Category: case study

Wearables – adhesives and encapsulants for electronic textiles

Nature is a prestigious, peer-reviewed scientific journal known for publishing high-impact research across a broad range of scientific disciplines. Established in 1869, it is one of the world’s most influential scientific publications, covering fields such as biology, physics, chemistry, earth sciences, and more. Articles in Nature undergo rigorous peer review and are often groundbreaking, contributing […]

Read More

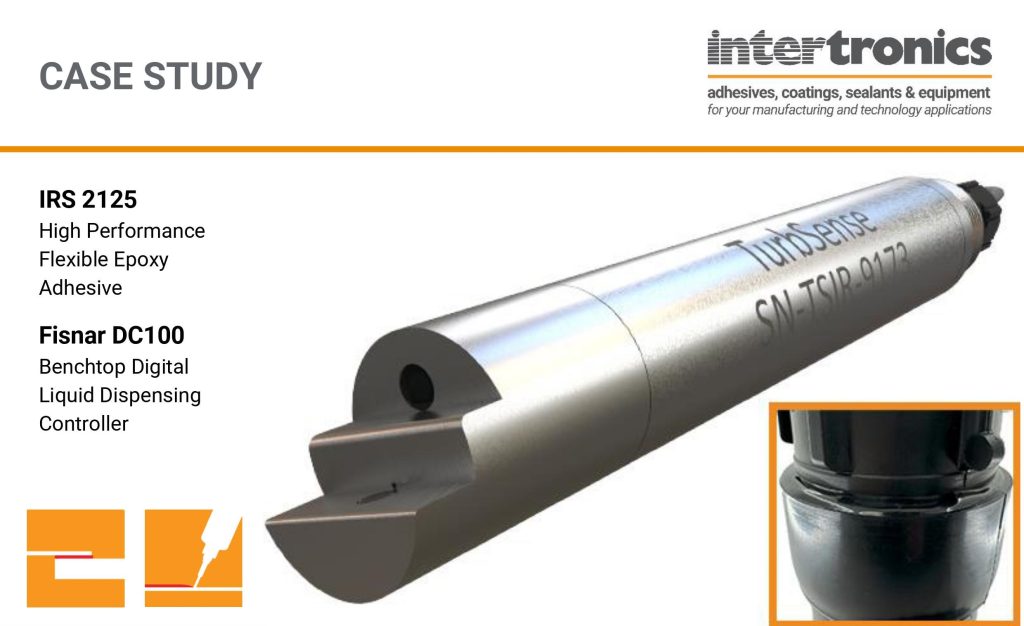

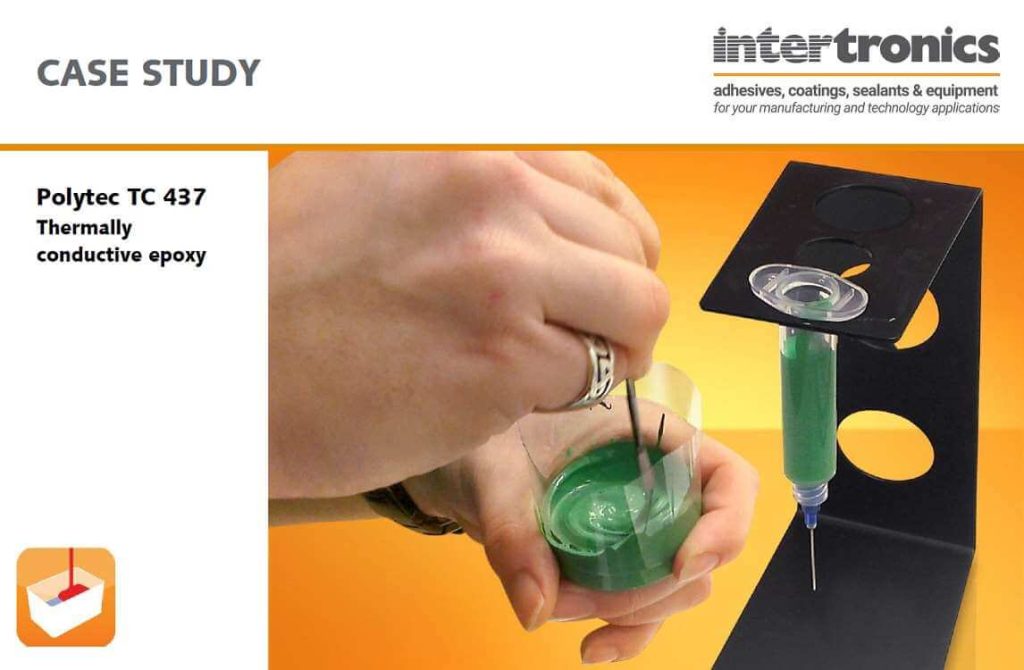

Case study: flexible epoxy drives performance

We are supplying Process Instruments (Pi), a water analyser instrument manufacturer, with our IRS 2125 High Performance Flexible Epoxy Adhesive. This versatile adhesive offered performance benefits as a thread locker on flow cells and an IP68 rated sealant on sensors. Pi manufactures and supplies water analyser instrument solutions that can reliably, continuously, and accurately measure […]

Read More

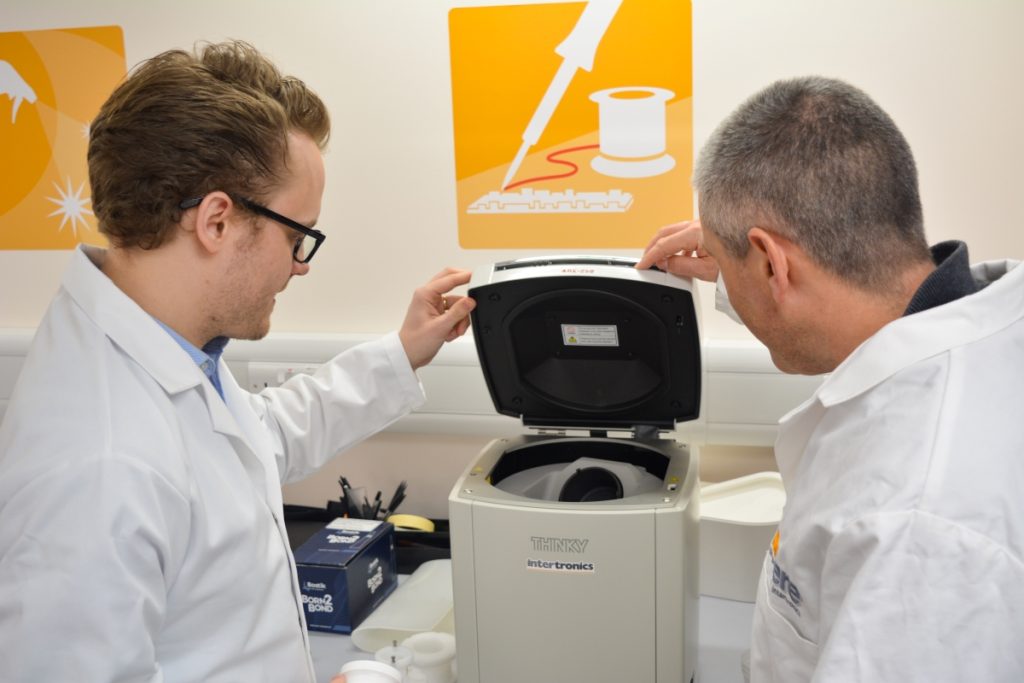

Accurate, repeatable mixers in scientific research

In the scientific community, particularly in universities, THINKY Mixers are becoming more prominent as a way to mix challenging liquids, pastes, and powders in research into nanotechnology, batteries, electronics, pharmaceuticals, and many more applications. A simple Google Patents search for “THINKY” demonstrates the huge number of technology and scientific breakthroughs that relied on the abilities […]

