Polyoxymethylene (POM) is a high density thermoplastic, also called acetal or polyacetal. Brand names include Delrin, Ultraform and Hostaform*. It is often used as an engineering grade plastic, especially for precision parts. POM is extremely solid, hard and stiff in a wide temperature range. It maintains its high ductility up to -40°C and has excellent abrasion and heat resistance, a low friction coefficient, good electrical, dielectrical and lubricant properties, and permits only minimal water absorption. POM is processed via injection molding, extrusion, extrusion blow molding or machining.

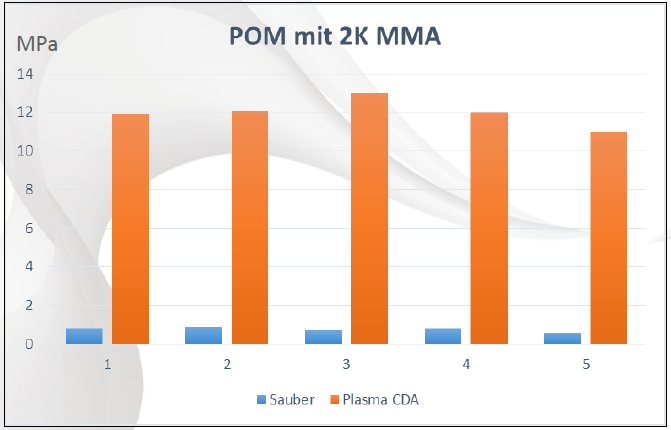

POM has a low surface energy of ~36mN/m and therefore is typically very difficult to bond. Surface treatment will improve adhesion and bonding results significantly. Our partners Relyon Plasma’s test series show that plasma treatment can increase adhesion by a factor of 10.

The chart shows the increase in bond strength of five samples – one set have been simply cleaned, the second set have been plasma treated. They were bonded with a two part methyl methacryate adhesive, although other adhesive chemistries can be tested, including epoxy structural adhesives and cyanoacrylate adhesives.

We have plasma equipment from Relyon Plasma here in our Technology Centre, suitable for both manual applications and inline processes. Combine this with one of our adhesives for successful bonding of POM or acetal plastic.

* Trademarks acknowledged

Categories: adhesives, plastics, surface preparation