You can buy two (or more) part adhesives which have been pre-measured into the correct proportions, mixed and degassed, filled into a dispensing syringe or cartridge, and then frozen to stop the cure. The adhesive is shipped from the factory to you in an insulated box also containing ice. Upon delivery, you store the adhesive in a freezer until you need it. In order to use the adhesive, the syringe is taken from the freezer and brought up to room temperature, when it can be applied as normal. This premixed and frozen packaging alleviates potential quality and process issues which can come from metering and mixing in-house, and reduces process steps in manufacturing.

You can buy two (or more) part adhesives which have been pre-measured into the correct proportions, mixed and degassed, filled into a dispensing syringe or cartridge, and then frozen to stop the cure. The adhesive is shipped from the factory to you in an insulated box also containing ice. Upon delivery, you store the adhesive in a freezer until you need it. In order to use the adhesive, the syringe is taken from the freezer and brought up to room temperature, when it can be applied as normal. This premixed and frozen packaging alleviates potential quality and process issues which can come from metering and mixing in-house, and reduces process steps in manufacturing.

Premixed and frozen adhesives supplied in syringes can give some key benefits to busy manufacturers:

- No need to weigh, measure or meter the two or more constituent parts

- No mixing

- As it is premixed, there is less likelihood of epoxy crystallisation

- There is no material separation or sedimentation in storage

- The adhesive is degassed when filled into the syringe, so there are no bubbles or voids

The premixed and frozen approach is more popular with high value adhesives going into critical applications (i.e. electrically conductive adhesives).

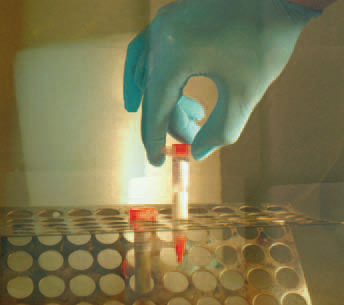

One simple, but nevertheless important, rule must be observed when removing syringes from the freezer: the syringes must only be touched by hand (protected by gloves, of course!) at the flange of the syringe. This is to avoid a local expansion of the syringe wall by uncontrolled heating i.e. by the warmth of your hand – consequently sucking air into the syringe. This may create bubbles inside the syringe and result in voids during dispensing.

A controlled thawing process is simple:

- Wear gloves

- Grip the syringe at the flange

- Take it out of the freezer

- Put it into a rack or close fitting metal cylinder, maintaining vertical alignment with the dispensing end pointing down

- Let it thaw, bringing it up to room temperature (~20-30 minutes)

- It’s now ready to go!

Categories: adhere academy, adhesives, electrically conductive, thermally conductive