Read More

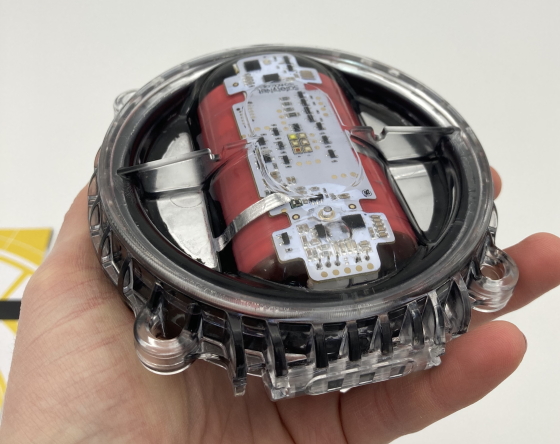

Case study: protecting rugged, outdoor work lights from the elements

Venta Global is a tier one supplier of lighting solutions to vehicle and machinery manufacturers, offering a complete service from custom design to delivery. It has made significant investment into new technology for its UK production facility in Hampshire that deskills processes to enable consistent and reliable results, removes inconsistencies due to operator variance, and […]

Read More

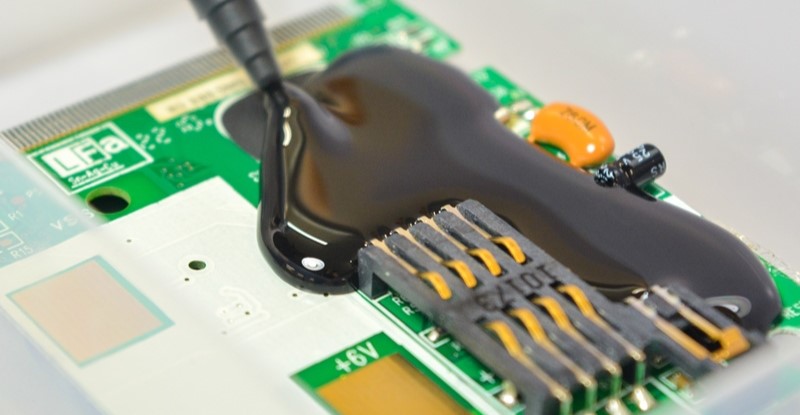

Three worked examples of potting PCB assemblies

Potting is a common method to protect PCB assemblies, which involves filling an enclosure with a liquid material to protect the board and its electrical components. Depending on your application’s needs, there are a wide range of potting compounds available in a variety of formulations, including low density/lightweight, flame retardant, flexible, optically clear, and thermally […]

Read More

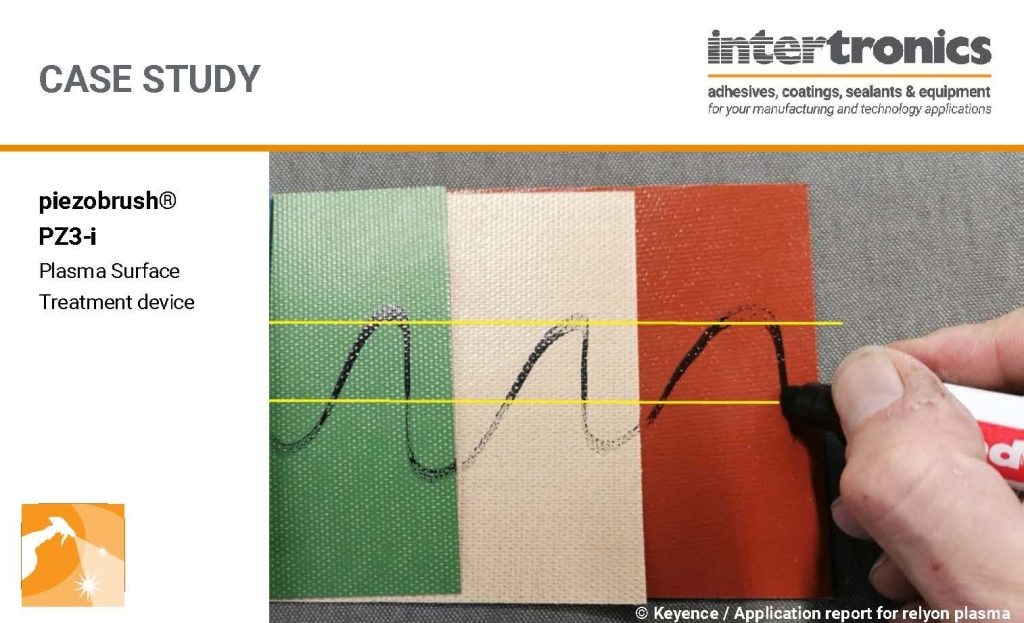

Case study: achieving reliable printing onto PTFE with plasma pre-treatment

Due to PTFE’s extremely low surface energy, it is difficult for materials to wet, and almost no materials or adhesives readily adhere to it. The commonly known brand name of PTFE-based composition is Teflon – yes, the non-stick stuff. However, plasma can be applied to alter the chemical groups on the surface, increase wettability and […]

Read More

Case study: potting a bespoke telematics system

Bulk Tainer Logistics provides bespoke transport services for the shipment of bulk liquid products globally, operating a fleet of 12,000 chemical, feed, and food grade tank containers. To optimise the performance of its fleet, the company wanted to fit its tanks with smart monitoring devices that tracked the movement of the tanks and the condition […]

Read More

Case study: SpeedMask – application time reduced from 4 hours to 14 minutes

The masking process at MTU Aero Engines, a leading German manufacturer of military and civil aircraft engines, used to involve tapes, silicone rings, masks and metal covers all manually fitted and applied by operators. So when production planner Thomas Kaltenecker discovered and implemented Dymax SpeedMask, a UV-curing temporary masking liquid, alongside an automated dispensing and […]

Read More

Case study: improving overmoulding adhesion with plasma treatment

Founded in 2020, Wavecon specialises in cable solutions for subsea assemblies, offering a range of options from the supply of replacement cable harnesses and wired assemblies, through to fully designed and manufactured bespoke assemblies for specific applications. From the outset, the company decided to build an end-to-end manufacturing process, using high quality equipment, machinery and […]

