Opti-tec 5054-1 High Temperature Epoxy Adhesive

OPT 5054-1

About Opti-tec 5054-1 High Temperature Epoxy Adhesive

Also available to buy online at ![]()

Opti-tec™ 5054-1 high-temperature epoxy adhesive is a two-component, low viscosity, heat curing epoxy. It is formulated for very high-temperature resistance and can operate up to 350°C for short periods. Its structure gives the material outstanding environmental resistance including superheated steam at 135°C. Opti-tec 5054-1 finds applications in fibre optic terminations where superior thermal and environmental resistance is required. It has passed ISO 10993-5 for medical device applications.

Opti-tec 5054-1 has a thixotropic, high viscosity version – Opti-tec 5054-T.

Features & Benefits

- Can withstand high temperature steam autoclaving and operate for short periods up to 350°C

- Very long pot life of 12 hours after mixing

- High surface energy low viscosity allows it to readily wet and wick between optical fibres

- Strong adhesion to most materials used in fibre optics and optics, including metals, ceramics, glass and most plastics

- Low shrinkage on cure, reducing internal stresses within the bond. It is therefore suitable for multiple fibre assemblies.

- Excellent impact and thermal shock resistance, with low internal stresses

- High glass transition temperature – excellent high temperature performance and creep resistance

- Very high resistance to moisture, vapours and most chemicals

- Low outgassing and low vapour pressure, making it an ideal sealing material for electronic and optical applications

- Used for Telcordia GR-326-CORE compliant assemblies (General Requirements for Singlemode Optical Connectors and Jumper Assemblies – formerly Bellcore), where its high Tg and environmental robustness allow the termination to meet the specification. Note: optimal cure schedule required.

- When cured, is considered non-cytotoxic and meets the requirements of the Elution Test, ISO 10993-5. Further ISO 10993 and USP Class VI qualification pending.

Applications

- Fibre optic terminating

- Endoscope manufacture and repair

- Optoelectronics

- High temperature, high performance bonding

- Electronic sealing

- Medical devices and instruments

- Unitising voice coils

Specifications

Part number change: as of version 6.0, April 2021, the part number of this product changed from Opti-tec 5054 to Opti-tec 5054-1. This is due to an unavoidable change in a formulation component. This change does not affect the product data-sheet specifications. The new formulation has passed internal testing and is deemed to be equivalent.

| Typical properties | Opti-tec 5054-1 | |

|---|---|---|

| Mix ratio | 100:85 resin to hardener | |

| Mixed viscosity | 500 – 1000 cps | |

| Colour | Amber | |

| Surface tension | 40-44 mN/m | |

| Pot life | 12 hours @ 23°C | |

| Cure schedule | Bondline temperature 120°C 150°C |

Time 30 minutes 5-10 minutes |

| Note: Optimal cured properties are achieved by curing for 5 minutes at a bondline temperature of 150°C. Whilst lower cure temperatures are quoted, they are not recommended for best performance. | ||

