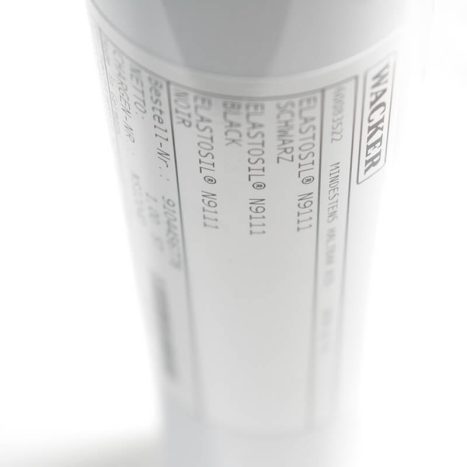

WACKER Silicone Adhesive Sealants

About WACKER Silicone Adhesive Sealants

Also available to buy online at ![]()

Cost-effectiveness and sustainability are key considerations when it comes to bonding and sealing. Bonding with silicone adhesive sealants has decisive advantages over traditional mechanical joining technologies in terms of handling, functionality, durability and cost-efficiency. Single part RTV (RTV-1) silicones are one-step, ready-to-use adhesives and sealants. They crosslink automatically when exposed to air humidity at room temperature. These silicone rubbers are either room-temperature-vulcanizing (RTV) or one-part heat-curing systems. Both systems are exceptional for their processing properties.

Another important criterion for selecting the best product is the flow property – we offer you RTV-1 silicones with a consistency ranging from free-flowing to non-sag pastes.

WACKER silicone adhesive sealants can be applied easily and economically either manually or with automated dispensing equipment. Compared to mechanical joining methods, adhesive sealants significantly reduce not only the quantity of parts (e.g. screws, rivets, etc.) but also the number of process steps. Hence, silicone adhesive sealants help to reduce process cycle time.

RTV-1 silicones find many applications in form-in-place (FIP) gaskets and cure-in-place (CIP) gaskets.

Features & Benefits

- Bonding efficiency: An adhesive sealant acts as a bonding agent and sealant at the same time. The need for additional mechanical safeguarding measures often becomes obsolete.

- High joint reliability: Thanks to the good electrical insulating properties of silicones, different metals can be bonded without the risk of galvanic corrosion.

- Joint stress relaxation: Thanks to their low Young’s modulus, silicone adhesive sealants effectively compensate thermomechanical loads resulting from substrates with differing coefficients of thermal expansion.

- Versatile applicability: Silicone adhesive sealants have a high ability to bond dissimilar materials, usually without the need for primers.

- Temperature resistance: Permanently elastic properties from -45°C to over approx +180°C; Specialised types remain elastic even at 250°C and briefly tolerate even higher temperature spikes

- Chemical resistance: Permanent resistance to aqueous solutions, dilute acids and bases as well as solvents

- Resistance to radiation: Can be exposed to electromagnetic radiation emitted by sources from microwaves to UV even at higher doses

- Vibration and mechanical strength: Processing tolerances for joint parts are effectively compensated and vibrations are effectively dampened thanks to its high elasticity

- Minimal moisture absorption: The hydrophobic, water-repellent surface of silicones offers excellent protection against moisture

Specifications

| Wacker Silicone Primers and Inhibitors | |

|---|---|

| Product | Characteristics |

| Primer G 790-TF | General purpose adhesion-promoting primer for use with addition-curing silicone rubbers. Toluene-free, solvent-based material which is suitable for various coating techniques like dipping, brushing or spraying. |

| Inhibitor PT 88 | Can be added to RTV-2 addition cure silicones to extend the pot life and cure time to suit the processing requirements of your particular application. |

For additional specifications, view our selector guide.

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Dispensing Systems

We supply the equipment necessary to dispense silicones, including manual silicone dispensing guns and complete automated silicone dispensing systems. Get in touch with our team to discuss the best options for your production environment.

See how one of our customers improved their manufacturing process and quality in this silicone dispensing Case Study:

|

Automated dispensing helps security manufacturer increase throughput and quality

GJD Manufacturing switched to an automated method of dispensing silicone for sealing a plastic lens to aluminium housing. By doing this, they improved the throughput and quality of their white-light and infrared LED illuminators for the security industry. |

|

Automated dispensing system increases lighting manufacturer’s throughput fourfold

Automotive and marine lighting manufacturer, Venta Global, needed a material that offered high levels of environmental protection as well as a method of automating their gasking process. Choosing to implement Wacker N2199 and a dispensing robot into their process, Venta Global significantly improved the performance and throughput of their lighting assemblies. |

- Last updated: February 2024

- Version: 5.6

Semicosil® and Elastosil® are registered trademarks of Wacker Chemie AG. Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.