Dymax BlueWave® QX4™ LED UV Spot Curing Lamp

DYM88828

About Dymax BlueWave® QX4™ LED UV Spot Curing Lamp

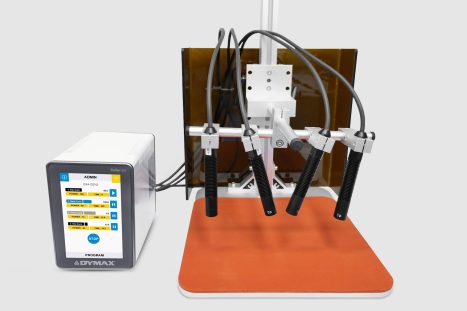

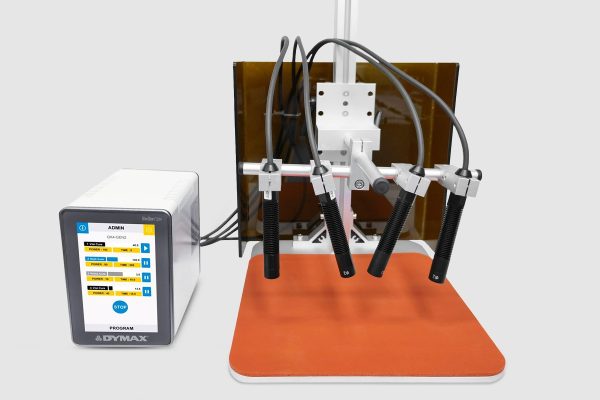

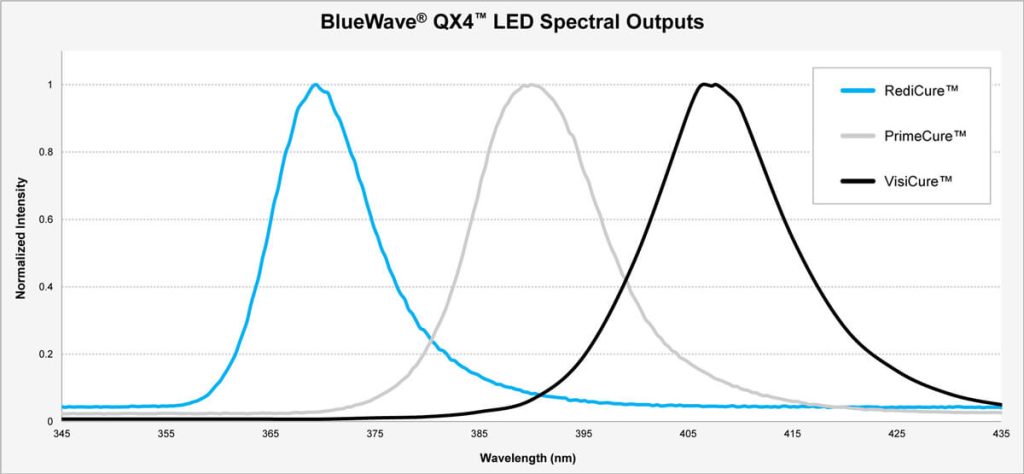

The Dymax BlueWave QX4 V2.0 high intensity LED UV spot curing lamp features all the benefits of LED curing technology in a small, versatile unit. This system comprises a controller with a foot switch and up to four LED heads. The LED heads are available in 365nm, 385nm, and 405nm and can be outfitted with 3mm, 5mm, or 8mm diameter focusing lenses. LED heads and focusing lenses can be used in any combination and can be controlled through the system’s variable mode, a feature that allows each head to be operated independently and individually programmed for intensity and cycle times. Individual exposure times and intensity settings can be set to 1% increments from 10-100% for each LED head, giving users maximum curing flexibility.

Peak intensity is up to 22,900 mW/cm2 of curing energy. The BlueWave QX4 V2.0 is capable of curing compatible adhesives, coatings, sealants and other light-curable materials quickly – often in a few seconds. Full output specifications are detailed in the product data sheet.

In addition to the curing flexibility, the BlueWave QX4 V2.0 also features an easy-to-use control interface that allows flexibility in setup and use of the unit. The unit can be activated by foot pedal or by PLC interface, allowing it to be easily incorporated into automated systems.

Control up to four LED wands independently for curing flexibility

Control up to four LED wands independently for curing flexibility

Features & Benefits

| Features | Benefits |

|---|---|

| One controller with up to four LED heads | · Provides maximum application flexibility |

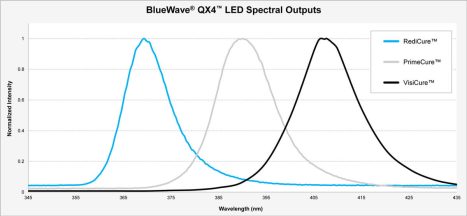

| LED heads available in 365nm (RediCure), 385nm (PrimeCure), or 405nm (VisiCure) wavelengths | · Compatible with a variety of UV and visible light-curable materials · Wavelength flexibility allows co-optimization of adhesive and curing system for best cure · Units can be custom configured to your curing requirements |

| Variable mode allows each LED head to be programmed and operated independently | · Compatible with a variety of UV and visible light-curable materials · Wavelength flexibility allows co-optimization of adhesive and curing system for optimal cure · Units can be custom configured to your curing requirements |

| Interchangeable/Replaceable focusing lenses in 3mm, 5mm and 8mm diameters | · Allows tailoring of the unit to your curing requirements |

| Instant on-off | · No warm-up period · More energy efficient |

| Efficient LED-head temperature management | · Maximized continuous operation without overheating · Comfortable hand-held operating temperature · Temperature monitoring assures maximum LED life |

| PLC interface | · Easily incorporated into automated systems |

System Components

Complete BlueWave QX4 V2.0 systems feature:

