THINKY ARV-310P Mixing and Vacuum Degassing Machine, Planetary Centrifugal Vacuum Mixing

THI ARV-310P

About THINKY ARV-310P Mixing and Vacuum Degassing Machine

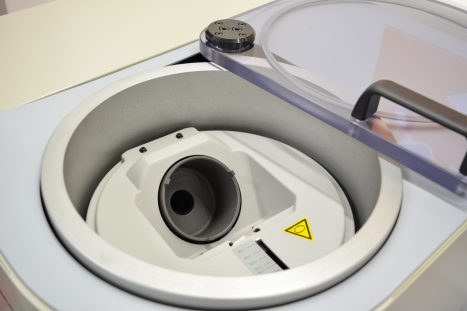

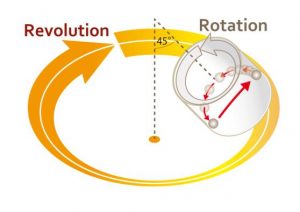

The THINKY ARV-310P is an industrial non-contact “planetary” mixer suitable for all engineering compounds. This vacuum degassing machine mixes, disperses and degasses up to 310g of material to high levels in seconds to minutes, removing any micro-bubbles using an integral vacuum function. Mixing takes place in a sealed or lid-less container such as a jar, beaker, syringe tube or cartridge. The non-contact mixing principle makes it possible to formulate compounds from very small amounts such as 0.5ml to large production scales.

Ordinarily, when manually degassing using a vacuum, caution must be taken to prevent foaming and messy overflows. The THINKY ARV-310P is able to avoid this issue as the mixed material is forced to the sides of the container during the simultaneous mixing procedure. This mitigates the potential requirement for deep cleaning workspaces after use.

“The THINKY mixer and Fisnar robotic dispenser enabled us to achieve high accuracy process windows, due to the consistency of the mix and the positioning of the dispense, which are both critical to the light output.” – Carl Withers, Plessey Semiconductors

Features & Benefits

- Mix material to be homogeneous and bubble-free in seconds to minutes

- Non-invasive

- No cleaning between batches

- 4.3-inch touch panel enables easy command input

- Mix in your product container

- Up to 20 recipes containing 5 steps can be registered

- Degas and remove bubbles at the same time

- Real-time status and progress displayed during operation

- Multi-step mixing

- Process from 0.5ml of material

- RS-232C connection ensures better traceability through an external terminal

- Consistent results achieved through all digital controls

- Ability to mix from low viscosity to semi-solid materials

- Fast mixing

- Hands-free mixing

Applications

|

|

|

Our customers use the mixer to formulate and mix a multitude of different products including:

- adhesives

- sealants

- moulding compounds

- lubricants

- slurries

- coatings

- inks

- paints

- abrasives

- bio-chemicals

- cements

- medical compounds

- cosmetics/personal care materials

- detergents

- conductive pastes

- dental materials

- foods

- any other materials which are hard to mix, degas, or wet

Specifications

| Specification | |

|---|---|

| Method | Vacuum type propellerless rotation and revolution mixing method |

| Range of operation time | From 00 minutes 00 seconds to 30 minutes 00 seconds (The total operation time can be set at maximum 30 minutes in units of 1 second) |

| Revolution speed | Maximum 2000 rpm |

| Rotation speed | Maximum 1000 rpm |

| Number of programmes | 20 memories (five steps can be registered in each) |

| Container | 300ml and 150ml |

| Maximum mixing volume – Atmospheric pressure | 300ml container: 250ml / 310g 150ml container: 120ml / 310g |

| Maximum mixing volume – Vacuum operation | 300ml container: 200ml / 310g 150ml container: 100ml / 310g |

| Vacuum chamber | Rotary part vacuum chamber system |

| Working environmental conditions | -10 to 35°C 35 to 85% RH (no condensation) Altitude lower than 2000m |

| Dimensions | H 450 x W 555 x D 645mm |

| Weight | Approximately 90kg |

| Power supply | Single-phase AC 100V +/- 10% 50Hz / 60Hz |

| Power consumption | On standby: approximately 50 VA During operation: maximum 1200 VA |

| Display unit | Touch panel (4.3 inches) |

| Communication function | Data collection function (Traceability function) Operation start and stop Recipe editing and saving Using an external terminal |

| Other | Real-time display of rpm during operation Ability to assign recipe names |

Other Information

See how the THINKY ARV-310 works as part of a real application in these metering and mixing Case Studies:

| Material mixing and dispensing prove key for LED production quality

Plessey Semiconductors transitioned to a full production phase of their LEDs by using automated mixing and dispensing equipment. |

|

|

Degassing times reduced by up to 90%

For a manufacturer of compound semiconductors, the process of hand mixing the multi-part resins in which to encapsulate them was causing an inconsistent, labour intensive final product. |

|

Manufacture of NMC electrodes for lithium-ion batteries with high active material content

The manufacture of electrodes is a crucial step in the production of Lithium-ion batteries, especially the mixing and coating processes, which are involved. Using a ARV-310, the Technical University of Munich homogeneously mix NMC inks in a few minutes. |

|

Getting to know THINKY Mixers

Download a presentation which describes how THINKY Mixers work, and what benefits they can deliver to you. |

Our Technical Bulletins page has links to:

- Technical Bulletin: Vacuum Mixing & Degassing

All Downloads

Ordering Information

| Part number | Description |

|---|---|

| THIARV-310-P | THINKY Mixer ARV-310P Mixing and Vacuum Degassing Machine Includes 3 x THI300ML-HOLE 300ml jars, 1 x THI150ML-HOLE 150ml jar and 1 x THI250AD-201 adapter |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 5.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.