Dymax UV Curing Glass Bonding Adhesives

About Dymax UV Curing Glass Bonding Adhesives

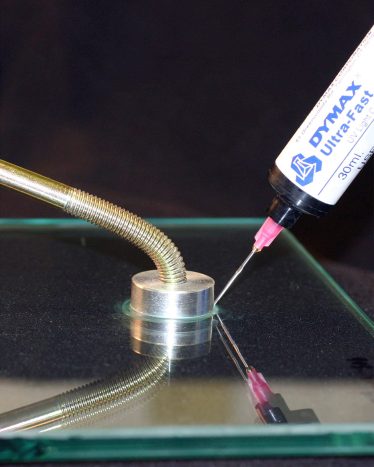

Dymax UV Curing Glass Bonding Adhesives cure in seconds upon exposure to UV and/or visible light from UV curing lamps. Additionally, Dymax Multi-Cure® grades cure with UV light, activator or heat even through UV blocked and tinted glass. These worker friendly resins form high strength, crystal clear, environmentally resistant bonds to glass as well as a variety of plastic and metal substrates. They adhere to soft glass, borosilicate glass, lead crystal, steel, plated metals and thermoset plastics. They are excellent adhesives for bonding stemware, glass headlamps, art glass, crystal figurines, trophies, architectural glass, novelties, metal brackets to glass and lens laminating.

Features & Benefits

- Single part, no mixing required

- Cure in seconds

- Bond to soft glass, borosilicate glass, lead crystal, steel, plated metals, and thermoset plastics

- High strength

- Crystal clear

- Environmentally resistant

- For decorative and industrial glass assembly

Applications

- Stemware

- Glass headlamps

- Fountain assembly and furniture assembly

- Art glass, architectural glass, and bulletproof glass

- Crystal figurines, trophies, and novelties

- Metal brackets to glass

- Laminating

Selector Guide

| Product | Application | Features |

|---|---|---|

| Dymax 429 DYM 429 |

Glass, plastic and metal bonding; glass laminating; bulletproof glass bonding; glass trophy assembly | Resists yellowing, vibration and thermal shock; optically clear; general purpose bonding, potting and sealing; for large area bonding |

| Dymax 431 DYM 431 |

High temperature and moisture resistant glass-to-metal bonding adhesive | Low shrinkage; UV/visible light-curable; LED curable; rapid bonding of glass and metal (stainless steel, aluminum, brass, and copper), wide variety of plastics such as ABS, CAP, PA, PC, PCTG, PEBA, PEEK, PET, PETG, PI, PVC, and SAN, as well as ceramic and FR4 |

| Dymax 6-621 DYM 6-621 Dymax 6-621-GEL DYM 6-621-GEL |

Glass/metal bonding to phenolic and filled plastics | High tensile strength; suited for rigid adhesive applications; clear, hard bonds; cures with UV light, heat or pre-applied activator |

| Dymax 401 DYM 401 |

Crystal assembly; glass furniture bonding; adhering metal brackets to glass | Excellent adhesion to glass and metal; low viscosity; very good moisture resistance; good for close fitting parts |

| Dymax 425 DYM 425 |

Glass stemware bonding; fountain assembly | Dishwasher safe; water clear; low viscosity; exceptional tensile strength; good vibration and impact resistance |

| Dymax 4-20418 DYM 4-20418 |

Bonding glass to acrylic; mirror assembly | Cures through UV blocked and tinted glass and plastics; resists yellowing in the sun; good performance during thermal cycling; low stress |

| Dymax 602-GEL-REV-A DYM 602-REV-A |

Bonding metal, steel and aluminium to glass | Cures with heat, light or pre-applied activator; tough, resilient bonds; can be used for coil terminating, unitising and tamper proofing adjustment screws |

Please request detailed product datasheets.

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

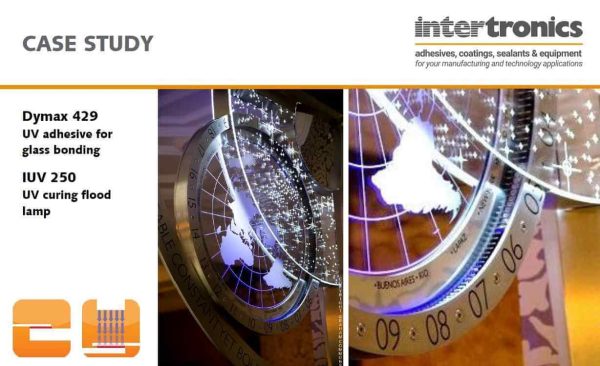

See how Dymax 429 works as part of a real application in this UV Curing Adhesive Case Study:

|

UV adhesive provides a virtually invisible bond for prestigious bespoke clock

A custom design clock benefits from the use of UV adhesive and curing equipment for a transparent bond line finish. |

- Last updated: July 2021

- Version: 7.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.