyanoacrylate adhesive technology (e.g. single part, fast cure), we recommend you look at Born2Bond Light Lock. Light Lock passes ISO 10993 testing and is also a UV hybrid cyanoacrylate. The UV light curing aspect of Light Lock is useful for a bondline which […]

Read More

Article: New applications for light curable adhesives in medtech

The latest issue of Med-Tech Innovation News is out, and we are delighted to have an article published in it. Seeing the light: New applications for light curable adhesives in medtech discusses some of the latest formulations of UV curing adhesives used for assembling wearable medical devices, as well as some ideas on adhesives which […]

Read More

Industry-first adhesives for skin contact wearables

The Dymax 2000-MW series is a range of medical wearable adhesives and encapsulants which help adapt your wearables devices to industry trends and customer requirements. These materials are the first biocompatible, light-curable adhesive product line to be specifically formulated without common skin irritants and materials of concern for medical wearable and electronics applications. All adhesives […]

Read More

White Paper: Designing in light curing adhesives – a holistic approach to adhesives in medical device assembly

UV curable adhesives grant significant manufacturing productivity benefits, curing in seconds, “on-demand” when exposed to UV light. With grades certified to ISO 10993 and USP Class VI stands available, they are also well-matched to the manufacture of medical devices. To fully realise the potential that this adhesive technology can bring, it is necessary to take […]

Read More

Autoclave resistant medical device adhesive

Dymax MD® 1040-M is a new, versatile autoclave resistant medical device adhesive, coating, and encapsulant. Resistant to numerous cycles of sterilisation, Dymax 1040-M is suitable for consideration in a range of medical devices and surgical tools. This light curable material cures in seconds on exposure to UV light, and contains no solvents, to deliver a […]

Read More

Case study: increasing product design opportunities with Born2Bond Ultra HV CA

As consumers increasingly prefer smaller, more portable, wearable electronic devices, assembling the intricate components can prove challenging. This challenge is further compounded when considering skin contact material requirements and the bonding issues these materials can pose. Fortunately for a wearable electronic device manufacturer, our Born2Bond™ Ultra HV was able to address their bonding challenges while increasing their […]

Read More

Designing-In Light Curing Adhesives for Medical Device Assembly

Will you be at the Med-Tech Innovation Expo this year? The show, which runs from 28-29 September 2021 at the NEC in Birmingham, will feature a short seminar from our Managing Director, Peter Swanson. Designing-in Light Curing Adhesives for Medical Device Assembly will present an overview of UV and visible light curing adhesives and what […]

Read More

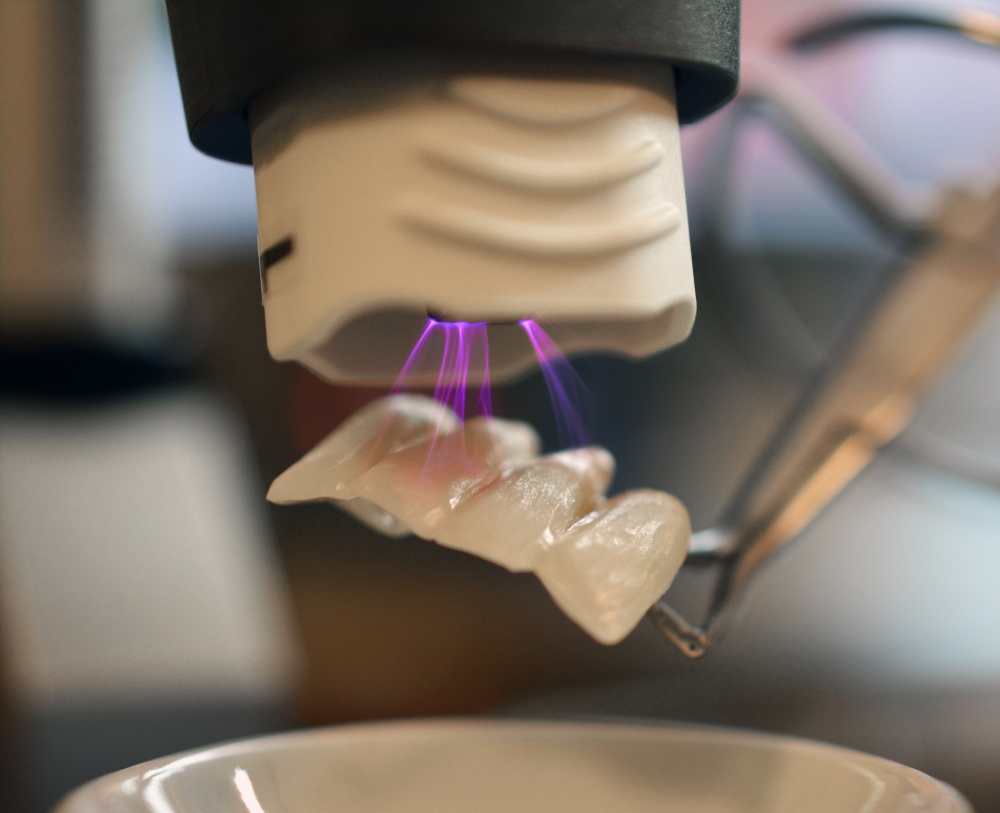

Article: plasma aids dental bonding

Eureka is a very highly regarded engineering magazine, so we were excited to see a two-page spread in the latest issue given over to our article Plasma Aids Dental Bonding. See page 32 to read how cold atmospheric plasma technology delivers benefits in dental labs. It features the PiezoBrush PZ3, the world’s smallest, highly effective […]

Read More

Plasma surface treatment in dental applications offers efficiency and better results

