Cyanoacrylate adhesives (CAs) have been around since the 1950s, and from the 1970s they have become a common household product. Today, manufacturers are increasingly using CAs and rely on them to bond plastics, metal, ceramic, rubber, wood and other substrates in many types of assemblies. They are unique in that they provide fast curing and high-strength single-part bonding to various substrates without the need for a separate heat or energy source.

There are a number of cyanoacrylate monomers which are used to formulate cyanoacrylate adhesives:

- Methyl (MCA) – primarily for metal-to-metal applications

- Ethyl (ECA) – for plastic, metal, wood, ceramics and glass substrates (the most commonly used in both industry and household)

- Methoxyethyl (MECA) – for low odour, low bloom formulations

There are others: octyl monomers are used to make medical products for bonding skin, for example.

Despite their popularity, up until now cyanoacrylate adhesives have drawbacks based around brittleness, limited temperature and moisture resistance, and other physical disadvantages. There are bad perceptions around odour, and poor aesthetic outcomes due to blooming. These have limited their appeal and application. MECA-based formulations, which mitigate some of the issues around blooming and smell, compare poorly with ECA-based products in terms of speed and strength.

The Born2Bond range represents a big step forward in the technology of cyanoacrylate adhesive chemistry. Due to a proprietary new “crackless” manufacturing process, this new portfolio of ground-breaking engineering adhesives – focused on ‘by-the-dot’ bonding applications – breaks new ground.

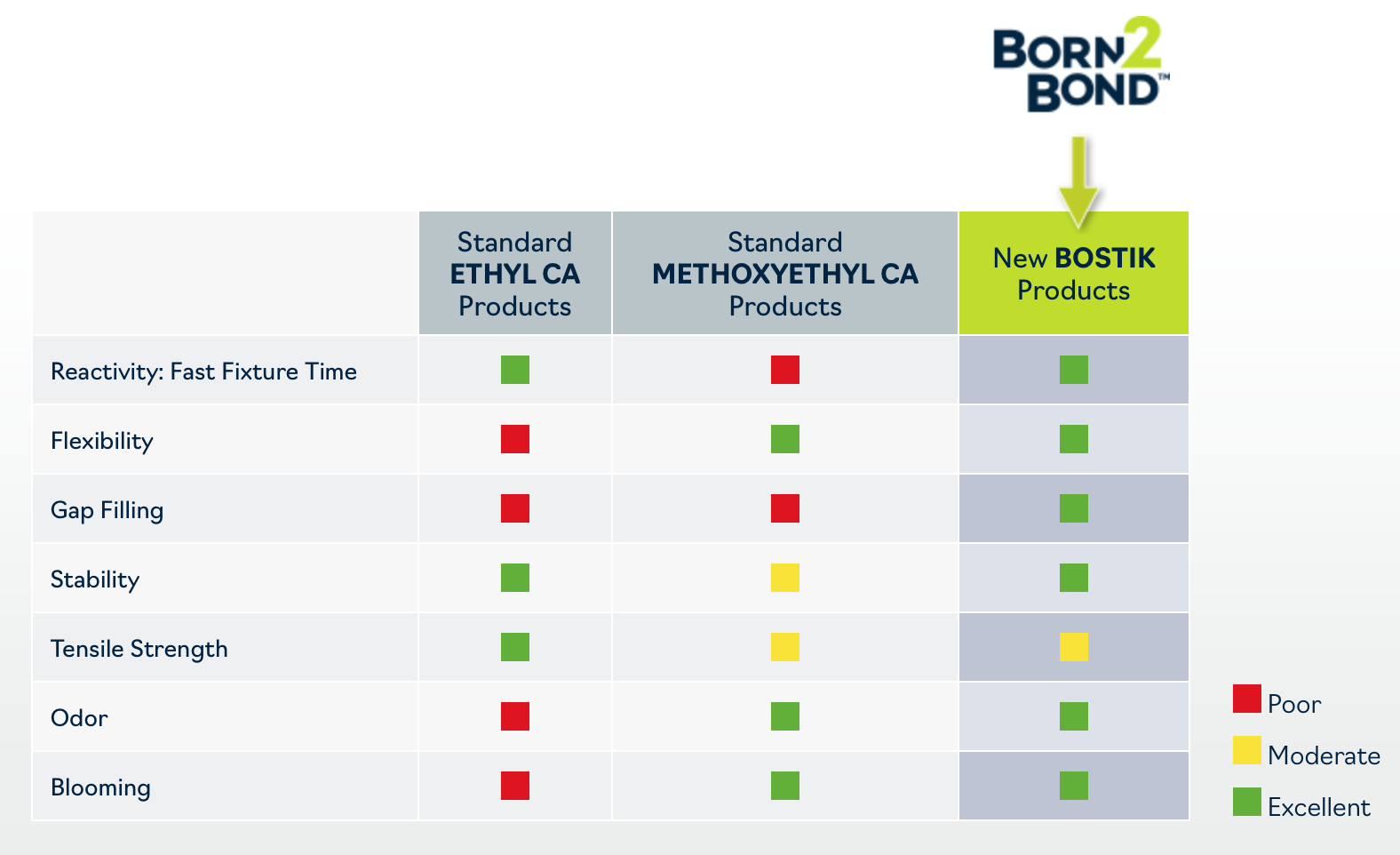

The chart illustrates that Born2Bond Cyanoacrylate Adhesives overcome many of the performance and application limitations of existing products. They also facilitate faster, smarter production processes while prioritising user safety and sustainability. The days of compromise in “instant” adhesive choice may be over.

Some of the implications for your production:

- High adhesive strength

- Higher operating temperature – up to 120°C

- True flexibility

- The only two-part cyanoacrylate adhesive on the market with >200% elongation

- Gap filling

- Low odour, low blooming without compromising speed

- Fastest curing MECA-based products in the market

- High impact resistance, high toughness

- ISO 10993 tested and suitable for consideration in the assembly of medical devices

- Long pre-assembly open times

- May be machined, drilled, sanded and painted

- Safer products, fewer or no label hazard symbols

- Non-irritating

Take a look at the five new products in the Born2Bond range to see what makes them special. We are keen to help you use them to achieve your production goals.

Categories: adhesives, bonding acrylic, cyanoacrylate adhesives, medical, plastics, rework and repair, what's new