- a controller/power supply with a foot switch

- up to four LED heads/wands

- three available lens diameters for each head/wand

The length of the head/wand with the direct wired cable is 1.0m (end to end). All components are available separately to enable upgrading and experimentation.

Specifications

| Specification | RediCure™ | PrimeCure™ | VisiCure™ |

|---|---|---|---|

| Output Frequency | 365nm | 385nm | 405nm |

| Intensity Output* | 16.9 W/cm2 | 22.9 W/cm2 | 22.0 W/cm2 |

| Power Supply Input | 100-240 V ~2A / 50/60 Hz | ||

| LED Timer | 0.1 to 999 seconds | ||

| LED Activation | Footswitch, front panel, or PLC | ||

| Cooling | Natural convection | ||

| Controller Dimensions | 9.35cm x 14.75cm x 13.74cm (W x D x H) | ||

| Weight | Controller: 1.00kg / Head: 0.13kg | ||

| Unit Warranty | 1 year from purchase date | ||

| Operating Environment | 5-40ºC, non-condensing | ||

*Measured with a 3mm lens using a Dymax ACCU-CAL 50-LED Radiometer, in spot mode using the BlueWave QX4 V2.0 Integrated Optic Adapter

Other Information

|

Top Tips for getting the best from your UV curing process

Read through our easy-to-follow guide on UV curing to maximise your processes productivity. |

Find out more about the technology behind the QX4 by reading our technical bulletins and white papers:

- Sustainability Benefits of LED UV Curing

- UV Curing and Tack-Free Cures

- Achieving Better Process Controls with Light Cure Technology

- Advances in Light Curing Adhesives and Coatings Lead to Process and Quality Benefits in Electronics Manufacturing

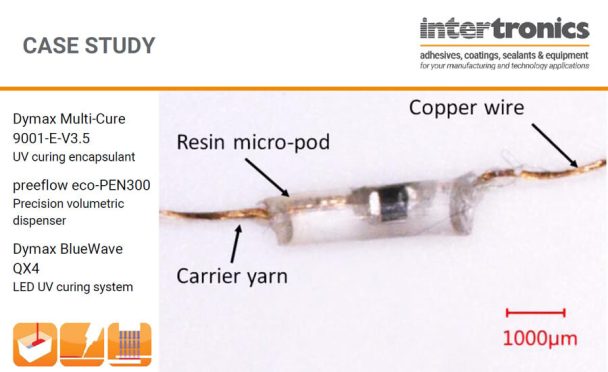

See how the Dymax QX4 works as part of a real application in this UV curing adhesive and equipment Case Study:

|

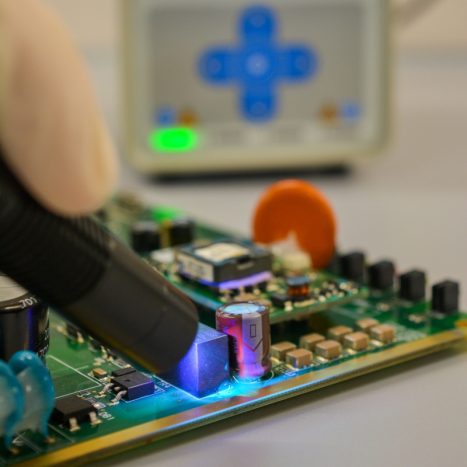

Electronic Textiles Development Benefits from UV Curing Resin and Precise Dispensing The Advanced Textiles Research Group at Nottingham Trest University has been developing electronic textiles to add functionality to materials and garments. Part of the process involves encasing microchips within a polymer micro-pod in order to protect them from mechanical and chemical stresses during everyday use. |

All Downloads

Ordering Information

Purchase a Controller and up to four LED head/wands. Each LED head/wand requires a lens. Minimum configuration is 1 x controller, 1 x LED head/wand and 1 x lens.

System Components

| Part number | Description |

|---|---|

| DYM88828 | BlueWave QX4 Controller / Power Supply |

| DYM5028 | Foot Switch |

| DYM88807 | QX4 2.0 RediCure™ 365nm LED Head/Wand |

| DYM43162 | PrimeCure™ 385nm LED Head/Wand |

| DYM88809 | QX4 2.0 VisiCure™ 405nm LED Head/Wand 2.0 |

| DYM43164 | 3mm Lens |

| DYM81206 | 5mm Lens |

| DYM81207 | 8mm Lens |

Connection Cable Extensions

| Part number | Description |

|---|---|

| DYM41563 | 0.5m |

| DYM41565 | 1.5m |

| DYM41566 | 2.0m |

Let’s start by talking about your application

- Last updated: June 2024

- Version: 3.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.