Plasma surface treatment technology is well established in many manufacturing industries including medical devices, electronics, and automotive. In dental technology, several use cases have been developed, researched, and established to help dental technicians perform tasks more efficiently and achieve better results for patients. Plasma can initiate several physical and chemical processes that both clean and […]

Read More

Seven considerations in medical device design

A great article in Med-Tech Innovation News lists seven considerations for medical device design; it was written by Dan Purvis of Velentium, a company specialising in the design and manufacturing of therapeutic and diagnostic active medical devices. It’s worth reading the whole thing, but consideration number 5 caught our eye: Design with manufacturing in mind […]

Read More

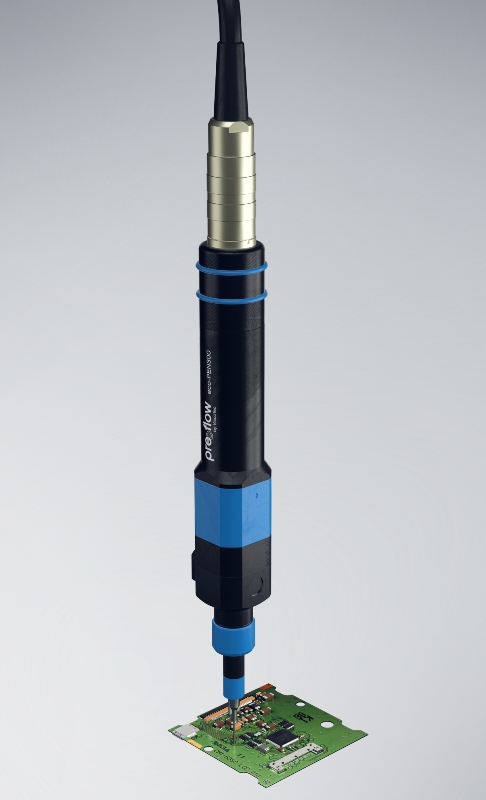

Accurate, precise dispensing for wearable technology

The comfort, flexibility and connectivity of wearables have been made possible through progress in sensor technology, power management and transmitter technology; these advances in wearable technology require improvements to the production process. One important part of the assembly process is the dispensing of materials like adhesives, silicones, thermally and electrically conductive materials and greases. Dispensing […]

Read More

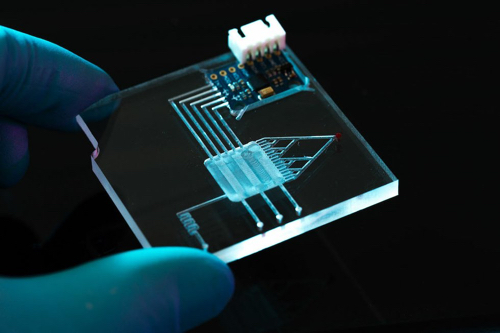

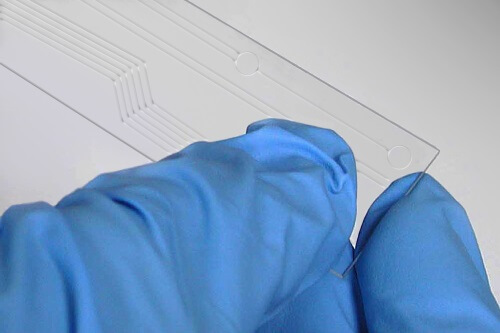

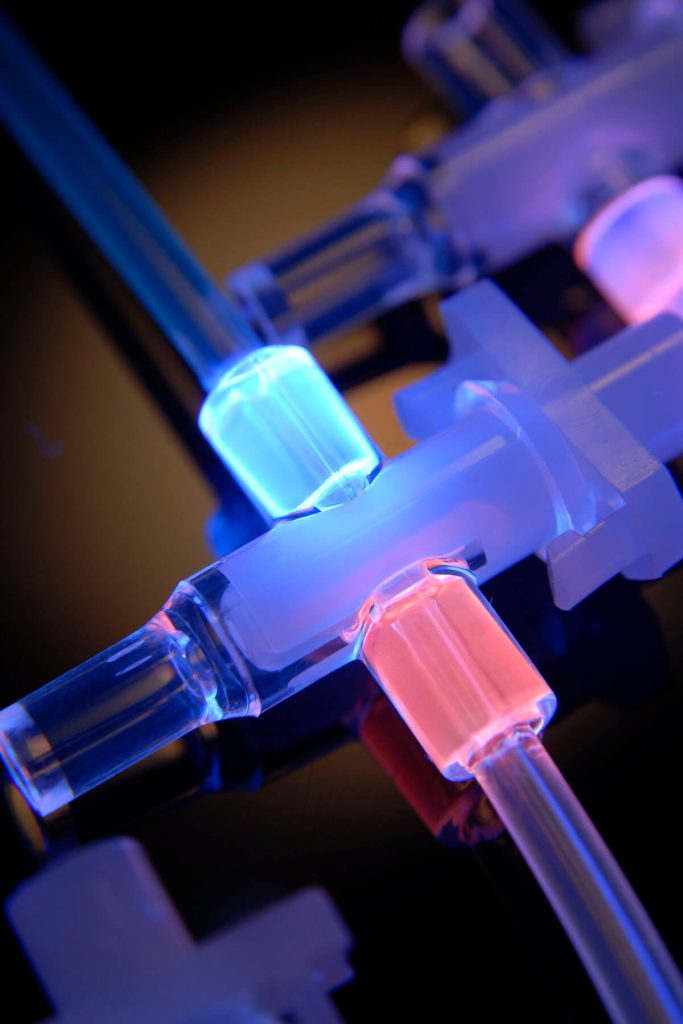

How to bond COC/COP film laminates

Dymax MD® 1172-M-UR is an LED UV and broad-spectrum light-curable adhesive for bonding COC/COP film laminates and other difficult-to-bond-to plastics used in the assembly of in-vitro diagnostics (IVD), Lab-on-a-chip (LOC), and other point-of-care medical devices. This adhesive may also be of interest to manufacturers involved with the design of COVID-19 rapid diagnostic applications. The adhesive […]