Read More

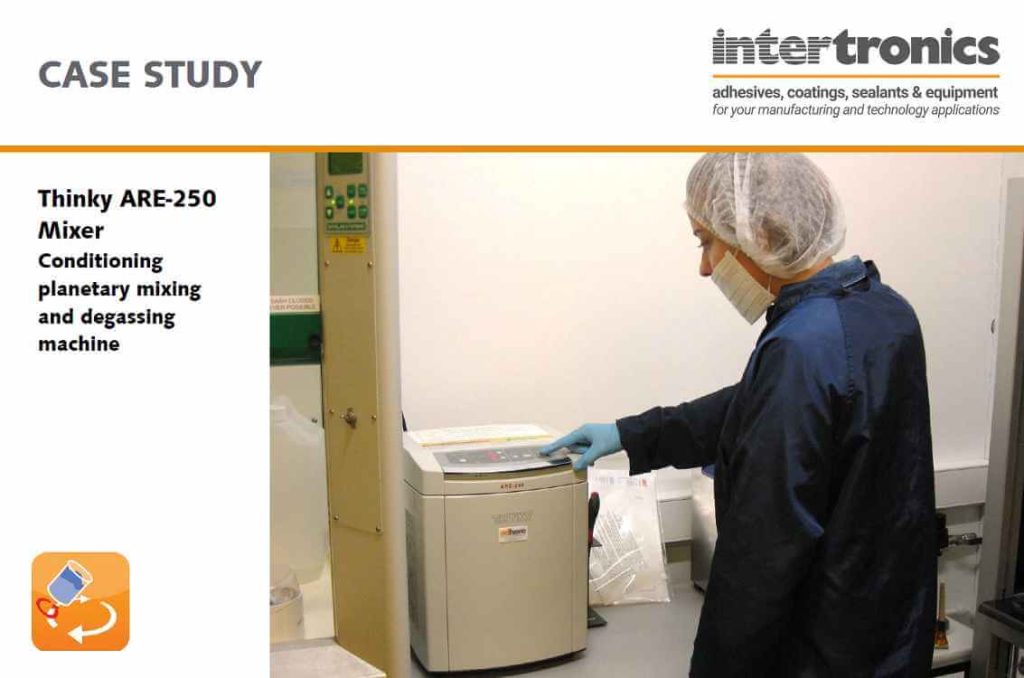

Case study: improving mixing accuracy and repeatability for 3D printed bioelectronics research

To improve the way recovery from injury and the progression of neurological/musculoskeletal conditions are monitored, the Department of Automatic Control and Systems Engineering (ACSE) team at the University of Sheffield is developing a diagnostic glove that includes several flexible bioelectronic sensors. The sensors are formed from elastomers mixed with various conductive nano or micro particle […]

Read More

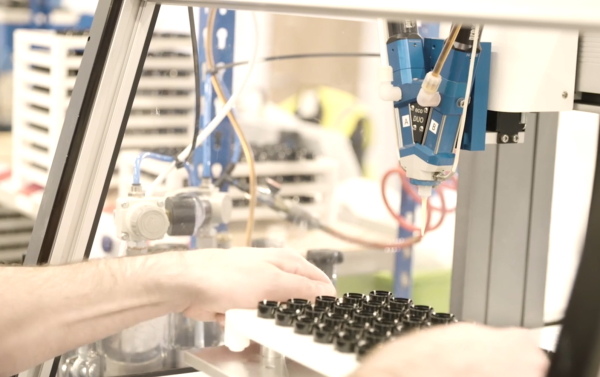

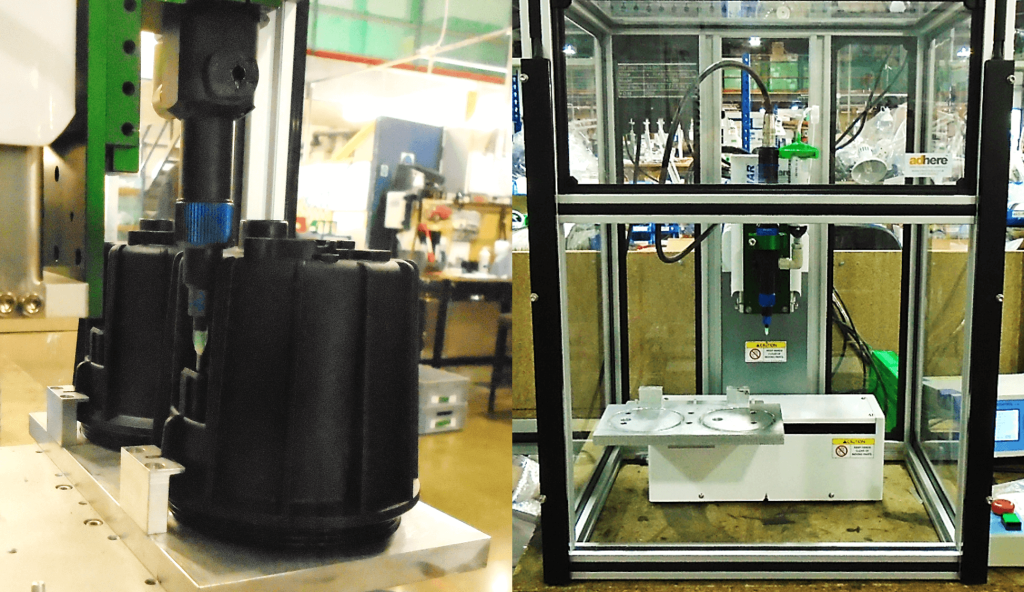

Case study: jet dispensing doubles productivity of water testing kits

To improve the accuracy, repeatability, and manufacturing speed of their key product line Kemio™, a water testing system utilising patented single-use sensor technology, Palintest came to us. Using electrochemical sensors, the product tests the concentration of chlorine, chlorine dioxide, chlorite or peracetic acid in samples, giving a clear pass or fail mark in 60 seconds. Initially […]

Read More

Stories from our customers – a case history collection

“The ability to mask complex shapes in one application and cure quickly on demand has reduced work in progress, improved quality and increased throughput.” “We have managed to increase production four-fold and enjoyed faster manufacturing time, reduced labour costs, and a consistently high-quality result with no defects or wasted material.” “It has allowed us to […]

Read More

Case study: epoxy mixed by THINKY headed to the Moon

It’s been 50 years since the USA softly landed a spacecraft on the Moon’s surface. Something Intuitive Machines, based in Texas, is looking to change. When sending expensive, often delicate, machinery and equipment into the depths of space, achieving the most reliable bonds between components is mission critical. For this very reason, Arnab Roy, Production […]

Read More

Case study: a clear potting process for a sustainable fishing device

To aid the rapid development of a new deep-sea fishing device, sustainable fishing start-up SafetyNet Technologies (SNTech) reached out to us. In a close collaboration, SNTech specified two materials, Opti-tec™ 4210 and IRS 3071, and developed a reliable assembly process. The new device, Pisces Deep, has since passed pressure tests at 100 bar and is […]

Read More

Case study: silicone gasket robotically applied lets lighting manufacturer shine

Providing light where there was once darkness, lighting assemblies have been a staple in modern vehicle manufacture for decades. For many manufacturers, the search for brighter, better-performing systems has led them away from traditional bulbs and lamps towards more complex arrays of LED emitters, with lifespans in the 1000’s of hours. Keeping these assemblies protected […]

Read More

Case study: increasing product design opportunities with Born2Bond Ultra HV CA

As consumers increasingly prefer smaller, more portable, wearable electronic devices, assembling the intricate components can prove challenging. This challenge is further compounded when considering skin contact material requirements and the bonding issues these materials can pose. Fortunately for a wearable electronic device manufacturer, our Born2Bond™ Ultra HV was able to address their bonding challenges while increasing their […]

