If you are manufacturing medical devices, we want to recommend to you a feature article by Nadine Blaesing from our partners DYMAX.

Building Better Bonds Using Light-Cure Adhesives

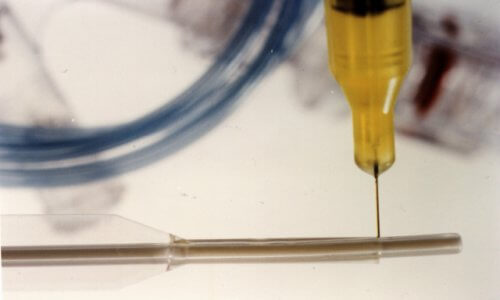

The use of light-cure adhesives can optimise product assembly and reduce material waste, thereby achieving cost savings in the production process without affecting quality

Medical device manufacturers have faced the most challenging economic conditions in decades during the last couple of years, and they have aggressively sought ways to reduce production costs without sacrificing product quality. Optimising assembly process efficiency and minimising material consumption are viable pathways for reducing manufacturing costs. Adhesives are well suited for many assembly operations that involve bonding and joining. In these applications, light-curable materials (LCMs) can help to increase productivity and reduce waste compared with traditional two-part, thermally cured or solvent-based adhesive systems…