Read More

Medical-grade ISO 10993 silicone adhesive for bonding silicones and textiles

Wacker’s SILPURAN 4200® medical-grade silicone adhesive is a single-part transparent, room temperature vulcanising (RTV) silicone adhesive that is suitable for bonding cured silicone parts and highly elastic bonding between silicone and textiles, such as in ventilation masks and respiratory bellows. Formulated with a new catalyst which does not use organotin compounds, SILPURAN 4200 is ISO […]

Read More

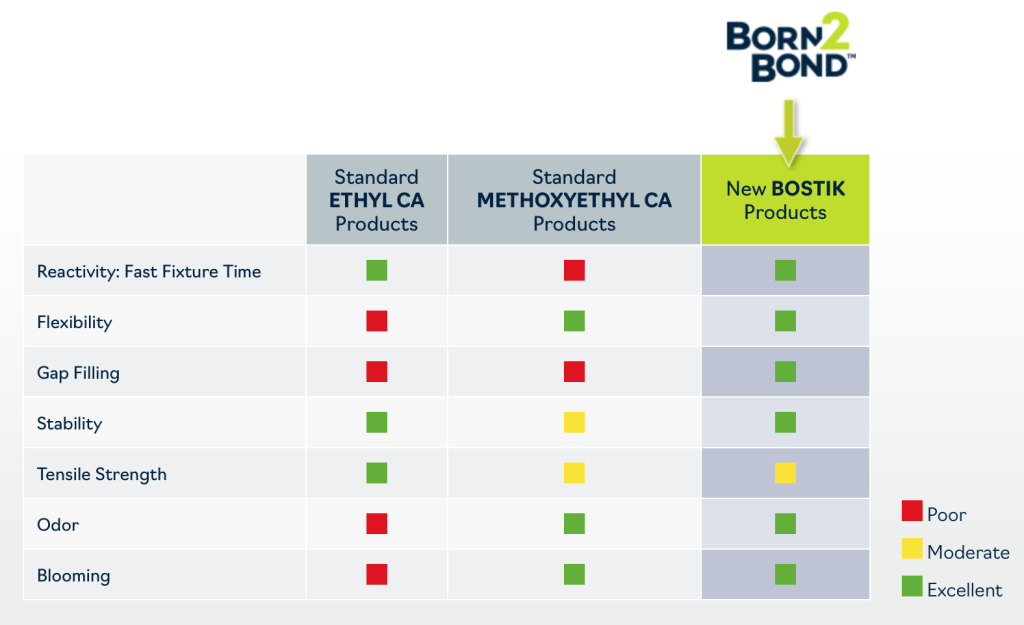

A big step forward in the technology of cyanoacrylate adhesives

Cyanoacrylate adhesives (CAs) have been around since the 1950s, and from the 1970s they have become a common household product. Today, manufacturers are increasingly using CAs and rely on them to bond plastics, metal, ceramic, rubber, wood and other substrates in many types of assemblies. They are unique in that they provide fast curing and […]

Read More

Adhesives, protective materials and equipment for medical device assembly

Our new brochure details the products we offer to those assembling medical devices. They include ISO 10993 adhesives and associated mixing, dispensing and curing equipment – all designed to help you achieve process reliability, repeatability and validation. As a medical device manufacturer, you need: Adhesives and protective material which bond to your substrates, withstand the […]

Read More

One of the many reasons we are open for business – we are essential

Many of our customers are Essential Businesses and must continue to operate and manufacture in support of infrastructure and other critical enterprises during these challenging times. The obvious sector is the manufacture of medical devices; for example, we supply adhesives to customers who are assembling and bonding needles for injections and products like diabetic testing […]

Read More

Medical Plastics News publishes UV curing article

The latest issue of Medical Plastics News (issue 51, November/December 2019) is out today. We are proud to be featured on page 17 with an article entitled All of the lights – an overview and some hints about using UV curing adhesives for medical device assembly. Read the complete issue, or click on the picture […]