Read More

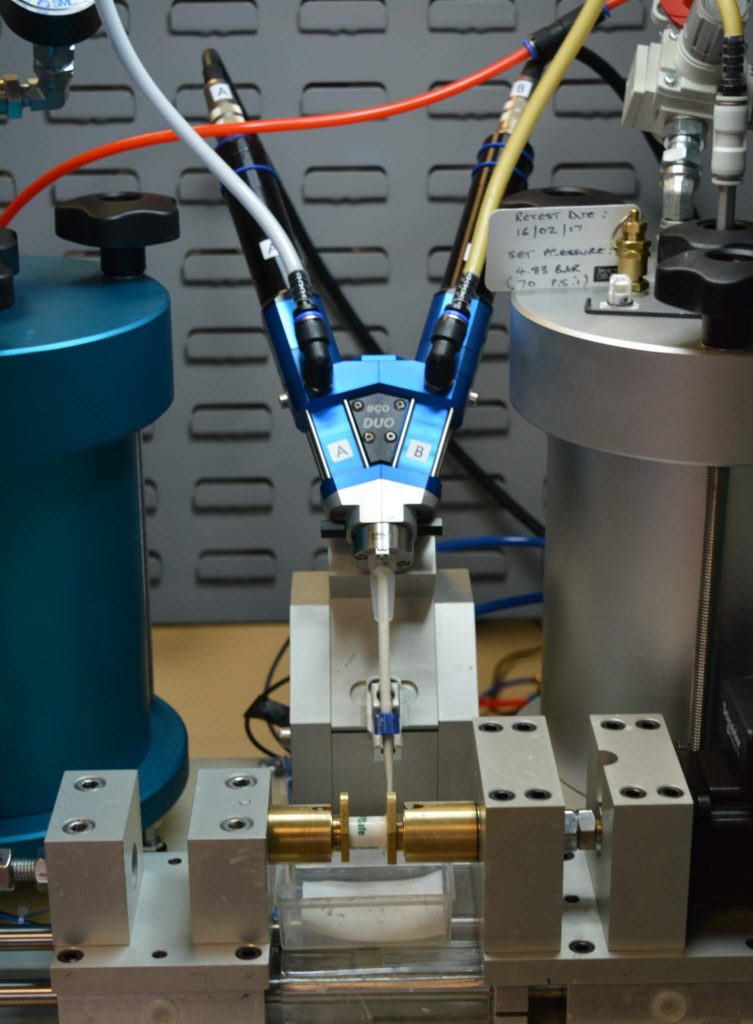

Case study: improving sealing quality while maximising productivity in gas sensor manufacture

When gas sensor manufacturer DD-Scientific wanted to improve the accuracy, repeatability, and productivity of an epoxy sealing process, they asked us. DD-Scientific now benefits from robot-mounted preeflow® eco-DUO precision metering, mixing and dispensing systems, which save the company 23 days of staff time per year, while maintaining the high-quality the company’s products demand. DD-Scientific’s sensors […]

Read More

Case study: putting electronics into an archery arrow with novel CAs

Application In today’s technologically-advanced world, consumers want products that are better, smarter and more intuitive to their needs. For brand owners and manufacturers, this means continuing to push the boundaries on innovative, increasingly-smaller devices that can give consumers new product options unlike anything they’ve seen before. The miniaturisation of devices can pose assembly and bonding challenges, […]

Read More

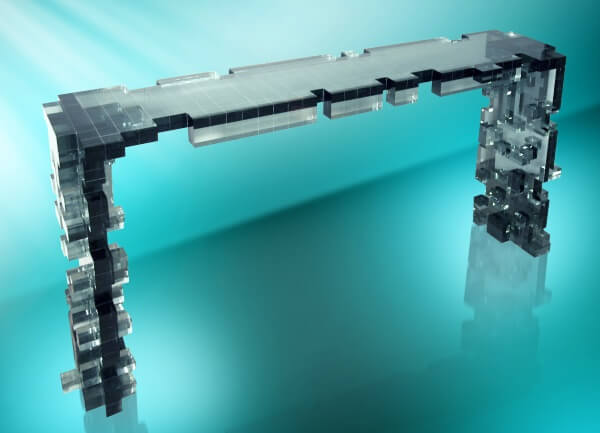

Case study: bonding 3D printed parts

3D printers usually print relatively small stuff – certainly less than 1 meter in any dimension. Our own 3D printer’s largest build dimension is 320mm, and that is fairly common. There are exceptions, of course – these days you can 3D print a two-story house. But for most applications, if you need to make a […]

Read More

Case study: high-quality glass repair in short timelines with Opti-tec 5013 clear epoxy

Anthony Scala, a London-based glass artist and instructor, takes on repair work for glass pieces ranging from sentimental value to more significant worth. In order to complete repairs in a timely manner, Anthony sought an adhesive that offered a fast curing time whilst maintaining good clarity and structural reliability. Opti-tec 5013 Optically Clear, Fast-Curing Epoxy […]

Read More

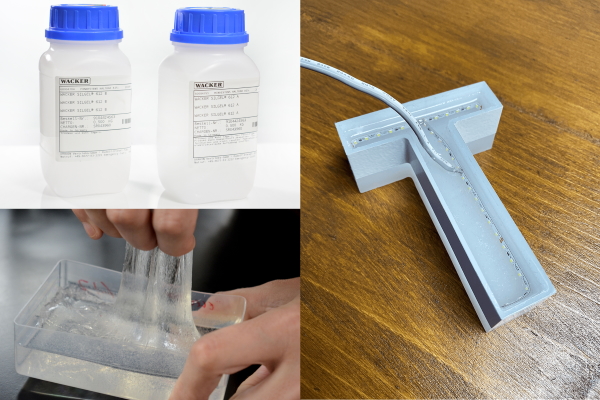

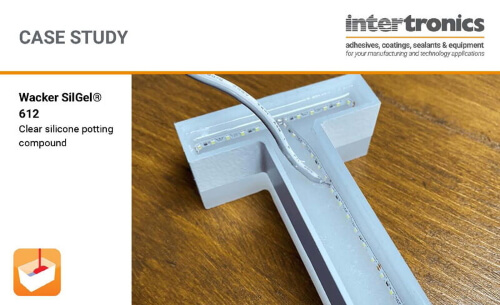

Case study: using silicone gels to protect outdoor LED signage

LED-based lighting technology is being used for manifold and diverse applications, including illuminations outside. For outdoor signage, manufacturers may need to use potting or encapsulation materials to protect LEDs against water, moisture and other environmental factors. Here is a case study of how a manufacturer of outdoor signage used Wacker SilGel 612 to protect its […]

Read More

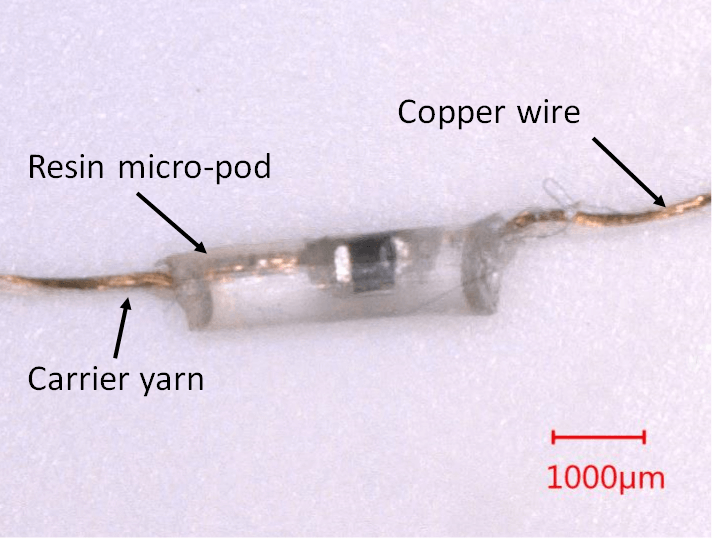

Case study: developing electronic textiles with UV curing

Recent advances in semiconductor and microelectromechanical systems (MEMS) have reduced both their size and cost. The Advanced Textiles Research Group at Nottingham Trent University is incorporating these components into the yarn-making stage to broaden the possibilities for electronic textiles into areas like temperature sensing, medical monitoring, motion sensing, energy harvesting and illumination. By incorporating the […]