| Optimum cured properties (5 minutes @ 150°C) |

||

| Glass transition temperature (Tg) | >140°C | |

| Density | 1.20 | |

| Hardness | Shore D 92 | |

| Temperature range | -60 to 250°C | |

| Modulus | 2 GPa | |

| Shrinkage on cure | <3.5% | |

| CTE | 55 ppm/°C | |

| Lap shear (Al/Al) | 11 MPa (@ 23°C) | |

| Shelf life | 12 months in original sealed containers | |

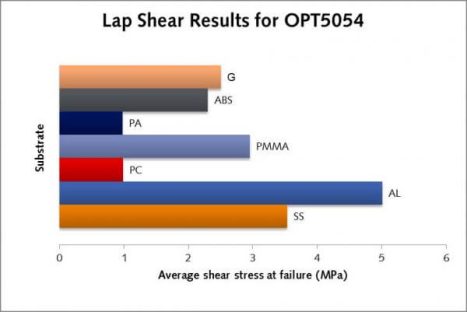

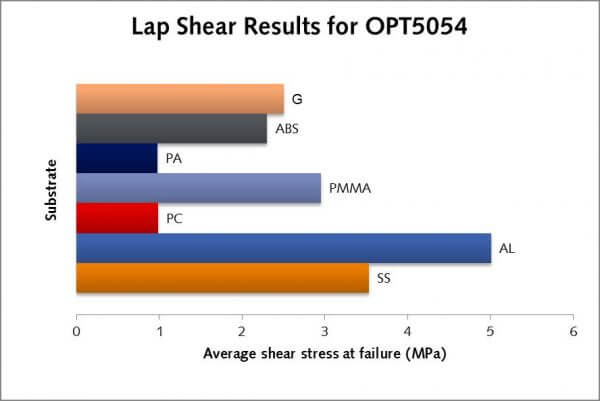

| Adhesive bonded joints | Sheer stress at failure (MPa) | Mode of failure |

|---|---|---|

| Stainless steel | 3.5 | Adhesion |

| Aluminium 6082 T6 (AL) | 5.0 | Adhesion |

| Polycarbonate (PC) | 1.0 | Cohesive substrate |

| PMMA | 3.0 | Cohesive substrate |

| Nylon 6/6 (PA) | 1.0 | Adhesion |

| ABS | 2.3 | Cohesive substrate |

| Glass (G) | 2.5 | Cohesive substrate |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

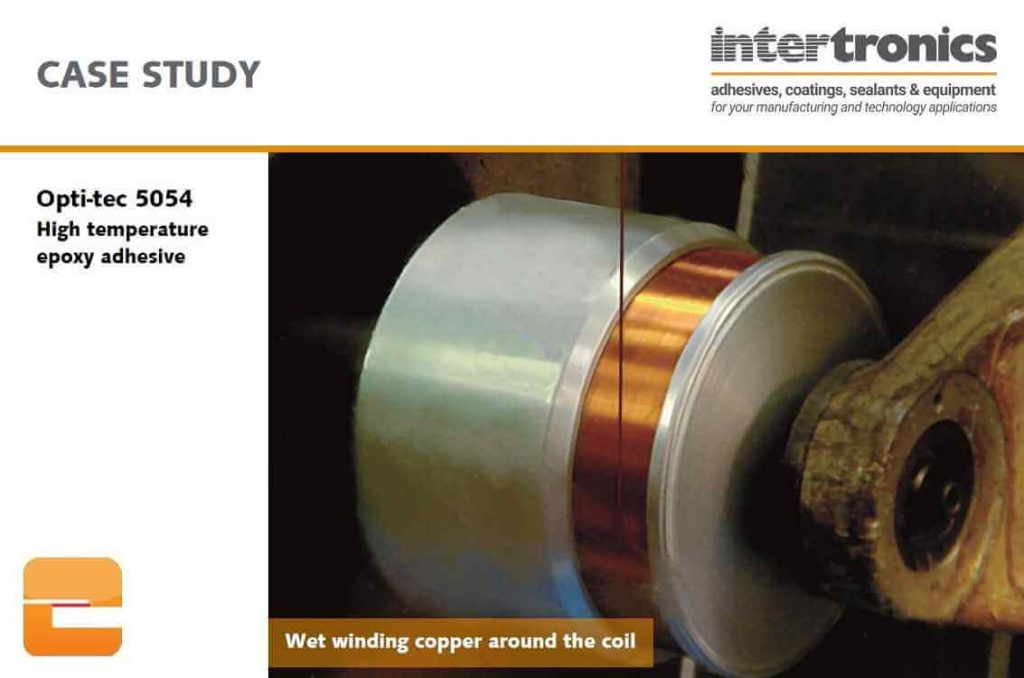

See how OPT 5054-1 works as part of a real application in this Adhesive Case Study:

|

Using Opti-tec 5054 to aid in high power and high performance speaker coil assembly processes

Speaker coil assembly required a low viscosity adhesive with resistance to high temperatures and extended pot life. |

Ordering Information

Packaging

OPT 5054-1 is available in twinpacks or in bulk.

The twinpack sachet is a clear film sachet, with the resin and hardener separated by a removable clip and rail divider. Click here for twinpack mixing instructions.

Standard twinpack size is 4g total weight. Opti-tec 5054-1 twinpack sachets are packaged in quantities of 5, sealed into a protective aluminium foil pouch.

| Part number | Description |

|---|---|

| OPT5054-1-4G |

5 x 4 twinpack sachets |

| OPT5054-1-500G |

500g kit |

Storage: Store in the original unopened containers under cool dry conditions between 15° and 25°C.

Medical devices: It is the user’s responsibility to determine and validate the suitability of this adhesive in the intended medical device. This adhesive has not been tested for prolonged or permanent implantation, and is only intended for use in short term (28 days) or single-use disposable device applications. Intertronics does not authorise its use in long-term implant applications.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 6.9

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.