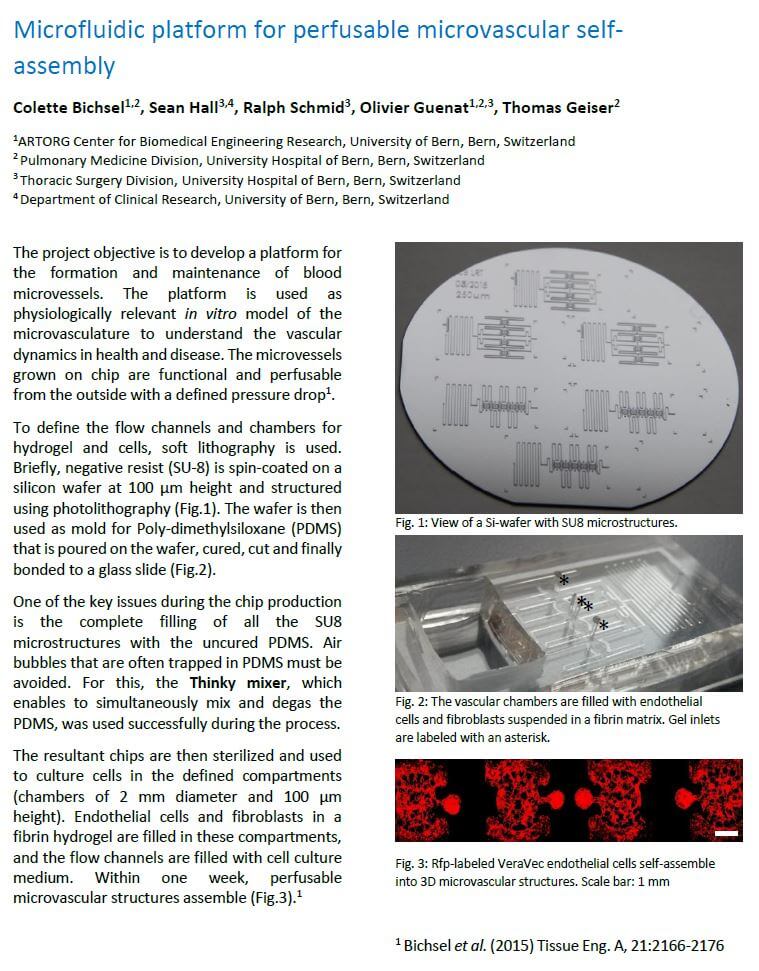

This paper describes the development of a microfluidic platform for the formation and maintenance of blood microvessels. A mould is fabricated using photolithography, which is then used to cast the microfluidic from PDMS (poly-dimethylsiloxane). One of the key issues during the microfluidic production is the complete filling of all the microstructures with the uncured PDMS. Air bubbles that are often trapped in PDMS must be avoided. A Thinky mixer was used successfully during the process, enabling them to simultaneously mix and degas the PDMS.

Thinky mixers with their twin mixing and degassing modes, give fast, efficient and homogeneous mixing of many high technology materials. For ultra-critical applications, where even micro-bubbles cannot be tolerated, models with integral vacuum like the Thinky ARV-310 are recommended. Results show that no bubbles can be observed in a cured resin, even at 100x magnification.

Categories: case study, mixing