Read More

Adhesives in the real world: success stories from our customers

Our customers are doing amazing things, so we’d like to highlight some of their achievements and perhaps provide you with a bit of inspiration for ways to improve your productivity while achieving a great return on investment. Here’s a snapshot of some of our recent case studies: ShotScope has been able to quadruple production of […]

Read More

Case study: LED potting with clear silicone gel

Our latest case study describes the story of a UK manufacturer of outdoor signage and lighting products, who was seeking to encapsulate their LED strips to protect them from environmental damage, whilst maintaining a desirable aesthetic in the finished product. Wacker SilGel 612 Transparent Silicone Potting Gel fit the bill. Read more about it and […]

Read More

Case study: improving masking for electroless nickel plating in aerospace and defense applications

An international company who specialise in manufacturing and repairing landing gear and actuation systems for the aerospace market were looking for efficiencies in their electroless nickel plating process – their target was to automate the masking process and increase throughput. The adoption of Dymax SpeedMask brought process times down from as much as three days […]

Read More

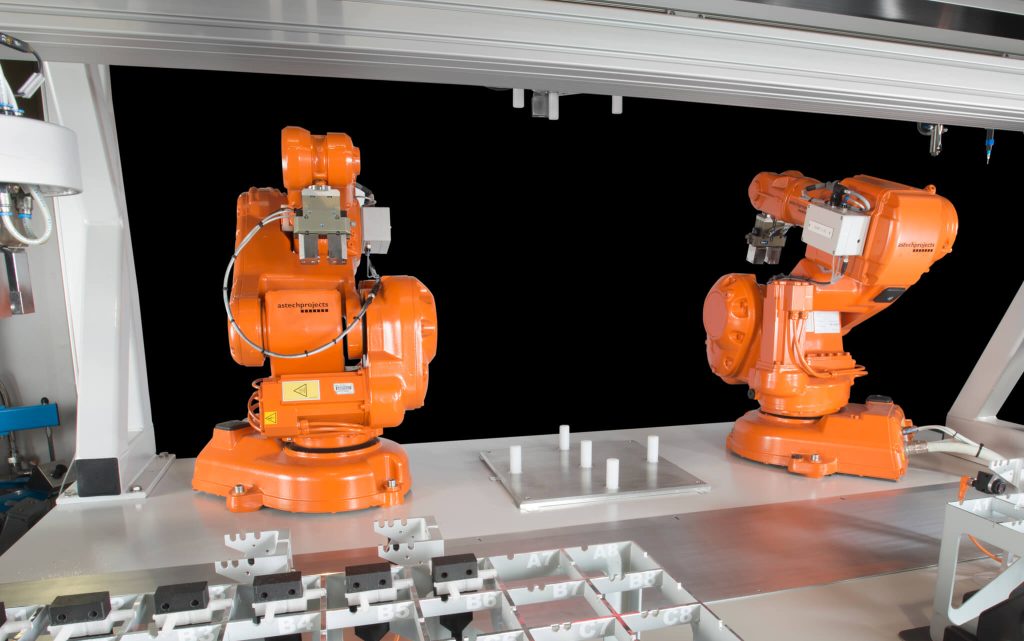

Case study: automation expertise for aerospace temporary masking

The Challenge “A leading UK aerospace company commissioned Astech Projects to build a bespoke Automated Masking System to mask complex areas of aircraft components to avoid precious metal coverage during the manufacturing process,” explained Craig Hamilton, Business Development Manager at Astech Projects. “The system was required to have the capability to mask 14 component variants, […]

Read More

Case study: improving the UV adhesive dispense and cure process

Reducing material waste during the UV curing adhesive dispense and cure process is a common challenge faced by manufacturers. For innovative pump manufacturer Franklin Electric, our partners at preeflow were able to provide a fully integrated adhesive dispensing system to do just this. The preeflow eco-PEN450 not only reduced the manufacturer’s waste and minimised material consumption but […]

Read More

Case study: preeflow precision dispensing improves automotive gasket quality

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow® customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) automotive gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point […]

Read More

Case study: automated sealant dispensing proves a winner for innovative golfing product

Shot Scope Technologies, based in Edinburgh, designs and manufactures innovative wearable technology which helps both professional and amateur golfers to improve their game. A keen golfer with a background in electronics design, CEO David Hunter set up the company in 2014 to develop the golf wearable, which collects and analyses over 100 key statistics from […]

Read More

Case study: mixing and degassing PDMS for microfluidic manufacture

This paper describes the development of a microfluidic platform for the formation and maintenance of blood microvessels. A mould is fabricated using photolithography, which is then used to cast the microfluidic from PDMS (poly-dimethylsiloxane). One of the key issues during the microfluidic production is the complete filling of all the microstructures with the uncured PDMS. […]

Read More

Case study: UV curing gasket aids serviceable Li-Ion battery packaging in automotive industry

GenZe dedicate themselves purely to getting customers where they need to be with their two wheeled electric vehicles. A leading pioneer in the field, GenZe has developed leading edge engineering, R&D, and design innovations in areas including Li-Ion battery production. Packaging state-of-the-art electronics with energy-dense Li-Ion battery cells presents some unique challenges and opportunities The Problem […]

Read More

Case study: adhesive alternative to welding for bonding polycarbonate

The Problem A world leader in electrical explosion protection and sensor technology, was looking for an alternative to laser welding for an application that requires sealing two polycarbonate parts in their photoelectric sensors. The customer was bonding polycarbonate clear covers to a polycarbonate PCB enclosure by laser welding. However, they were unsatisfied with the results, as […]

Read More

Case study: precision epoxy dispensing helps electrical manufacturer improve quality and yield, and reduce waste

Based in Boston, Lincolnshire, Parkinson Harness Technology is a manufacturer of bespoke electrical products to industries such as construction, agriculture, rail and defence. It produces a variety of products including wiring harnesses, control panels, battery/power leads, PCBs and control systems mainly for use in specialist vehicle manufacture. Parkinson Harness Technology also offers engineering support services […]

Read More

Case study: preeflow volumetric spray dispenser ensures the highest sound quality in beyerdynamic headphones

With more than 90 years of experience in the development of audio electronics, beyerdynamic, based in Heilbronn, Germany, stands for innovative audio products with the highest sound quality and groundbreaking technology. The different divisions provide tailor-made solutions for professional and private users. All products are developed in Germany and are mainly manufactured by hand – […]

Read More

Case study: automated silicone dispensing for illuminators in the detector and security industry

