In part 1, we talked about shelf life. Let’s turn our attention to pot life and working life, and how they can affect both your specifying decisions and your process.

In part 1, we talked about shelf life. Let’s turn our attention to pot life and working life, and how they can affect both your specifying decisions and your process.

Pot life and working life can be taken to mean the same thing, although in fact there are distinctions between the two terms. They can both refer to the period of time after mixing during which an adhesive or other material remains suitable for use. Note that we are talking about two part systems (or more than two parts). Single part adhesives like our range of UV curing products can be said to have an indefinite pot life, as they remain in their uncured state until they are exposed to the curing light. But our products based on chemistries like epoxy, polyurethane, silicone and methacrylate are typically two part systems; once mixed, the clock starts ticking.

Working life for two part systems like epoxies will be an important selection factor

What is pot life?

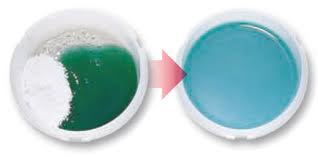

Pot life is a data point liked by the chemists in the lab, as it is defined as the amount of time it takes for an initial mixed viscosity to double, and it is something they can measure. There are variations on this theme – the test is affected by the mass of the material mixed and the temperature, so these factors should either be standardised or detailed (i.e. 100 grams mixed at 25ºC) if you want to make comparisons. Adhesives which require elevated temperatures to cure, or exhibit high thixotropy, may need to be treated differently. Many of these thermoset materials will generate heat (exotherm) during the cure process, and so the temperature will increase during curing, and since this exotherm is related to the mixed mass – the more you mix, the shorter the pot life.

What is working life?

Working life, on the other hand, is the amount of time a mixed material remains low enough in viscosity so that it can still be readily applied to a part or substrate in your particular application, with the appropriate accuracy and tolerance. So working life is application dependent. Size and shape of bondline, geometry, orientation, and even dispensing/dosing methodology will all come into it. As such, there is no standard method of determining working life, except what it turns out to be for your project. Working life is also called open time.

Pot life can act as a guide in figuring out your working life – but some practical experimentation will be useful. Working life is generally shorter than pot life. There are risks in using a material beyond its stated pot life, even if it is still thin enough to apply, because if the cross linking has gone too far before application, then adhesion and other physical characteristics may be compromised.

Not all manufacturers quote pot life or working life in the same way, so be careful of making data sheet comparisons, and use the figures as a guideline. Always test the material in your application and talk to an authoritative supplier.

If you must use a material with a short pot life (e.g. because it is specified or for performance reasons), consider using a Thinky Mixer, which can give you a homogeneous, air free mix in a controlled short time frame, reducing the risk of running out of pot life and enhancing the working life.

Categories: adhere academy, technical guides