GenZe dedicate themselves purely to getting customers where they need to be with their two wheeled electric vehicles. A leading pioneer in the field, GenZe has developed leading edge engineering, R&D, and design innovations in areas including Li-Ion battery production.

Packaging state-of-the-art electronics with energy-dense Li-Ion battery cells presents some unique challenges and opportunities

The Problem

Packaging state-of-the-art electronics with energy-dense Li-Ion battery cells presents some unique challenges and opportunities. After an extensive design process GenZe engineers created a safe, aesthetically pleasing, yet extremely complex removable battery system without compromising other design aspects such as weight, performance, and safety. The manufacturing engineering team then had to develop a process suitable for mass production that would allow the team to assemble the system, disassemble the system for servicing and then reseal the system reliably and repeatedly. Extensive trialling of different options ranging from solid die cut gaskets to individual O-rings and liquid materials were run but none of the trials proved to be a solution to provide the necessary sealing performance while being easy to apply.

This dispensable gasketing material demonstrated previously unseen flexibility to the product engineers

The Solution

After visiting the GenZe production floor to assess the process, a team from our partners Dymax suggested a solution – Dymax GA-201 UV Curing Form-In-Place (FIP) Gasket – that would satisfy the needs of the application, not only in terms of sealing protection, but also in terms of manufacturability. This dispensable gasketing material demonstrated previously unseen flexibility to the product engineers. By using this material, the product’s styling and packaging would no longer be limited by its sealing requirements.

In a very short time, battery assemblies that power the GenZe 2.0 scooter were in production

The Results

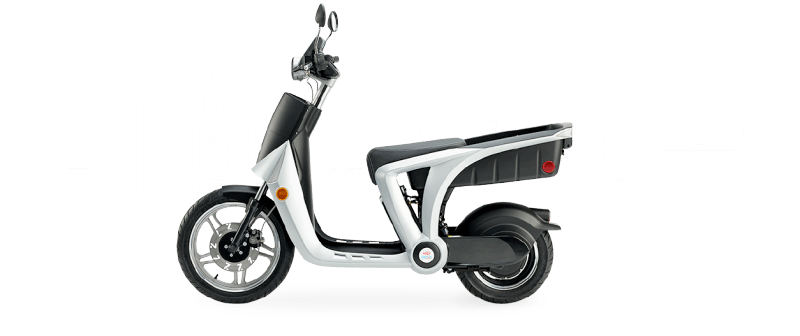

After running months of performance and validation testing, Dymax GA-201 UV curing gasket proved to be the solution GenZe was searching for. The Dymax team also assisted GenZe process engineers with the selection of the proper dispensing and UV curing systems, allowing the process to be implemented as soon as possible. A complex manufacturing cell, which includes a 6-axis robot complete with precision dispensing equipment and a Dymax BlueWave® 200 curing unit, was installed. In a very short time, battery assemblies that power the GenZe 2.0 scooter were in production and passing the rigorous in-process tests with flying colours.

Categories: automotive, case study, gaskets, uv curing