Read More

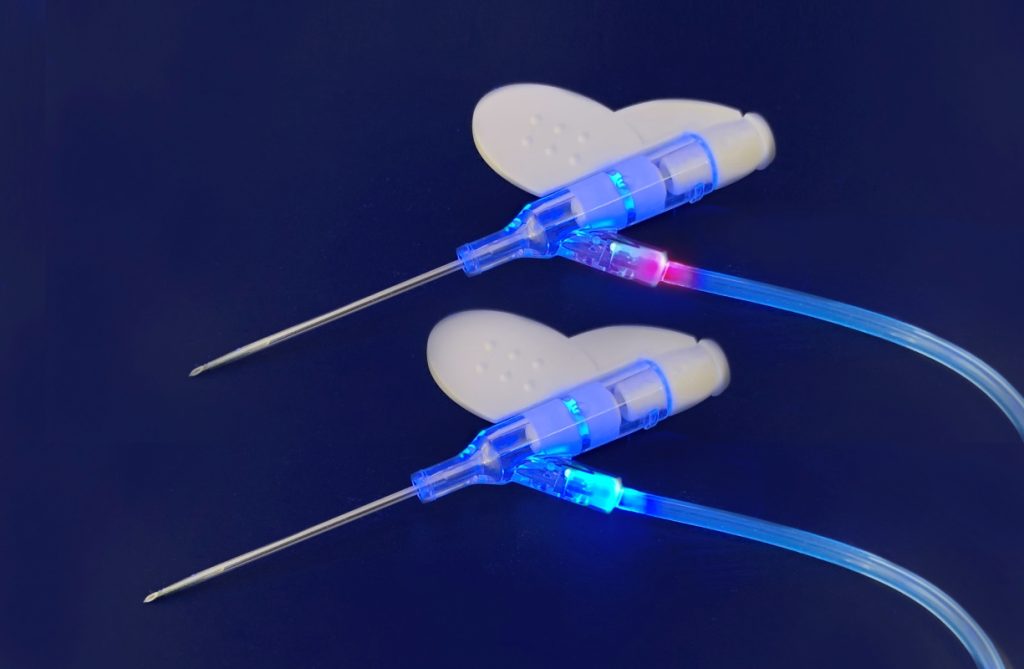

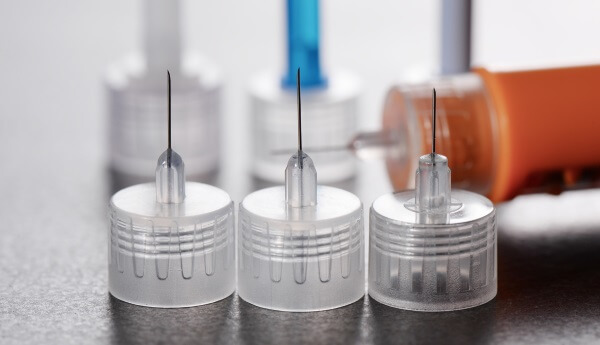

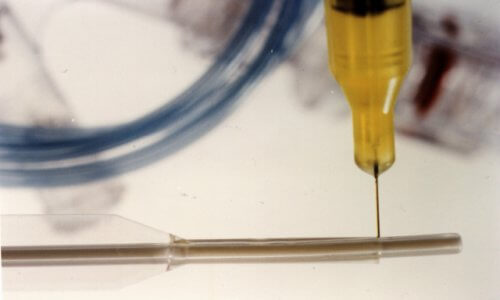

Next generation needle bonding adhesive

Our partners Dymax have recently introduced Dymax 1406-M, a next generation needle bonding adhesive for manufacturers looking to switch to UV LED curing in small gauge needle applications. It provides superior bonding performance on the reduced surface area of smaller cannulas, even after aging and sterilization, to reduce the possibility of cannula substrate failure. Optimized for […]

Read More

Wearable technology and patient mobility

Advances in wearable technology are coming thick and fast. Even that most conservative of investor, Warren Buffet, has seen fit to put his weight behind the wearable tech industry. With these advances comes multiple benefits, none more so than in the medical field. We all understand the idea of smart watches and other gizmos which […]

Read More

Challenging surface activation applications met by the PiezoBrush PZ2

The Relyon Plasma PiezoBrush® PZ2 has nozzle attachment options for surface activation across a wide range of applications. Treatment of metals, and smaller and more precise applications are now possible. The use of a variety of special gases enhance the possibilities of PDD (Piezoelectric Direct Discharge) on challenging substrates. Based on the direct, electric discharge at […]

Read More

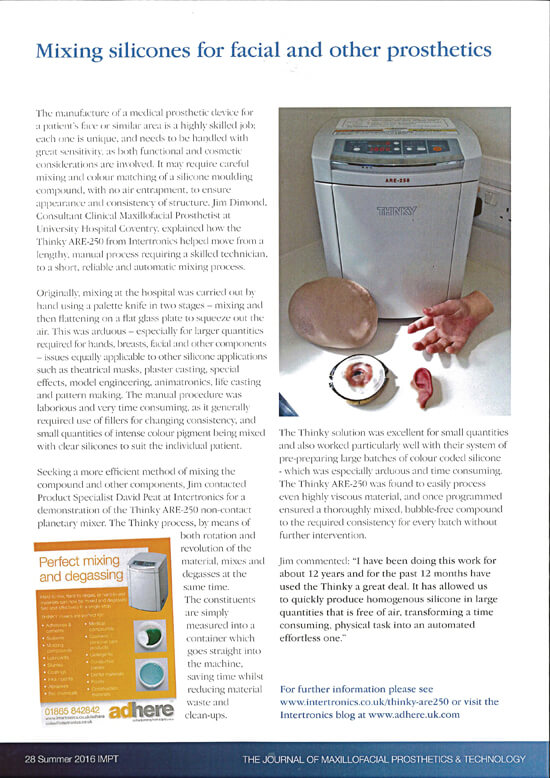

Mixing silicones for facial and other prosthetics – in the press

It’s great to see our Thinky ARE-250 Mixing and Degassing Machine feature in the latest edition of the Journal of the Institute of Maxillofacial Prosthetists and Technologists (IMPT). The piece describes how we worked with Jim Dimond, Consultant Clinical Maxillofacial Prosthetist at University Hospital Coventry to help him save time and improve the quality of their mixing process when mixing […]

Read More

Case study: preeflow volumetric adhesive dispensing helps ensure integrity of life-saving medical device

Our customer BPR Medical, based in Mansfield, Nottingham, is a perfect example of a small British company which combines expertise, creativity and entrepreneurialism to design, develop and manufacture world-beating products for export worldwide and use in the United Kingdom, for which it was rewarded in 2012 with a Queen’s Award for Enterprise: Innovation. As with […]

Read More

Case study: mixing silicones for facial and other prosthetics

The manufacture of a medical prosthetic device for a patient’s face or similar area is a highly skilled job; each one is unique, and needs to be handled with great sensitivity, as both functional and cosmetic considerations are involved. It may require careful mixing and colour matching of a silicone moulding compound, with no air […]

