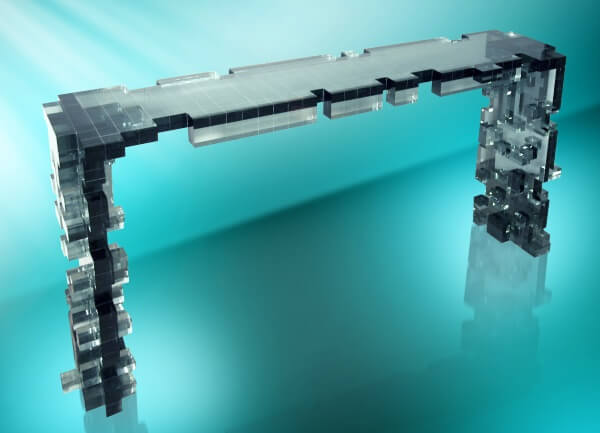

The high end acrylic fabrication company Dauphin Restoration Ltd, founded in 1986, designs and makes cast acrylic mounts, cases and cabinets for an increasing number of state and private collectors alike. With an invitation to receive the Royal Warrant as Mount Makers to Her Majesty The Queen, Dauphin has established itself as the world’s largest maker of exquisite cast acrylic (Perspex®) mounts, stands and holders for collectable items. So when they received an important private commission for a museum quality decorative display table in 40mm smoked acrylic to go in a high end modern London house, they reviewed the assembly process with our specialist adhesives engineering sales team.

The design called for a large number of small acrylic blocks (approx. 100) to be fixed onto three larger pieces of thick smoked acrylic, forming a contemporary cubist style table. The cubes not only add thickness and style, they contribute strength at the joints where the structure is built up a block at a time. Most especially the whole assembly – joints and all – would be fully visible to the world and absolutely must pass 100% inspection.

Explained Alex Abbott of Dauphin:

It became clear at an early stage that a UV and visible light cure adhesive was the only way to do the job. It would give us the opportunity to apply, assemble and inspect at our leisure so we could ensure full coverage and no bubbles. We were able to then wipe off any excess after adjustment and light cure in seconds so we could move on to assemble the next block almost instantly and with full confidence in the integrity of the work we were building up.

DYMAX Ultra Light-Weld® 3099 UV/visible light curing adhesive was applied manually with a dispensing gun and cured in seconds with an IUV250 UV curing flood lamp.

Abbott continued:

We have six people using adhesives on a daily basis so this new and very high quality project gave us the opportunity to develop expertise in UV technology with the help of Intertronics staff who provided guidance and training. The initial investment cost was quite low and the material proved more reliable than other adhesives where bubbles can develop in the curing process. Not only were we able to produce a very high quality piece more quickly than otherwise – we have now developed our expertise with this process which we will continue to use on a daily basis and expect to make significant savings in time and rework costs as a consequence.

Categories: adhesives, bonding acrylic, case study, plastics, uv curing