Robots: the opportunities… or the risks?

The application of adhesives, potting compounds, encapsulants or other liquids, fluids or pastes, is something that can often be readily automated with a dispensing robot. Manufacturers that are still performing these processes manually may be concerned about the potential risks of transforming their processes with automation. On the other hand, the potential rewards are great — including improved consistency, speed, and accuracy that lead to gains in productivity.

One of the historic barriers to automation is the perceived risk of investing in new equipment. After all, if a manual process is working well then why upset the applecart? Nevertheless, recent events like Covid, the war in Ukraine, and Brexit have impacted how we do business, and how industry perceives risk.

Supply chain challenges are making it more difficult to source components, and the risks associated with long global supply chains mean that many manufacturers are reshoring their manufacturing operations. Businesses are also increasing their local supplier base. According to a survey by Make UK, three quarters of companies have increased the number of British suppliers they are using.

The success of these reshoring programmes depends on the availability of labour and, at present, the UK is facing a high number of job vacancies. If manufacturers are unable to recruit the people they need to reshore manual processes, then alternative methods of production become more attractive.

Following the events of the last few years, manufacturers are now more likely to see the opportunities of robots, rather than the risks. As Henry Ford once said, “If you need a machine and don’t buy it, you pay for it without getting it.”

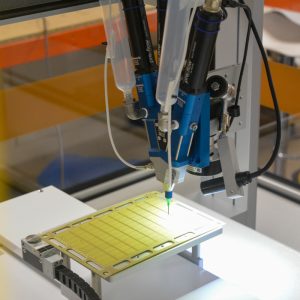

With these factors in mind, the application of adhesives and other materials is a prime candidate for automation. A dispensing robot can apply materials with positional accuracy and precise quantities, and repeat that all day long. The output is often faster than a manual process and, sometimes, robots can achieve results that are not possible for a human. For example, applying an even bead of gasketing around a complex profile is not manually feasible.

Investing in dispensing robots: what will I need?

If you are looking to invest in dispensing automation, there are four main components to the system. They are, first, the robot used to position and actuate the dispenser and, second, the dispenser (valve, pump, syringe or cartridge as well as the required controller and material reservoir) that is chosen to distribute the material. The third component you’ll need is the tooling used to hold the parts in place and, fourth, the enclosure — an important consideration for health and safety.

The specification and choice of the dispensing methodology (valve, pump, syringe, cartridge, etc) is quite complex and material dependent. By working with a reliable supplier that understands the intricacies of both the chemistry and the dispensing technology, manufacturers are more likely to invest in an optimal combination of technologies for their application — and get better results. Your supplier should also be able to integrate the dispenser with the robot and configure and customise the system with holding tools and fixtures, benches, and safety enclosures. The last piece of the puzzle is installation and training, to ensure that you are up and running right away, and that your team understands how to operate the equipment to get the best from it.

Reducing the risk

To help de-risk the investment further, check that the supplier has been validated by a third party. Do they have a number of case studies that show successful robot installations? At Intertronics, we offer customers the opportunity to visit our Technology Centre in Kidlington, Oxfordshire, where we can support with trials and tests to establish how the equipment will perform in your application.

In many cases, the upfront cost of dispensing robots is not as high as some manufacturers think — it might even be less than the Managing Director’s new car! At Intertronics, we often see our customers achieve a payback period of six months to a year.

With the UK lagging in its robot uptake, it’s time we focus on the rewards of robots: improved productivity, efficiency, output, quality, and flexibility. In applications like dispensing, which lend themselves so well to automation, manufacturers have a lot to gain and very little to lose.

Interested in how you can receive a good return on investment with a dispensing robot? View our worked example.

Categories: dispensing, productivity, robotics