Our customer, GJD designs, produces and sells intruder detection products at its factory and head office in Heywood, Greater Manchester. One of GJD’s main products is its line of white-light and infra-red LED illuminators, marketed under the company’s Clarius® brand. Used principally in security applications, they also find other uses, including broadcast production. High performance […]

Read More

Case study: improving quality and increasing pcb production with UV curing conformal coating

The Problem A leading industrial electronics company was developing a new industrial inverter model that required a high cured thickness of conformal coating to meet electric performance. The product they were using at the time was a solvent-based coating with a low cured thickness. Air pollution and odours from solvent based coatings were a concern for […]

Read More

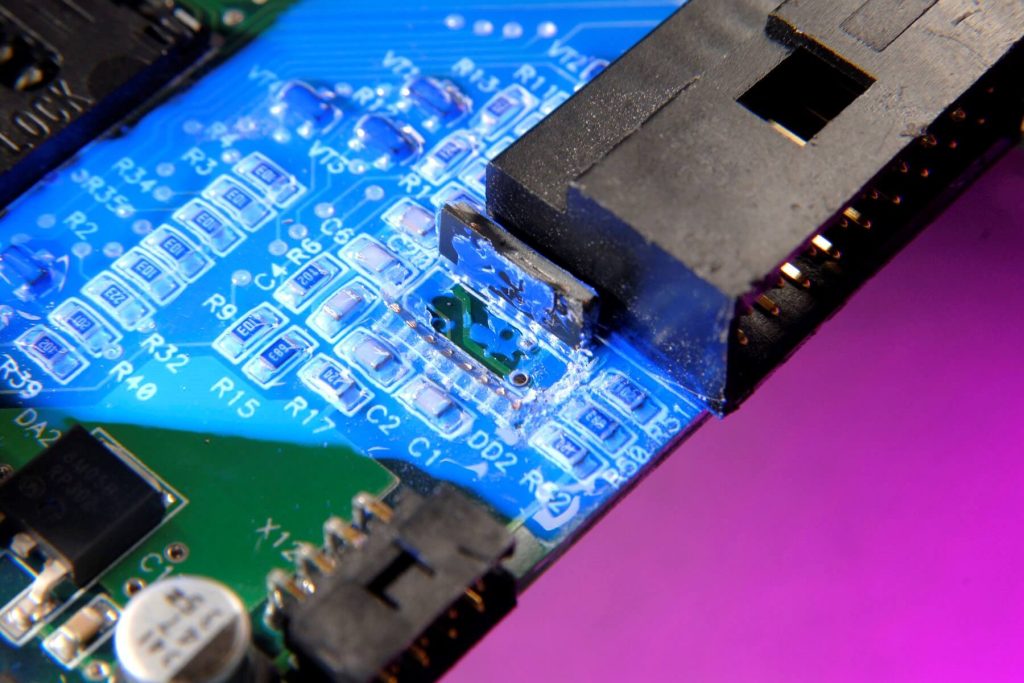

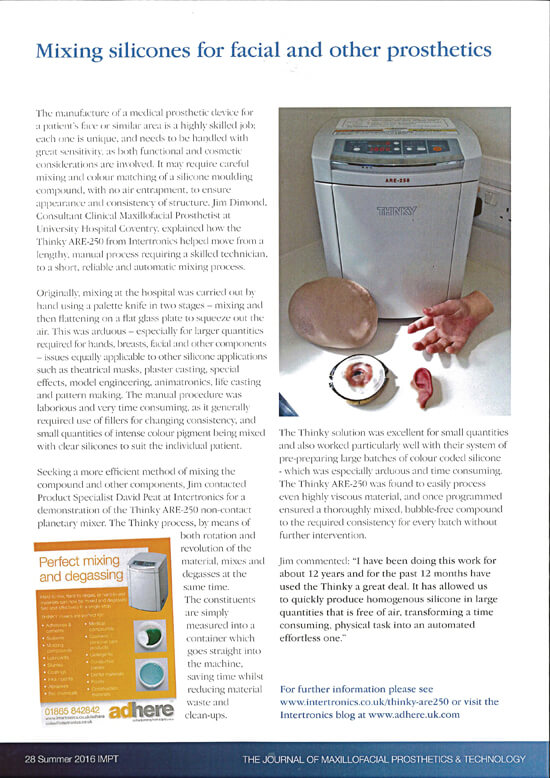

Mixing silicones for facial and other prosthetics – in the press

It’s great to see our Thinky ARE-250 Mixing and Degassing Machine feature in the latest edition of the Journal of the Institute of Maxillofacial Prosthetists and Technologists (IMPT). The piece describes how we worked with Jim Dimond, Consultant Clinical Maxillofacial Prosthetist at University Hospital Coventry to help him save time and improve the quality of their mixing process when mixing […]

Read More

Case study: preeflow volumetric adhesive dispensing helps ensure integrity of life-saving medical device

Our customer BPR Medical, based in Mansfield, Nottingham, is a perfect example of a small British company which combines expertise, creativity and entrepreneurialism to design, develop and manufacture world-beating products for export worldwide and use in the United Kingdom, for which it was rewarded in 2012 with a Queen’s Award for Enterprise: Innovation. As with […]

Read More

Case study: mixing silicones for facial and other prosthetics

The manufacture of a medical prosthetic device for a patient’s face or similar area is a highly skilled job; each one is unique, and needs to be handled with great sensitivity, as both functional and cosmetic considerations are involved. It may require careful mixing and colour matching of a silicone moulding compound, with no air […]

Read More

Success with UV adhesive to make emergency services equipment more rugged

The Problem A leading manufacturer of premium portable lighting was looking to make its safety torches more rugged – they are used by fire fighters, police officers and military troops in the field. Their engineers needed the torches to withstand rough handling and extreme conditions in the field, and to work in a wide range […]

Read More

Advantages of Using Light-Curable Masking for Surface Protection

Dymax SpeedMask® temporary masking resins offer reliable surface protection of components, often more than traditional masking materials such as tapes, lacquers, and waxes. Learn about the advantages of our light-curable maskants in this informative infographic and see a real life example of how switching from thermal tape to a SpeedMask® maskant saved one company 40,000 […]

Read More

Medical device adhesive case study published in BP&R

Thank you to British Plastics and Rubber magazine, who feature one of our recent application stories regarding Brandon Medical in the latest issue. The company used one of our LED UV curing plastic bonding adhesives to save production time. Click on the image to open a copy of the article.