Read More

Epoxy adhesives & potting compounds for specialist applications

The new Polytec PT brochure offers information on specialist epoxy resin adhesives and potting compounds for electronics, electrical engineering, optical and medical industries. It details high strength optically transparent epoxies, including formulations with flexibility in the Shore A range. Medical device manufacturers will find products which are biocompatible and tested to USP Class VI. These materials […]

Read More

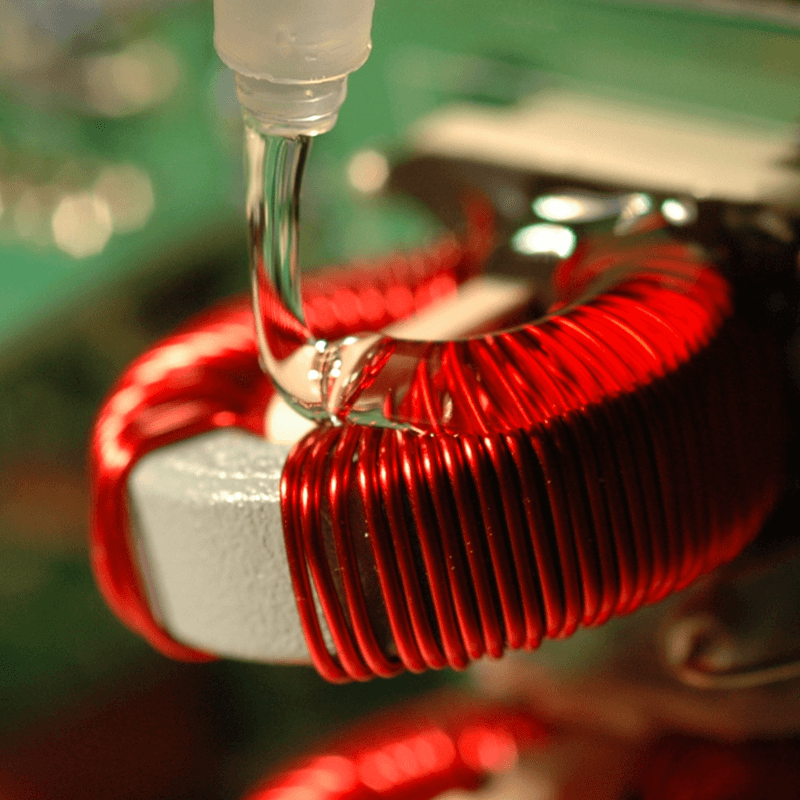

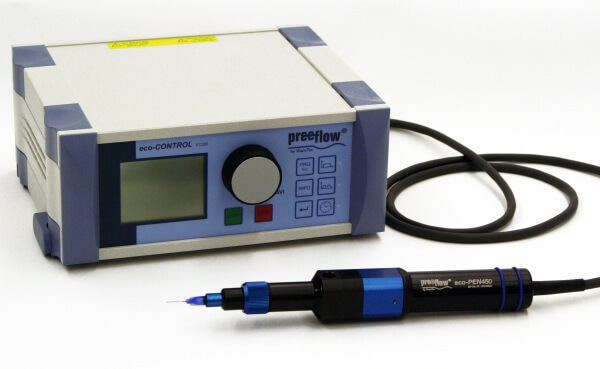

Repeatability, precision, reliability and accuracy in dispensing

The method of using a positive displacement technology for the dispensing or dosing of liquids can bring many benefits to those for whom repeatability, precision, reliability and accuracy are important. preeflow volumetric dispensing pumps have found applications in sectors such as electronics and semiconductor manufacturing, aerospace, medical device assembly and pharmaceuticals – from the application […]

Read More

Video: Adhesives, protective materials and processing equipment for medical device assembly

We offer materials and processing equipment to meet the bonding and assembly needs of medical device manufacturers. A range of ISO 10993 and USP Class VI materials are compatible with the substrates commonly used in the industry. The range comprises structural adhesives, coatings, sealants, form-in-place gaskets and temporary masks – all for medical device assembly. And mixing, […]

Read More

Medical device adhesive case study published in BP&R

Thank you to British Plastics and Rubber magazine, who feature one of our recent application stories regarding Brandon Medical in the latest issue. The company used one of our LED UV curing plastic bonding adhesives to save production time. Click on the image to open a copy of the article.

