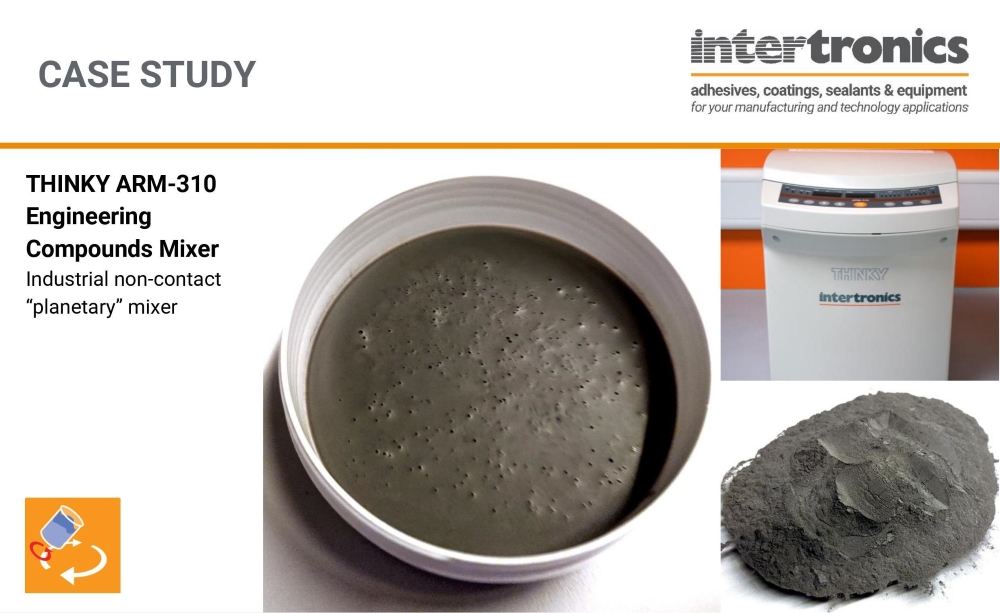

THINKY ARM-310 Engineering Compounds Mixer

THI ARM-310

About THINKY ARM-310 Engineering Compounds Mixer

The THINKY ARM-310 engineering compounds mixer provides consistent mixing results with simple operation and no mixing implements to clean. Like the rest of our THINKY mixing machines, the THINKY ARM-310 uses planetary centrifugal motion to quickly and homogeneously disperse engineering compounds such as adhesives, sealants, lubricants, cosmetics, or pharmaceuticals. Mixing takes place in removable containers, meaning that there is no mess to clean up after mixing, thereby saving valuable time and avoiding cross-contamination.

Upgrade your mixing process to one that is automated, works in seconds to minutes, and provides the same mixing results every time, with a fast return on investment compared to manual mixing. Mixing programs can be stored in the mixer’s memory for easy operator use.

For compounds which require degassing or vacuuming, please see the other mixers in our THINKY range.

Features & Benefits

- For materials with various densities and viscosities, or dry particle mixing

- Non-invasive processing ends the risk of cross-contamination between batches

- Processes in seconds to minutes

- Processes in your containers such as jar, barrel, cartridge, syringe or tube

- Processes from 0.5ml – save valuable material wastage

- Re-mixes separated materials to prolong shelf life

- No damage to material unlike the use of rollers, mixing blades or propellers

- No unit cleaning between batches, which eliminates non-productive work

- Cooling unit available for temperature control in high-usage applications

Specifications

| Specification | |

|---|---|

| Dimensions | H 390 x W 300 x D* 340mm (*With freight locks: 365mm) |

| Weight | Approximately 18kg |

| Maximum mixing volume | 300ml container: 250ml / 250g net (310g gross) 150ml container: 120ml / 200g net (300g gross) |

| Memory | 5 stored recipes, each with up to 5 sequential time and RPM steps |

| Working environment conditions | 10 to 35ºC, 35-85% relative humidity (non-condensation) Indoor use only Within 2000m altitude |

| Timer setting range | 0 to 30 minutes in 1 second increments |

| Revolution speed | Maximum 2,000 RPM |

| Rotation speed | Maximum 800 RPM (1/2.5 of revolution speed) |

| Noise | During operation (average): 63 dB(A) |

| Safety features | Door sensor, revolution sensor, vibration sensor |

| Power supply | Single-phase AC 230V +/- 10, 50Hz |

| Power consumption | On standby: approximately 50 VA, during operation: maximum 900 VA |

Other Information

|

Production of a Homogeneous Feedstock for LMM 3D Printing Process

Seeking a way to homogeneously mix feedstock for their Lithography-based metal manufacturing (LMM) process, Pforzheim University chooses a THINKY ARM-310 mixer to effectively mix metal powder into a high viscosity, photosensitive polymer. |

All Downloads

Ordering Information

| Part number | Description |

|---|---|

| THIARM-310 | THINKY ARM-310 planetary centrifugal mixer |

| THIENS-10CE | THINKY mixer cooling system attachment |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 2.7

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.