A recent adhere academy post discussed the modulus of elasticity of materials. Closely linked to that is another physical factor which we often quote on product data sheets: hardness.

A recent adhere academy post discussed the modulus of elasticity of materials. Closely linked to that is another physical factor which we often quote on product data sheets: hardness.

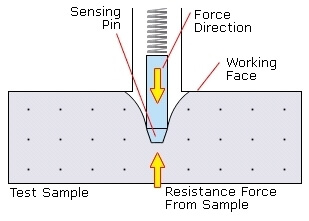

One way to define the hardness of a material is its resistance to permanent indentation. We all know that rubber balls are soft, and rock is hard, but in order to give us some quantitative numbers with which to make comparisons, we normally use measurements from an instrument called a durometer. A durometer measures the depth of an indentation in the material created by a given force. But because rubber balls and rocks are so different in their hardness, the durometer methods to measure them are different too. These different methods mean that we use different numerical scales, which we call Shore scales (named after the chap who invented the durometer).

In our data sheets, we quote durometer hardness figures from the Shore 00, Shore A and Shore D scales. There are overlaps on these scales, but they don’t necessarily have a direct linear relationship.

Shore 00 is for quite soft products (rubbers and gels), Shore A is in the medium range (harder rubbers, softer plastics), and Shore D is for harder materials (plastics).

Here are some examples, both from our portfolio and from real life:

| Material | Shore 00 | Shore A | Shore D |

|---|---|---|---|

| Chewing gum | 20 | ||

| Dymax GA-108 FIP gasket | 65 | ||

| Elastic band | 20 | ||

| Wacker Elastosil N9111 silicone adhesive sealant | 30 | ||

| Opti-tec 7020 silicone potting compound | 40 | ||

| Car tyre | 70 | ||

| Opti-tec 4200 polyurethane potting compound | 70 | ||

| Wacker Semicosil 975 TC thermally conductive silicone | 98 | ||

| Dymax 3069 plastic bonding adhesive | 55 | ||

| Dymax 3099 plastic bonding adhesive | 75 | ||

| Bone | 90 | ||

| Opti-tec 5054 epoxy adhesive | 92 |

Understanding how we quantify material hardness and make comparisons against other materials will help in material selection.

Categories: adhere academy, reference