WACKER Silicone Encapsulants and Potting Compounds

About WACKER Silicone Encapsulants and Potting Compounds

Also available to buy online at ![]()

Silicone encapsulants from WACKER are effective for the potting and encapsulation of electronic control units, sensors, printed circuit boards, semiconductor devices or microchips. Potting or encapsulation provides efficient protection from the environment, assisting in reliable operation over the lifetime of electronic devices.

We offer one and two component WACKER products for potting and encapsulation applications. Silicone gels offer minimal thermal stress on sensitive parts and ensure that the device will work properly even when exposed to extreme temperature fluctuations or strong vibrations. For sensor applications, gels characterised by particularly low volatility and low bleed are becoming increasingly important.

Features & Benefits

- High thermal shock resistance

- Low shrinkage

- Good adhesion including to polymer housings

- Low outgassing

- Low uncured-silicone bleed

- Formulations from Shore 00-55 to A80

- Transparent versions available

Specifications

For additional specifications, view our selector guide.

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

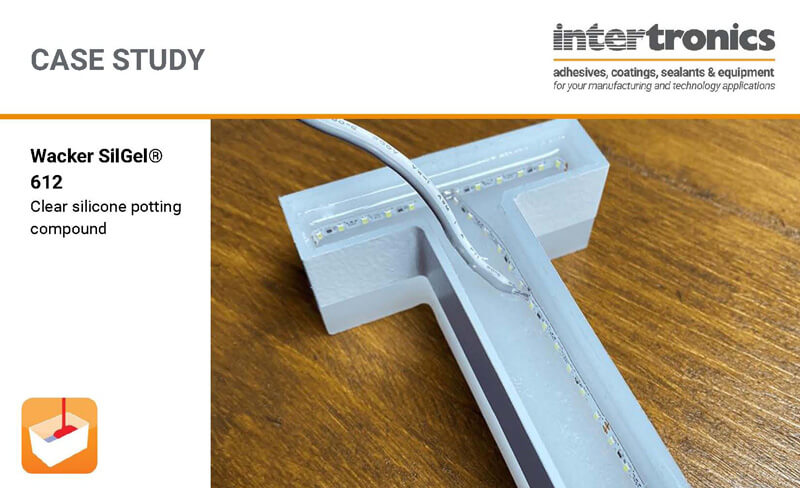

See how our Wacker SilGel 612 works as part of a real application in these Case Studies:

|

Potting LED strips for outdoor signage made easy with silicone gel

A UK manufacturer of outdoor signage and lighting products was seeking to encapsulate their LED strips to protect them from environmental damage, whilst maintaining a desirable aesthetic in the finished product. Wacker SilGel 612 fit the bill. |

|

Application Insight – Electronics Assembly Potting

Potting PCBs within wireless remote control devices using Elastosil RT 601. |

- Last updated: January 2024

- Version: 2.7

Semicosil®, Elastosil®, and SilGel® are registered trademarks of Wacker Chemie AG. Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.