Read More

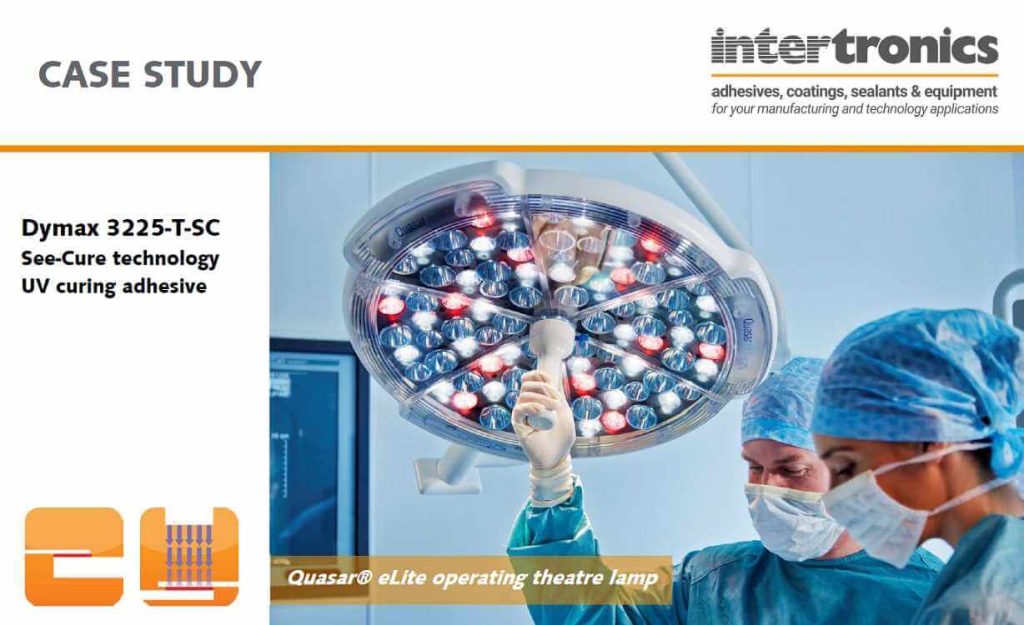

UV adhesive cures time problem for Brandon Medical

Extended curing times for adhesives can often create a bottleneck in the production process which can interrupt work flow. This was exactly the problem experienced by Brandon Medical Ltd. Technical Director Nigel Davill explained: “We had a problem bonding three polycarbonate lenses together to make the large front lens of our Quasar® eLite operating theatre […]

Read More

Adhesive offers excellent adhesion to COC/COP film laminates

Cyclic olefin polymers/copolymers (COP/COC) have become popular choices in the point-of-care device industry because of their high strength, hardness, low water absorption, and excellent biocompatibility. Dymax 1072-M MD® is a new UV/broad-spectrum-cured adhesive specifically designed for bonding COC/COP film laminates and other difficult-to-bond-to polymers. Designed to be optimised for curing with LED lamps, Dymax 1072-M will cure […]

Read More

Fluid pressure sensor with luer-lock connections for medical applications

The flowplus16 is a high precision fluid pressure monitor device (up to 16 bar) designed from concept to exactly fit medical device criteria by including the standardised Luer-Lock connector system and internally, a void free flow channel coated with a virtually inert FDA compliant elastomer. In particular, the universal single size Luer-Lock system enables equipment […]

Read More

New brochure – medical device assembly adhesives, protective materials and processing equipment

Our ISO 10993 and USP Class VI adhesives and protective materials – and associated dispensing and curing equipment – are the subject of a new brochure. The range has been built to help you achieve vital process reliability, repeatability and validation. Products featured include DYMAX medical grade adhesives, coatings and masking materials, Opti-tec epoxy adhesives, […]

Read More

Technical article: Customized Masking Solutions

We have just added a new white paper to the Technical Bulletins, White Papers & Articles page on our website entitled – Customized Masking Solutions Don’t Require Customized Masks. Are Your Masking Solutions Failing? The article, written by Virginia Read of Dymax Corporation, discusses masking with conventional methods, the challenges associated with complex design configurations and the need […]

Read More

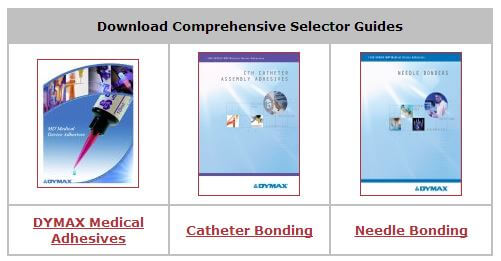

Medical device adhesive selector guides help simplify product selection

We have recently placed updated selector guides on our website for Dymax Medical Device Adhesives. These guides provide comprehensive information on Dymax products and are intended to help device manufacturers choose the appropriate adhesive together with compatible dispensing and curing equipment for their specific requirement. The two guides include details of adhesives for Needle Bonding and […]

Read More

Catheter adhesive – how do you know it’s cured?

Dymax 214-CTH-UR-SC adhesive has been formulated to incorporate both Ultra-Red and See-Cure technologies. Designed to be used in catheter assembly and other medical device assembly applications, it offers excellent bond strength to a number of plastics including PEBA and Nylon 12. Dymax 214-CTH-UR-SC is blue in colour when in its uncured state, enabling easy verification […]

Read More

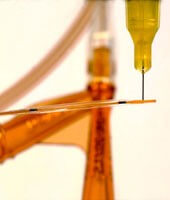

Needle bonding adhesives fast cure with LED light

Dymax has released a new range of LED UV and visible light curable needle bonding adhesives. These adhesives are ISO 10993 approved and have passed testing to support short-term (<29 days) implantation or single use disposable device applications. Dymax 1400 series needle bonding adhesives are solvent free, single component and fluoresce for inline testing and […]

Read More

Adhesive for medical device assembly cures in seconds – ISO 10993

If you are looking for a medical grade adhesive which adheres to PC, PS, PU, ABS, and stainless steel, DYMAX Ultra-Red™ 1193M-SV05-UR could be your answer. Designed for the rapid application and bonding of plastics and metals typically used in the manufacture of syringes and needles, DYMAX Ultra-Red™ 1193M-SV05-UR is an ISO 10993 tested, moisture-resistant, multi-purpose medical-device adhesive which cures quickly upon exposure to UV and/or […]

Read More

See us at this medical device design and manufacturing show

Med-Tech Innovation Expo takes place 10-11 April 2013 at the Ricoh Arena, Coventry. Med-Tech Innovation Expo is 100% dedicated to medical device design and manufacturing and is at the very heart of the industry – and we are on stand 6! We will be focusing on adhesives and adhesive systems for medical device manufacture – how to address […]

Read More

Multi-purpose fluorescing medical device adhesive for plastic and metals

DYMAX Ultra-Red™ 1193M-SV05-UR is a ISO 10993 tested, medical grade adhesive designed for rapid dispense and the bonding of plastics and metals. Typically used in the manufacture of medical syringes and needles, the adhesive is multi-purpose and can be used across a range of applications. Bondable substrates include PC, PU, PS, ABS and stainless steel. It cures upon […]