Read More

Harley Davidson selects adhesives over mechanical fasteners

Odyssey Motorcycles used a carbon fibre epoxy composite for parts of on a Harley Davidson Super Sport Roadster (SSR). The French manufacturer used the material to make up the bodywork, petrol and oil tanks of the custom made motorbike, but then faced challenges around how to join it with the rest of the structure. It […]

Read More

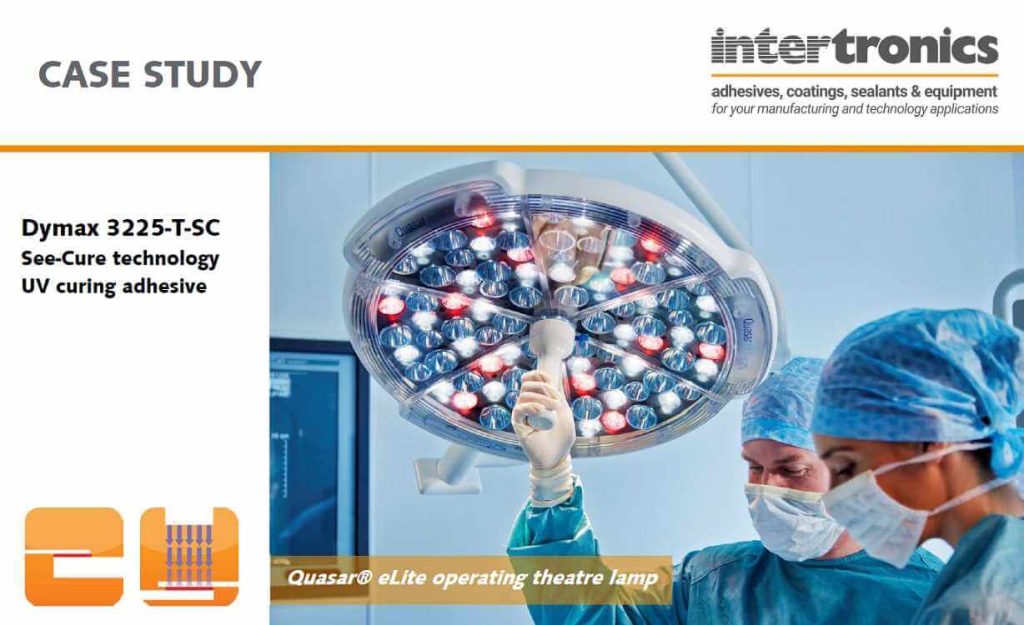

UV adhesive cures time problem for Brandon Medical

Extended curing times for adhesives can often create a bottleneck in the production process which can interrupt work flow. This was exactly the problem experienced by Brandon Medical Ltd. Technical Director Nigel Davill explained: “We had a problem bonding three polycarbonate lenses together to make the large front lens of our Quasar® eLite operating theatre […]

Read More

Material mixing and dispensing prove key for LED production quality

British LED manufacturer Plessey Semiconductors have successfully made the transition from the manufacturing development phase (where manual methods of material preparation and application often suffice) to full production by employing some of our automated mixing and dispensing technologies. Carl Withers, Plessey’s Assembly Development Team Leader, explained: We develop leading edge LED technologies, based on Plessey’s […]

Read More

Thinky Mixer improves bonding processes in optical instrument manufacture

The engineers at optical instrument makers Gooch & Housego use a high specification UV cure adhesive in a military application. It is premixed with microspheres to ensure bondline thickness. However, there were problems in getting a homogeneous dispersion of microspheres in the mix – which could lead to poor fitment of the optical element and […]

Read More

Acrylic bonding – when it absolutely must look right

The high end acrylic fabrication company Dauphin Restoration Ltd, founded in 1986, designs and makes cast acrylic mounts, cases and cabinets for an increasing number of state and private collectors alike. With an invitation to receive the Royal Warrant as Mount Makers to Her Majesty The Queen, Dauphin has established itself as the world’s largest […]

Read More

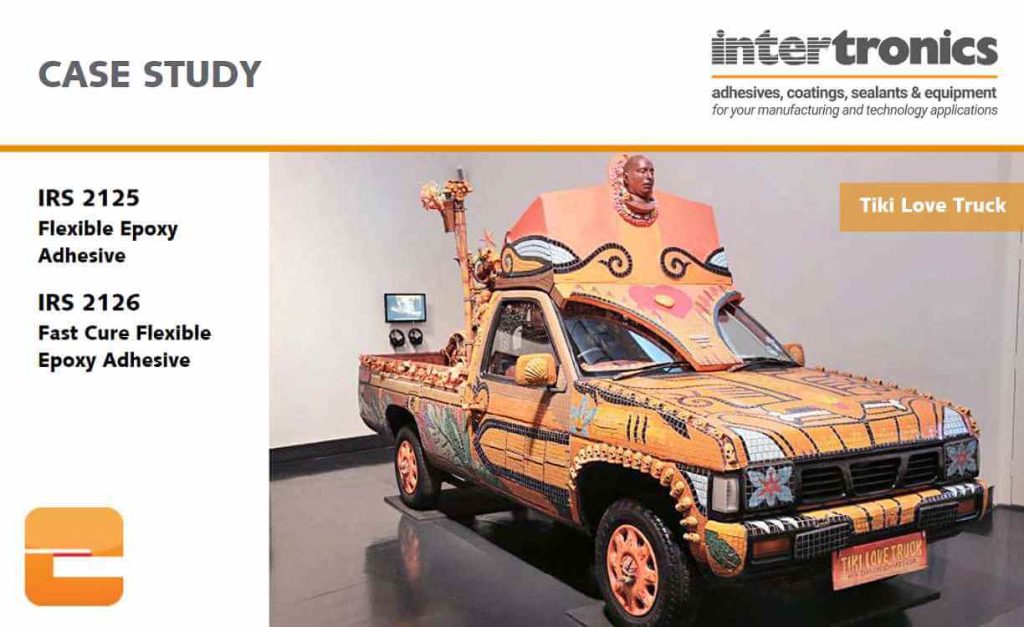

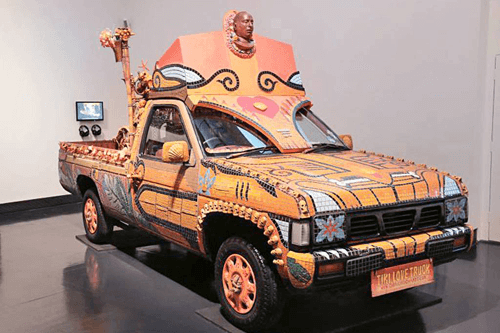

Flexible epoxy adhesive – long term adhesion at the V&A museum

We’re proud to have contributed to the Tiki Love Truck, a prominent exhibit in a major new exhibition at the Victoria & Albert Museum, and one of the best-known creations of British artist Carrie Reichardt – whose work we wrote about recently. Disobedient Objects opened on 26th July at the V&A, Cromwell Road, London SW7 […]

Read More

The art of epoxies – ceramic tile bonding

The fields of art and industry are increasingly converging, a fact that we can ably demonstrate from a long-standing relationship with one of the UK’s leading ceramic artists, to whom we supply epoxy adhesives from our adhere IRS range. Carrie Reichardt describes herself as a “renegade potter, craftivist and anarchist”. Working from a mosaic-covered studio in Chiswick […]

Read More

Araldite adhesives bond racing car wing

Araldite® adhesives have been selected by Norma Auto Concept Engineering to bond the components of a rear wing for a prototype sports car. Founded in 1984 by Norbert Santos and Marc Doucet, whose names make up the brand name ‘Norma’ Auto Concept Engineering, the French-based business manufactures prototype vehicles for a range of racing, endurance […]

Read More

Case studies about electronics potting get FAST coverage

The July 2013 issue of FAST magazine hit my desk this morning – another bumper issue chock full of information about fastening & assembly solutions and technology. It is great to see editor Paul Gay devote a full page to some of our successful recent case studies – Potting compound goes under the sledge hammer […]

Read More

Potting compound goes under the sledge hammer at Tough Tracker

Tough Tracker was established to counter a problem in the scrap metal market – of not knowing where scrap bins (skips, etc.) are located if they get lost or stolen. Electronic tracking devices need to be both robust and with good battery life. The Tough Tracker solution was developed with a high tech composite casing […]

