In setting up a UV light curing process, the key to success is ensuring that the adhesive or other light curing material receives the correct dose or UV curing energy in order to cure as completely as possible.

In setting up a UV light curing process, the key to success is ensuring that the adhesive or other light curing material receives the correct dose or UV curing energy in order to cure as completely as possible.

Dose is the total energy arriving at the surface per unit area and is made up of the intensity of the light combined with the length of the exposure. We use the term intensity to mean the irradiance or radiant power arriving at a surface per unit area, and we measure this in W/cm² or mW/cm². The UV element of the sun’s rays reaching us in the UK (on a sunny day!) would be about 2 mW/cm², whereas the latest UV curing equipment can have intensities of up to 40,000 mW/cm².

In scientific terms, dose is measured in J/cm² and equals W/cm² x seconds.

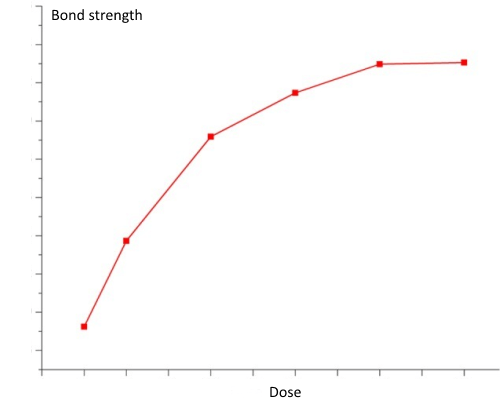

How much energy do you need to establish an optimal cure? By practical testing with your parts, understand the minimum dose needed for your application. For example, test the bond strength against increasing levels of dose (changing intensity and/or time) until the strength stops increasing. Full cure can be defined as when the addition of more curing energy no longer improves the material properties, which could also include hardness or tackiness. Establish your curing process at this minimum dose plus a safety factor (~25% recommended).

As a rule of thumb, we recommend a minimum cure intensity of about 50 mW/cm². Theoretically, to achieve the same dose, you could use lower intensity for a longer time. However, we recommend higher intensities, which as a general rule give better cure and therefore better performance – and shorter process time! It is not recommended to use very low power UV lights (or the sun!) for extended times – insufficient energy is likely to result in non-optimal or incomplete curing for most industrial grade products, which have a minimum energy level needed for activation.

We offer UV curing adhesives for many applications – we’ll be happy to work with you on yours!

Categories: adhere academy, uv curing