The fixture time for an adhesive (sometimes called the set time) is the shortest time required by the adhesive to develop handling strength such that substrates can be removed from fixtures, unclamped, or handled without stressing the bond – stress which might affect the ultimate bond strength. We can define handling strength as a (relatively) low level of bond strength initially achieved by an adhesive which allows substrates to be handled, moved, or unclamped without causing disruption of the curing process or affecting the bond strength.

The fixture time for an adhesive (sometimes called the set time) is the shortest time required by the adhesive to develop handling strength such that substrates can be removed from fixtures, unclamped, or handled without stressing the bond – stress which might affect the ultimate bond strength. We can define handling strength as a (relatively) low level of bond strength initially achieved by an adhesive which allows substrates to be handled, moved, or unclamped without causing disruption of the curing process or affecting the bond strength.

These are the definitions from ASTM Standard D 1144 Standard Practice for Determining Strength Development of Adhesive Bonds; the standard does not give any objective measure for determining handling strength, and so similar to working life, it may depend on your own particular application.

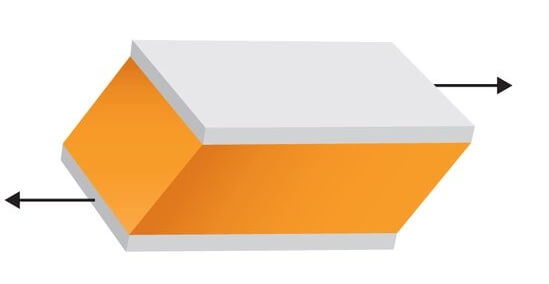

Adhesive shear strength

Adhesive shear strength

Some adhesive manufacturers are more specific in their product data sheets. For example, Dymax usually quote a fixture time defined as “the time to develop a shear strength of 0.1N/mm2 between glass slides. Actual cure time typically is 3 to 5 times fixture time.” As Dymax’ UV curing adhesives have fixture times of seconds or fractions of a second, full cure is still very quick! By their nature, UV light curing adhesives will quickly reach full cure before being removed from any tooling or fixtures. In the case of parts bonded with slower curing adhesives (e.g. two part epoxies) which have full cures of minutes to hours, it may be expedient to remove the parts from fixtures before complete cure.

As part of your adhesive testing and process validation, a practical determination of the handling strength and fixture time for your specific project will be useful.

Categories: adhere academy, adhesives, reference