Read More

We pot the green for Variohm with custom thermal potting compound

In setting up a new production project for in-house potting of temperature probes the engineers at Variohm considered a number of well-known industry standard thermal potting compounds – and they called us in. Ben Moffat, project engineer at Variohm, was looking for a potting compound that would give them the best thermal conductivity combined with an […]

Read More

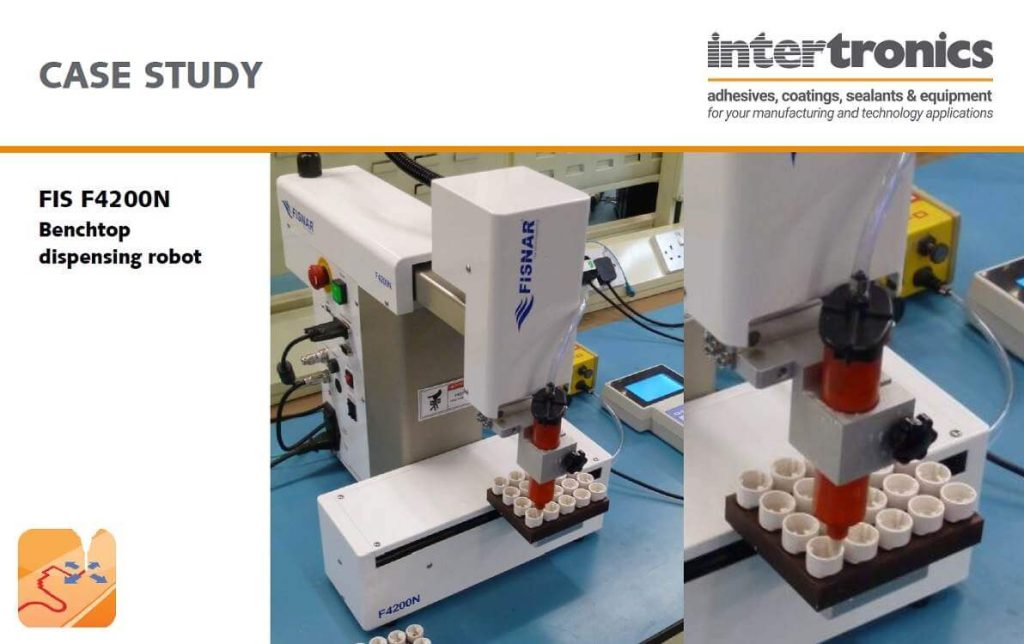

CEM increases competitiveness with dispensing robot

Contract electronics manufacturer CT Production recently contacted us when they needed to expand their dispensing robot capability for a low energy lighting product. Explained CT Production MD Alan Trevarton: It is company strategy to compete with offshore manufacturing by lowering costs using robotics – compared with manual operatives the benefits are greater flexibility, continuous working, reduced […]

Read More

Fast curing metal bonding solution for customer Ford Components

A quick and simple adhesive solution was required for one of Ford Components Manufacturing Ltd’s laminated metal shim pack products. Known as edgepeel®, the pack provides a number of shims, to specific customer requirements, that can be quickly and easily selected at the point of assembly, therefore speeding up production. These thin steel shims are […]

Read More

Potting compound protects trace heating system thermostats

The winters, they tell us, are getting colder and trace heating systems for vulnerable water pipes are finding greater demand. As part of their development process STOPFREEZE were looking for a superior way of protecting their in-line thermostat from water ingress and physical damage in its outdoor situation. Their solution came in the shape of […]

Read More

Araldite 2015 specified in motor cruiser construction

Araldite 2015 has been exclusively specified in the construction of the Neptys First Life 27, a semi rigid power boat made from a vinyl ester infusion. Because of its length, 8.5m, and speed, 50 knots plus, the Neptys First Life 27 is subject to impact and vibrations and needs an adhesive combination that could withstand […]

Read More

We stick urban art together

Modern art is such an integral part of life, the interweb and everything, that some exciting projects are taking place – perhaps where they always have – at the borders between the street and the gallery. So it is even more interesting to find this kind of project dependant upon an advanced flexible epoxy adhesive […]

Read More

Sea lion studies with Araldite 2012

Very little is known about the diving behaviour of young sea lions who flourish on the Galapagos islands – which is where Araldite® 2012 comes in. Araldite 2012 was found to be the best adhesive to attach recorders and study repeated dives of sea lions down to 350–500 metres. The adhesive has to withstand the […]

Read More

Alternative art adhesive

Baroness Carrie von Reichardt and her partner were asked by the Mutoid Waste Co to be involved in a show called Mutate Britain, where a number of well-known artists where each given pieces of a WW2 war plane and asked to let their creative juices flow. Explained the Baroness: We were actually given two panels […]

Read More

Dyson Clean and Dry with Araldite 2000+ Adhesives

Dyson relies on Araldite® 2000 PLUS adhesives in its leading-edge vacuum cleaners and hand dryers. In Dyson vacuums, which use Cyclone Technology™ to separate dirt and dust from the air using high centrifugal forces, Araldite adhesives bond together core parts of the cyclone system that gives Dyson vacuums their superior cleaning power. Having tested Araldite […]

Read More

Mixing glass powders into resin

James Kent (Ceramic Materials) Ltd had relied for many years on a manual mixing system for their research and quality control of specialist glass powders, but embarked on a search for a process solution that would be more effective, more consistent, quicker and simpler. The glass powders produced by James Kent Ltd are tailored to […]

Read More

They nail horse shoes, don’t they?

Yes indeed, we found that they do nail horses’ shoes – but in the process of custom fitting each shoe a farrier will generate a lot of impact energy on his anvil – not only does this cause the ear damaging “ringing” sound but also generates a potentially damaging reflective shock wave up the hammer […]

Read More

Making a fashion statement

You probably already know that products from Araldite can be found in almost all areas of life. But it may come as a bit of a surprise to you that products made of our advanced materials can also enhance your personal glamor. Working closely with Swarovski, the Austria-based manufacturer of crystal jewelry, Huntsman has again […]

Read More

Clock this!

World renowned clocks have been made in Derby since the mid-1700’s, when clockmaker John Whithurst entertained his friends Benjamin Franklin and Erasmus Darwin (grandfather of Charles Darwin) at his house in Queen Street. So, when the Finesse Collection of hotels were planning the reception area of their new boutique hotel in the town it was […]

Read More

We get stuck into the Love Truck

The problem involved a painted steel substrate, hand placed glass/ceramic tiles, substrate flexing and widely varying vibration over extended periods in outdoor conditions – in short a Tiki Love Truck! An unusual project even for us, but nonetheless as it proved, well within the capabilities of the adhere IRS 2125 Flexible Epoxy Adhesive. The project […]

Read More

Pushing the boat out

An aluminium speedboat, built by the Dutch company Silvestris Haute Motive Concepts, is making use of structural bonding technology from Huntsman Advanced Materials. Martin de Bruijn, a designer at Silvestris, reveals that the design practices and lightweight materials used mean that the 23-foot boat weighs just 1500kg. The light weight is based on an aluminium […]

Read More

Rocking your world – high temperature epoxy fixes speaker coils

Real World engineering is rarely rocket science, but often it is very much about pushing the boundaries of performance and balancing conflicting parameters. This was exactly the kind of situation which we met when a customer asked our advice on an adhesive application. This unusually challenging application was in the production of very high power […]

Read More