Read More

Medical device bonding – adhesives for needles, cannula, catheters and guidewires

Two new selector guides are available, detailing our extensive range of DYMAX adhesives for bonding needles and catheters. The guides contain technical details about the wide range of adhesives available for these specific applications, as well as curing and dispensing information, and joint design advice. The selector guides are available from us in hard copy, […]

Read More

We are exhibiting at Mediplas 2012 – medical device plastics and assembly

Next month, September 25-26, we will be exhibiting at Mediplas at the NEC, Birmingham. Mediplas is a new focused event for the highly specialised area of manufacturing plastic parts for the medical industry. The exhibition will cover all areas of the medical plastics supply chain – including design and prototyping, materials, clean room machinery (extrusion and […]

Read More

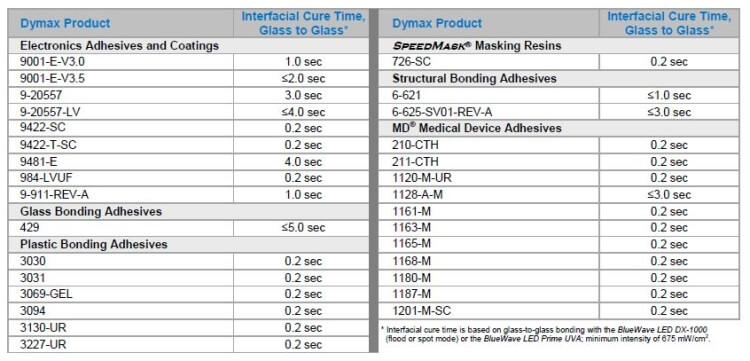

Adhesives for curing with LED UV lamps

With the combination of expertise in LED light curing equipment technology and adhesive formulation, our partners DYMAX have an ever-growing list of adhesive and coating formulations optimised to cure with our BlueWave LED curing lamps. These include applications in electronics, glass bonding, plastic bonding, temporary masking, structural bonding and medical device manufacturing.

Read More

Autoclavable adhesive/encapsulant for optical and medical applications with USP Class VI

Polytec EP 630 is a two-part epoxy adhesive which provides excellent high temperature, chemical, electrical and moisture resistance. Especially designed for applications in the semiconductor, medical, hybrid, piezo, fibre optics, HV and UHV applications, it has an excellent adhesion to silicon, glass, metal, ceramic, ferrite and most plastics and can be used as a low viscosity adhesive, […]

Read More

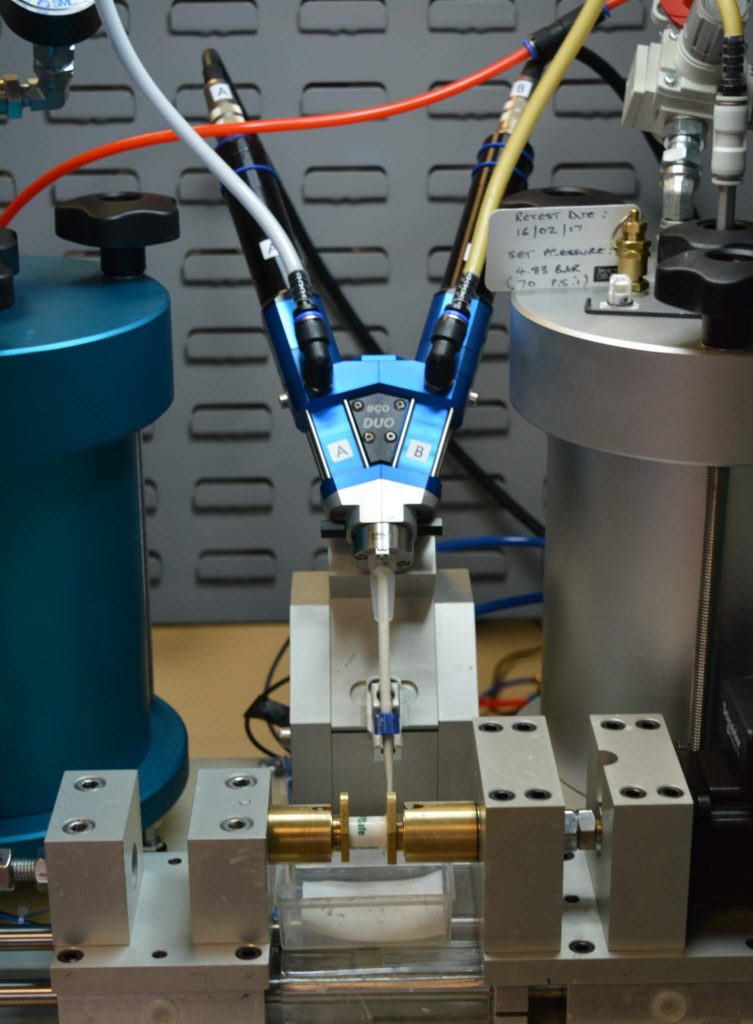

Precision metering, mixing and dispensing of two part adhesive and resin systems

The preeflow® eco-DUO450 is a two-component precision volumetric, positive displacement, dosing/mixing/dispensing system that gives you accuracy and repeatability. The preeflow eco-DUO450 uses the precision dispensing technology of the preeflow eco-PEN – by integrating two eco-PENS through a manifold and a static mixing nozzle, and provides extremely precise metering, mixing and dispensing of critical two-part materials like epoxies and silicones. The preeflow® eco-DUO450 can dispense as […]

Read More

Electrically conductive, silver-loaded adhesives

We are now able to offer a range of high technology, electrically conductive adhesives. The products are two-part and single-part epoxy systems designed for electronic interconnects in a wide range of applications, including hybrid electronic assembly and solder replacement. These adhesives are primarily silver-loaded. Polytec PT Electrically Conductive Adhesives are available in a wide range of […]

Read More

Electrically and thermally conductive adhesives – new products!

