Batteries and Fuel Cells

High performance, durable, efficient batteries and fuel cells need high performance adhesive materials and processes

With a number of the UK’s leading battery developers and manufacturers as part of our customer base, we have the application understanding to help you with adhesive materials and equipment for tasks including cell module assembly, thermal management, slurry mixing, and battery pack assembly.

- Adhesives

- Thermally conductive adhesives

- Gasketing materials

- Potting materials

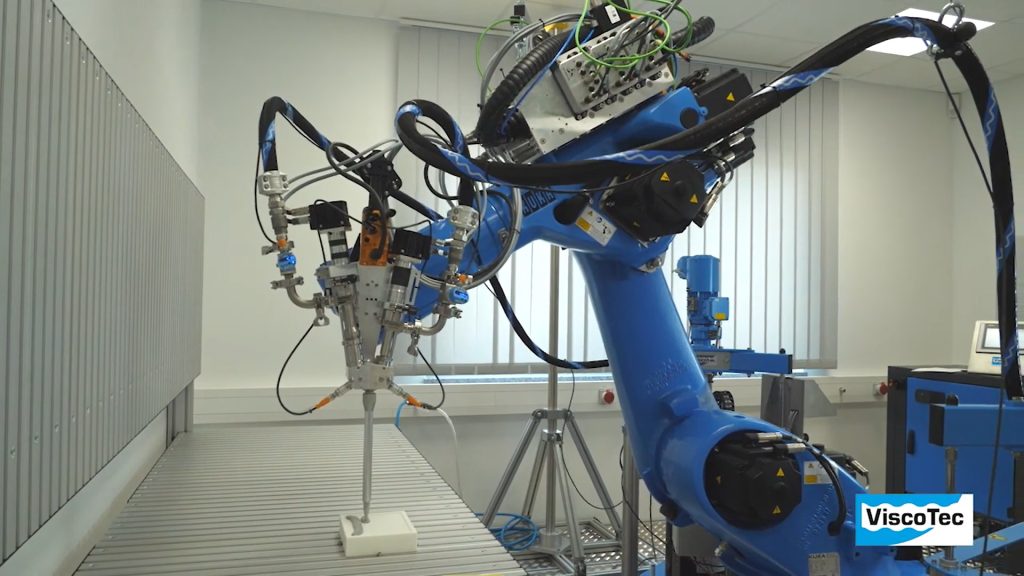

- Dispensing valves, robots, and automation equipment

- Mixers

- Surface treatment systems

- UV light curing equipment

- Other adhesive, sealant, potting, and masking materials for a wide range of applications

A focused, synergistic range of products

We can help you with:

Slurry Mixing

Our THINKY planetary centrifugal mixers offer straight-forward, repeatable mixing processes for battery slurries, enabling a consistent, even mix and dispersion of electrode particles in seconds to minutes.

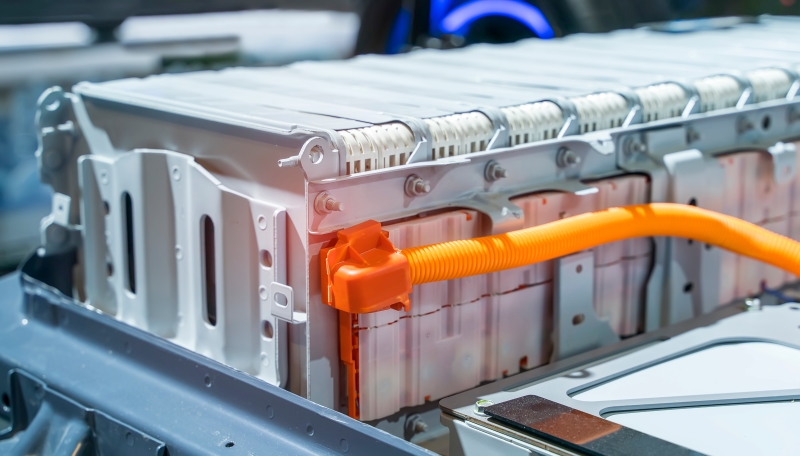

Battery Pack Assembly

For electric vehicle battery potting and bonding, we offer purpose-designed adhesives, including a light-curable adhesive with thermal shock resistance which retains strength under high temperature and high humidity environments.

Thermal Management

Facilitating heat dissipation away from the cell increases its operational efficiency and prolongs its service life.

We can help you find a material that meets your requirements in terms of thermal conductivity, chemical resistance, vibration damping, structural performance, and dielectric strength. Our selection of silicone and epoxy thermally conductive adhesives and potting compounds have been designed with battery production in mind.

Electric and hybrid vehicle parts such as power electronics, converters, motors, and control units can also be bonded, sealed, and/or encapsulated with thermally conductive materials to improve durability and energy efficiency.

Alongside these materials, we offer matched mixing, dispensing, curing, surface treatment and automation equipment so that you can implement the whole adhesive process with confidence.

Fuel Cell Assembly

When creating a seal between your bipolar plates and membrane electrode assemblies, the gasket needs to provide a tight seal that lasts the full lifetime of the fuel cell while protecting against moisture, vibration, oxidation, and chemicals. It must have resistance to temperature changes, aging, and the radicals and intermediates inherent in fuel cell composition.

A gasket material that is inert to the catalyst and membrane will maximise the lifetime of the system. We have both silicone and epoxy materials suitable for this application, as well as the equipment to dispense gaskets accurately and precisely.

We have several customers who manufacture fuel cells and rely on our products to perform to these requirements, alongside our results-focused technical support and expertise with ongoing supply chain support.

Comprehensive knowledge, seamless support

We will advise you on suitable adhesives and associated dispensing and curing methods for your products and processes. We will help you evaluate these materials and equipment and provide ongoing technical and supply chain support throughout the lifetime of your production.

Proven success in the battery and fuel cell industries

Let’s start by talking about your application

01865 842842

info@intertronics.co.uk

Get in touch and we’ll respond within the business day