Dymax UV Light Curing Adhesives for Electronics Assembly

About Dymax UV Light Curing Adhesives for Electronics Assembly

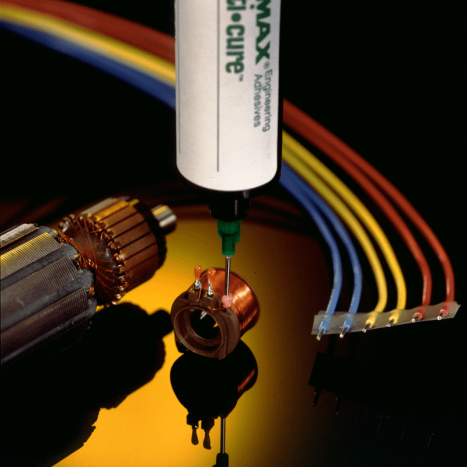

Dymax UV adhesives cure in seconds when exposed to high intensity UV light, and find many applications as adhesives for electronics assembly. The “on demand” cure feature of these resins means no rework as a result of adhesive migrating onto solder pads or through holes. Dymax adhesives for electronic assembly are ideal for bonding heat sinks and heat sensitive components, wire and component tacking, strain relief of large parts and securing hand inserted components prior to wave soldering. Single part UV light curing adhesives can give productivity gains over two part systems like epoxies, and slower curing chemistries like silicones.

These one-part, solvent-free adhesives are electrically insulating, and are particularly useful for:

- Wire tacking and component ruggedisation

- BGA and leadless component support

- Strain relief, supporting larger electronic components

- Thermal management, heat sink bonding

- Shallow potting

Features & Benefits

- Fast “instant” cures

- Single part formulations

- Cure on-demand – only upon exposure to UV light

- Excellent adhesion

- Precise and easy dispensing

- Room temperature storage – unlimited pot life

Selector Guide

Product data sheets available on request.

Electronics adhesives

These adhesives provide optimal circuit protection. Their “on-demand” cure feature makes them ideal for manual applications such as wire tacking and coil termination, where optimal placement and immediate strength is critical.

| Product | Applications | Features |

|---|---|---|

| Dymax 9-911-REV-B DYM 9-911-REV-B |

Wire tacking/coil termination | On-demand cure for optimal positioning; easily dispensed by hand; exposed areas cure in seconds for immediate strength; shadowed areas may cure with heat over time |

| Dymax 910 DYM 910 |

Wire and parts tacking; strain relief; unitising | Flexible; good adhesion; mechanically removable |

| Dymax 914-A DYM 914-A |

Wire tacking on PCB’s; for manual and fully automated dispensing systems | Good insulation qualities; shock absorbing; deep cure capability; bonds well to porous surfaces; rapid cure speed |

Component ruggedising

Dymax component ruggedizing and staking materials are engineered to hold critical components, such as Ball Grid Arrays (BGA) and Video Graphics Arrays (VGA), for secondary processes or for long-term reliability. Each material helps enhance shock and vibration resistance of electronic assemblies.

| Product | Applications | Features |

|---|---|---|

| Dymax 9422-SC DYM 9422-SC |

Reinforcing fine pitch or leadless components; underfill replacement; staking | Fast, room-temperature cure; adhesion to various PCB substrates; low modulus for reducing stress on board components; highly thixotropic for minimal movement after dispense; See-Cure adhesives appear blue when dispensed and become clear for easy verification of cure; halogen-free |

| Dymax 9309-SC DYM 9309-SC |

Reinforcing fine pitch or leadless components; underfill alternative; shock absorption | Tack-free cure; compatible with both needle and jet dispensing equipment; adhesion to various PCB substrates; reduces stress on board components; highly thixotropic for minimal movement after dispense; See-Cure adhesives appear blue when dispensed and become clear for easy verification of cure; halogen-free |

Potting & sealing

Dymax light cure UV potting materials cure tack-free in seconds upon exposure to UV/Visible light. Each potting compound is engineered to bond different substrates, offering tenacious adhesion to plastics and metals. UV potting resins reduce waste from off-ratio mixing and are free from isocyanates and heavy metals. Processing in seconds eliminates fixtures, jigs, racks, and ovens to increase space and lower total inventory costs.

| Product | Applications | Features |

|---|---|---|

| Dymax 921 series DYM 921 |

Potting; ruggedising heavy components | Urethane acrylate; light cure in seconds; secondary heat cure; one part, no mixing is required; multiple viscosities; visible light cure for maximum cure depth; adhesion to filled plastics including PBT/Valox® |

Thermal management

Dymax Multi-Cure® thermal interface materials may be cured with light, heat, or activator. Most applications utilise a combination of these methods for optimal cure speed. Light cure allows for exposed areas to cure immediately, fixturing parts in place so the activator or heat can continue curing in shadowed areas without interruption to process flow.

| Product | Applications | Features |

|---|---|---|

| Dymax 9-20801 DYM 9-20801 |

Adhesive paste | Thermally conductive; 1.2 W/mK; UV/Visible light cure for exposed areas in seconds; activator or heat cure shadowed areas; one part; solvent free |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

Our Technical Resources page has links to:

All Downloads

- Last updated: November 2022

- Version: 4.7

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.