We are very pleased to announce that we have signed a distribution agreement with expert German adhesives manufacturer, Polytec PT. Polytec PT offers a range of high technology adhesive products for micro-electronics, hybrid circuits, chip-on-board (COB), LEDs, component manufacture, displays, flexible circuitry, shielding, medical devices and optics/opto-electronics. The range consists of: Electrically conductive adhesives Thermally […]

Read More

preeflow eco-PEN 450 extends the capability and accuracy of volumetric dispensing

We recently introduced the preeflow® eco-PEN 450 from ViscoTec, which not only offers a greater capacity for high accuracy and highly repeatable volumetric dispensing – it also addresses the needs of a wide range of low to medium viscosity applications. These include oils and fats, colour mixes, silicones, sealing compounds, adhesives and even abrasive media, […]

Read More

Building Better Bonds Using Light-Cure Adhesives in Medical Device Manufacture

If you are manufacturing medical devices, we want to recommend to you a feature article by Nadine Blaesing from our partners DYMAX. Building Better Bonds Using Light-Cure Adhesives The use of light-cure adhesives can optimise product assembly and reduce material waste, thereby achieving cost savings in the production process without affecting quality Medical device manufacturers have […]

Read More

Optically Clear Epoxies, Potting Compounds and Adhesives

The Opti-tec™ range of optical adhesives and encapsulant continues to develop, and includes many with high optical clarity or other special properties related to specific optical applications such as fibre-optic termination or optical potting and encapsulation. Some of the range have passed ISO 10993 testing for medical device manufacture or are Telcordia GR-326-CORE compliant. Specialist […]

Read More

We will be at the MEDTEC 2011 show this week

This week, we will exhibiting at MEDTEC UK in April (6-7th) at the NEC. Along with UV, cyanoacrylate and epoxy adhesives, we will showing UV curing equipment, dispensing, application and mixing equipment. This will include the THINKY mixing range, a Fisnar benchtop dispensing robot and a DYMAX LED Prime UVA spot curing lamp demonstrating the fast curing of medical grade, ISO […]

Read More

Catheter adhesive cures tack free in less than one second with LED lamp

Dymax 210-CTH, a new MD® Medical Device Adhesive, is a tack-free, LED-curable adhesive formulated for fast, on-demand cure with the Dymax BlueWave MX-150 LED UV spot curing lamp. This adhesive is designed for rapid bonding of a wide variety of plastics typically used in the manufacture of catheters. Bondable substrates include PC, PU, ABS, and […]

Read More

New magazine and website about medical device technology

We welcome the new venture from some old friends, Colin and Annie. Med-Tech Innovation is a brand new media platform for the UK and Irish medical device research, design and manufacturing community. There has never been one information resource that provides dedicated technical, product, industry, academic and association content for and about the UK and […]

Read More

Seeing Red – For Accurate Bondline Inspections

An impressive new fluorescing adhesive technology, brought to you by our sales partner Dymax, will have you all “seeing red” to improve quality and authentication. The advantages of Ultra-Red™ technology are based on the fact that many plastics naturally fluoresce blue under UV blacklight – this minimises the inspection advantages of using conventional blue-fluorescing adhesives […]

Read More

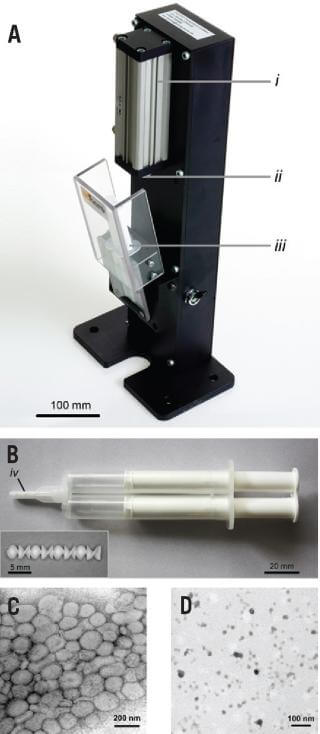

Special dispenser for disposable dual barrel syringes

On occasion, we are asked to help customers with special dispensing requirements – something which can’t be done with off-the-shelf equipment. The Nuffield Department of Clinical Laboratory Sciences at the John Radcliffe Hospital, Oxford were working on the generation of nonviral gene therapy formulations. They wanted a reproducible method to mix the materials from twin […]

Read More

Latest selector guide for medical device adhesives

Recently, we updated our website with an enhanced version of the comprehensive Dymax Selector Guide on MD® Adhesives for Medical Device Assembly. This valuable tool contains a number of charts intended to help R&D engineers and product designers choose the appropriate adhesive for their application. All Dymax MD® Adhesives are biocompatibility tested in accordance with […]

Read More

Seeing red

We have just updated our DYMAX Medical Device UV Curing Adhesives webpage to offer the latest version of their selector guide – it’s a download from there. Dymax are announcing some really exciting developments in this field (more to come soon!). Ultra-Red™ Fluorescing Technology is one. Once assembled and cured, DYMAX UV curable adhesives are […]

Read More

How many substrates are in your medical device assembly?

That is the question which was asked recently by our Sales Partners Dymax, in an advertisement introducing a new product in their range of adhesives for disposable medical devices, Dymax MD® 1161-M. The text is possibly too small to read in this reproduction for the blog, but it goes like this: Design engineers strive to […]

Read More