The Problem

A leading industrial electronics company was developing a new industrial inverter model that required a high cured thickness of conformal coating to meet electric performance. The product they were using at the time was a solvent-based coating with a low cured thickness. Air pollution and odours from solvent based coatings were a concern for environmental and health & safety reasons. The business was looking for an environmentally friendly and solvent free coating to use in order to enhance quality and increase production of their printed circuit boards.

The Solution

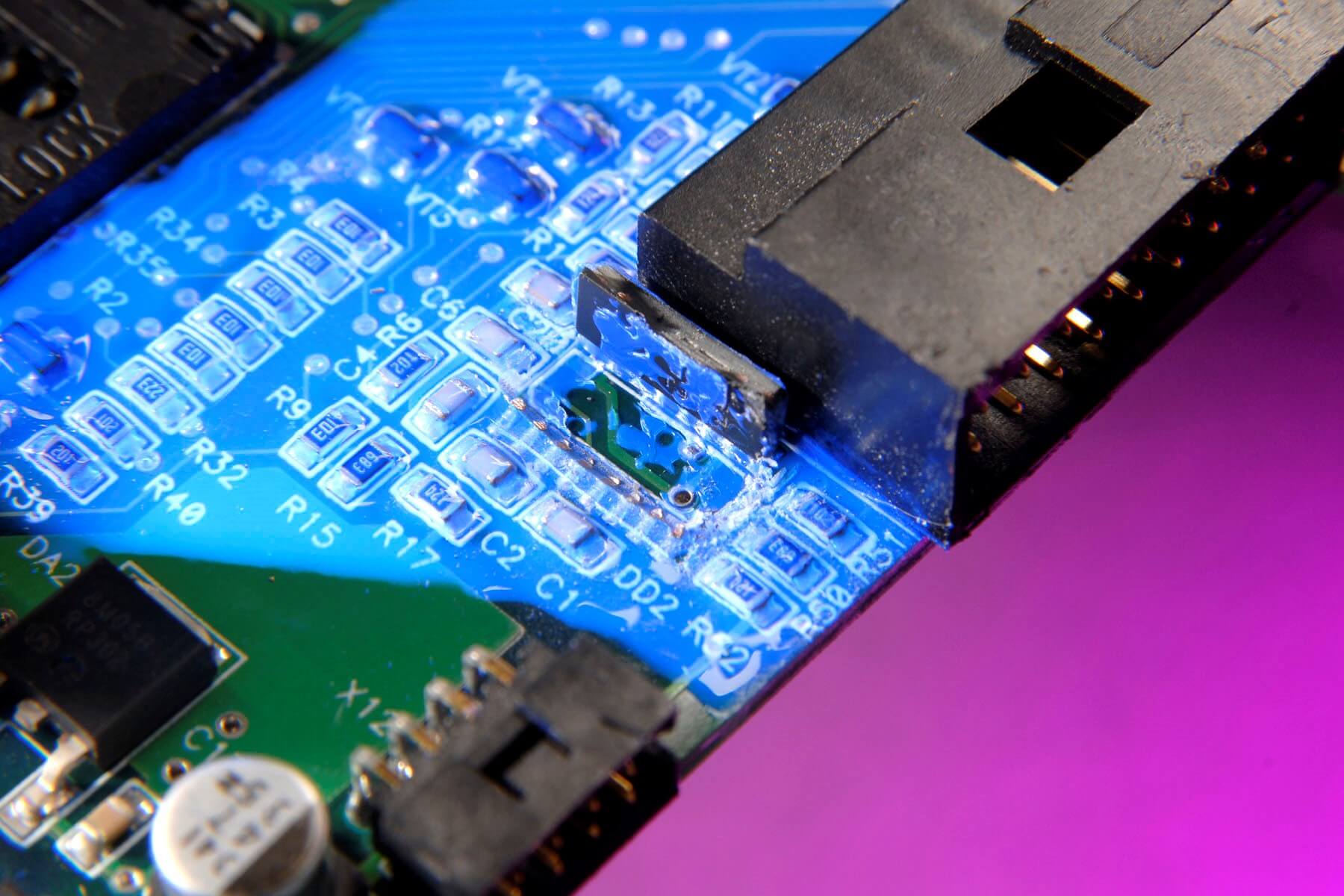

Committed to nurturing collaborative partnerships with customers, our partners in the Dymax Application Engineering (AE) team worked closely with the customer to come up with an innovative solution to protect the pcb’s from harsh environments. The customer needed an environment-friendly conformal coating that does not crack, delaminate, or show signs of corrosion, while maintaining mechanical and electrical properties after testing. After tests with the customer’s parts, the team recommended Dymax 9482 Dual-Cure Light/Moisture-Cure Conformal Coating. This material’s secondary cure mechanism ensures the curing of any coating which goes underneath components into shadowed areas which wouldn’t cure with light. This conformal coating achieved a UL 94-V0 flammability rating up to 10 mm thick, which makes it suitable for environmental protection of circuitry, wire harnesses, electronic components and other surfaces needing a protective coating. It passes thermal shock requirements from -55°C and up to 135°C at 0.25mm, while protecting against moisture, condensation, dust, dirt, salts, chemicals, abrasion, thermal shock, mechanical shock and other factors that can all affect circuit performance.

Dymax 9482 proved suitable for the customer’s application as it is engineered for coating thicknesses up to 250 µm and becomes tack free immediately after UV curing, helping to avoid handling defects and reduce processing time and costs. It contains no non-reactive solvents and fluoresces vivid blue when exposed to UV blacklight (365 nm) for easy post-cure inspection.

The Results

The customer was very satisfied with how the Dymax material improved their process, allowing them to increase output by 30%.

Categories: case study, conformal coating, electronics, uv curing