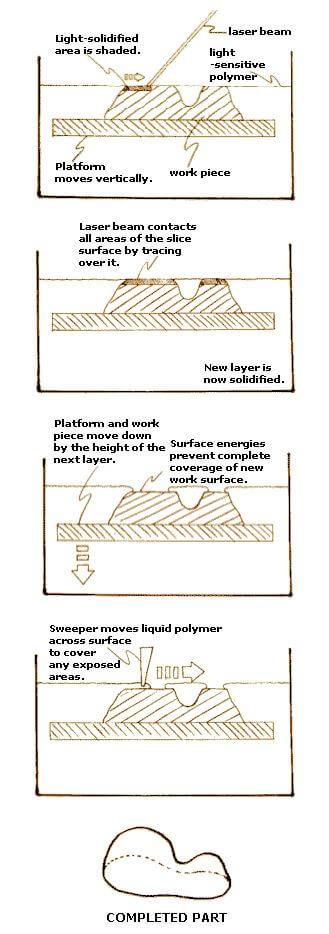

Recent developments in 3D printing (also known as additive manufacturing or rapid prototyping) have popularised the SLA (stereolithography) methodology of laser printing in a bath of UV light curable photopolymer resin. This process effectively “grows” a component in the bath so that as it is withdrawn, each successive layer is light cured. It is a process which can be many times faster than other 3D printing technologies, but does frequently need an additional UV post-cure to ensure the component attains full strength and that any excess polymer that does not drain away in the build or growth process is completed cured.

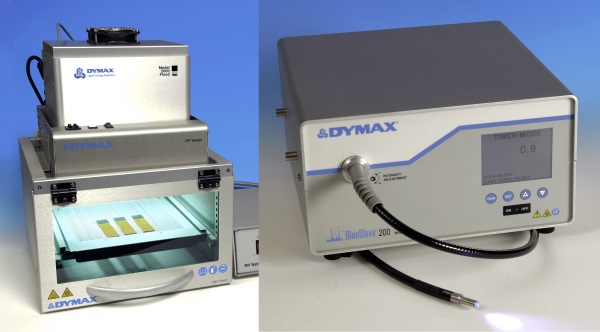

Dymax UV flood lamp and spot curing systems are ideal, both for this post-curing application, and also for subsequent re-working and repair.

Dymax UV light-curing flood lamp systems are designed for area curing or for curing multiple assemblies at once. These flood lamp models use a powerful UV light curing lamp (up to 225 mW/cm2) for fast curing over a 13 cm x 13 cm area. For rework or repair, such as curing drain-hole fills, assembling larger assemblies, or repairing cracked or broken models, the BlueWave® 200 3.0 spot-lamp system is an ideal solution. This unit is a high-intensity lamp that emits energy in the UVA and visible portion of the spectrum (300-450 nm) and is well suited for either manual or automated processes.

Dymax UV flood and spot lamps may be used as bench-top curing systems or integrated into automated production lines where they provide the industry’s most consistent light intensity over their 2000 hour bulb warranty.

Categories: 3D printing, uv curing