The Relyon Plasma PiezoBrush® PZ2 has nozzle attachment options for surface activation across a wide range of applications. Treatment of metals, and smaller and more precise applications are now possible. The use of a variety of special gases enhance the possibilities of PDD (Piezoelectric Direct Discharge) on challenging substrates. Based on the direct, electric discharge at an openly operated piezoelectric transformer, low input voltage is transformed, resulting in high electric field strengths. The PiezoBrush PZ2’s ionised energy output of cold active plasma gives pre-treatment and surface activation, enhancing wetting and adhesion.

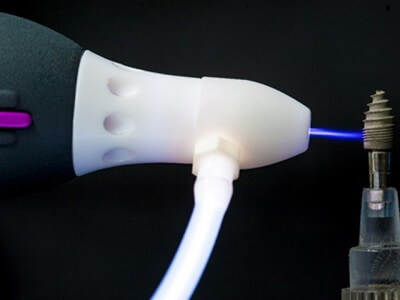

The PiezoBrush PZ2 shown with its three nozzles – Standard, Nearfield and Multigas & Needle

The PiezoBrush PZ2 shown with its three nozzles – Standard, Nearfield and Multigas & Needle

Activation of Metals

When used on conductive surfaces, direct plasma discharges can damage some substrates or even the plasma device itself. The PiezoBrush PZ2 Nearfield Nozzle helps resolve this. Inside the PZ2 Nearfield Nozzle, a glass inlet forms a dielectric barrier and changes the type of discharge, distributing the power from the direct discharge uniformly over the treatment area, therefore eliminating the ability to damage the surface. This allows metals and other conductive substrates to be treated.

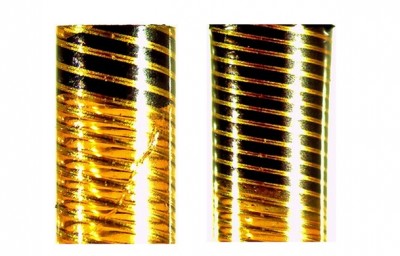

Surface activation using the PZ2 Nearfield Nozzle can allow printing on materials which at normal conditions form poor bonds with inks. The example shown below is a printed anodised aluminium and polyethylene composite material (Alu-Dibond®). The cross-cut test illustrated on the patterns show that, although the ink was barely cured, there is a clearly recognisable adhesion improvement. A short treatment by the PiezoBrush PZ2 on the right gave distinctly better results for the ink bonding.

|

|

| Before surface treatment | After surface treatment |

Activation for Medical Device Technology

The PZ2 Multigas and Needle Nozzle can be used without a special gas (using ambient air) for a very precise surface activation treatment. The narrow output of plasma energy can be used for the treatment of very fine structures including undercuts or small holes.

Alternatively, the PZ2 Multigas and Needle Nozzle can be used with an input of selected inert gases, which allows processes to be implemented which were previously impossible with normal gases such as air or nitrogen.

To treat Teflon (PTFE), a plasma gas with a special composition is used. An example application is these small PTFE inner coated catheters which are successfully treated to allow improved wetting. The picture shows the different degree of wetting of the catheter on the basis of capillary forces. An improvement of over 300% can be achieved.

Note: The magnification of the two pictures is different; the number of diagonals can be used as a reference

Categories: medical, surface preparation