Light Cure Encapsulants for Electronic and PCB Assembly

About Light Cure Encapsulants for Electronic and PCB Assembly

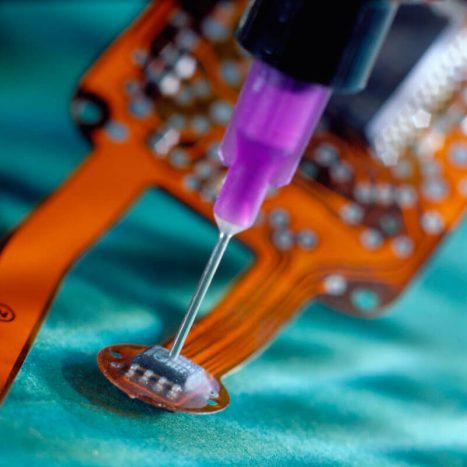

Dymax 9000 Series Encapsulants are tough, flexible UV curing electronics-grade encapsulants which are single part and cure in seconds; they cut costs and processing times associated with electronic assembly. These encapsulating materials have high ionic purity, excellent adhesion and resistance to humidity and thermal stock to effectively protect components. They contain no sharp, abrasive mineral or glass fillers to abrade fine wires, and their combination of low Tg and low modulus means low stress. Ultraviolet light-curing resins are ideal for glob top and chip on board (COB) applications and are especially suited for encapsulating IC´s on flex circuits. Clear and black grades are available along with a wide range of viscosities, from thin wicking to non-flowing gels for dam and fill.

Encapsulants – Dual Cure Systems

Dymax 9100 Series are designed with a UV/visible light and secondary ambient moisture-cure system, making them ideal for applications where shadowed areas are present. The materials produce a tough, flexible encapsulant for bare die, wire bonds or integrated circuits. They cure tack free after UV cure, so pcb assemblies can be handled sooner with less potential damage. Moisture cure is obtained after two days compared to the typical seven days with other systems, shortening the time for further handling as well as final testing and assembly. These materials are available in varying viscosities, allowing for performance and dispensing to be optimised. They are jet dispensable for more accurate placement and more efficient material usage. The cured encapsulants have high CTE and low Tg, giving flexibility and low stress.

Dymax LED protection encapsulants are also available to enhance LED performance.

Features & Benefits

- Fast cures – clear resins cure in 5 to 15 seconds

- Encapsulants for rigid or flexible circuits

- Cure on demand – only upon exposure to light

- Complete curing in seconds at room temperature

- Dual cure systems available for shadowed areas

- Precise flow control and easy dispensing

- One part – no freezing or thawing necessary

- Room temperature storage – unlimited pot life

- Low cost, compact curing systems

- Low stress

- Free of particulate fillers

- Resistance to humidity and thermal stock

- High ionic purity

Applications

- Chip on Board (COB); glob topping

- Chip on flex

- Wire bond protection

- Flexible electronics coating

- Selective pcb coating

Selector Guide

| Product | Applications | Features |

|---|---|---|

| Dymax 9014 | Chip on board, chip on flex, chip on glass, wire bond protection. EV battery management systems | Encapsulant and wire bond adhesive with a secondary moisture cure. Provides good moisture and corrosion protection. Room temperature storage. UV light curing, secondary moisture-cure capability, blue fluorescing. Excellent flexibility and increased durability and resistance on pcb’s |

| Dymax 9037-F | Chip on board, chip on flex, chip on glass, wire bond protection | Resilient chip encapsulant and wire bond adhesive designed for applications where a thixotropic, high viscosity or a damming material is required. This product cures with UV/visible light and features a secondary heat cure to address shadowed areas. This material has great flexibility, provides high moisture and thermal resistance, and fluoresces blue. |

| Dymax 9001-E-v3.0 | Thin coating, wicking and underfill | Low viscosity; can be cured in shadow areas at 120°C |

| Dymax 9001-E-v3.1 | Glob top | Medium viscosity; can be cured in shadow areas at 120°C |

| Dymax 9008 | Encapsulating on flex/polyimide | High adhesion to polyimide to – 40°C; flexible |

| Dymax 9101 | Chip on board, chip on flex, chip on glass, wire bond protection | Low viscosity; secondary moisture cure |

| Dymax 9102 | Chip on board, chip on flex, chip on glass, wire bond protection | Medium viscosity; secondary moisture cure |

| Dymax 9103 | Chip on board, chip on flex, chip on glass, wire bond protection | High viscosity; secondary moisture cure; dam and fill applications |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

- Last updated: November 2022

- Version: 5.6

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.