Opti-tec 4200 Optically Clear Polyurethane Encapsulant & Potting Compound

About Opti-tec 4200 Optically Clear Polyurethane Encapsulant & Potting Compound

Also available to buy online at ![]()

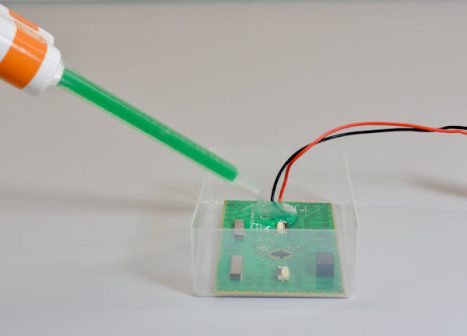

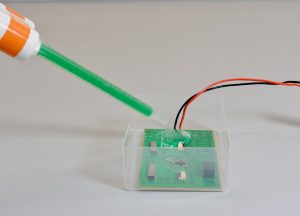

Opti-tec™ 4200 is a clear, water-white polyurethane resin designed for the encapsulation of electronics, LEDs, electrical products and other items where high transparency and aesthetics are important. Opti-tec 4200 optically clear potting compound has excellent non-yellowing colour stability, due to the incorporation of both UV resistant base materials and the addition of UV stabilisers and antioxidants.

Opti-tec 4200 is used for a range of applications from high value LED panels to decorative giftware (e.g. flower impregnation). It is also an excellent resin for the doming of badges, labels and decals.

Opti-tec 4200 is available in a translucent milky-white version (Opti-tec 4220).

Features & Benefits

- Clear, water-white, non-yellowing

- Excellent long term UV stability

- Scratch and mark resistant

- Non-toxic

- Easy to mix and process

- Very low viscosity

- Excellent penetration and air release properties

- Low shrinkage

- Low exotherm

Applications

- Protection of LEDs – LED bars, LED arrays, luminaires

- LED potting or LED encapsulation

- Electronics potting

- Dome coating of labels and badges

- High quality, clear casting

Specifications

| Typical properties | Mixed | Resin | Hardener |

|---|---|---|---|

| Colour | Clear | Clear | Clear |

| Specific gravity (g/ml) | 1.11 | 1.06 | 1.16 |

| Viscosity mPa.s @ 25°C | 600 | 600 | 600 |

| Mix ratio by weight | 0.92:1 | ||

| Mix ratio by volume | 1:1 | ||

| Curing* | |||

| Pot life | 10 minutes | ||

| Gel time | 20 minutes | ||

| Tack free cure | 40 minutes | ||

| Minimum cure schedule | 36 hours @ 20-25°C 4 hours @ 40°C 2 hours @ 60°C |

||

| * typical values – will vary according to mass, film thickness and application. Higher cure temperatures will result in greater cure shrinkage and exotherm. | |||

| Cured properties | |||

| Shore hardness | A75 | ||

| Operating temperature (application & geometry dependent) | -55 to +120°C | ||

| Thermal conductivity | < 0.21 W/mK | ||

| Tensile strength | ~ 15 mPa | ||

| Elongation at break | 100% | ||

| Coefficient of linear expansion | 100-150 pp/m°C | ||

| Volume resistivity | < 1.3 x 1012 ohm.cm | ||

| Surface resistivity | < 1.4 x 1012 ohm | ||

| Dielectric strength | 20 kV/mm | ||

| Water absorption | 1.17% (30 days @ 25°C) | ||

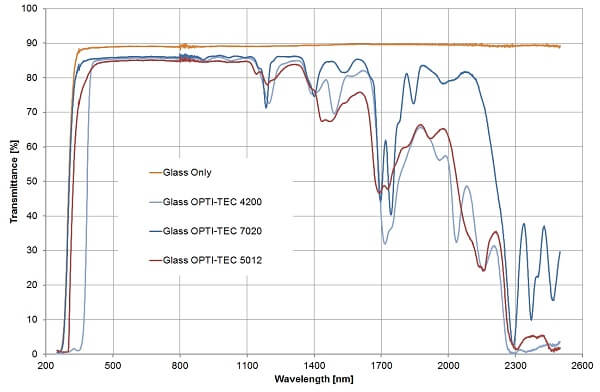

| Refractive index | 1.47-1.48 | ||

| Opti-tec 4200 is RoHS compliant and contains 0% REACH SVHC | |||

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

As of 24 August 2023, adequate training is required before industrial or professional use of this product.

Ordering Information

Packaging

Opti-tec 4200 is available in convenient side-by-side double syringe cartridges, twinpack sachets and bulk packaging.

Click here for twinpack mixing instructions.

For best results, store away from strong oxidising agents, strong acids and strong bases. Store in a cool, well-ventilated area. Keep container tightly closed and keep in original packaging.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 3.3

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.