preeflow® eco-PEN XS Precision Volumetric Dosing Pump, for Repeatable Micro Dispensing

About preeflow® eco-PEN XS Precision Volumetric Dosing Pump, for Repeatable Micro Dispensing

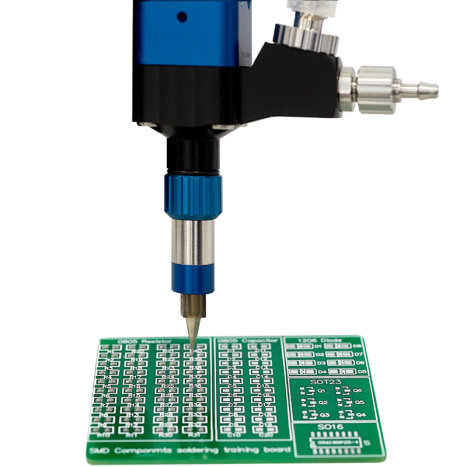

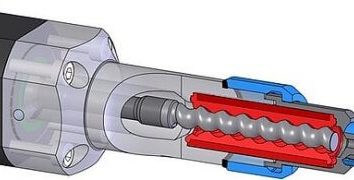

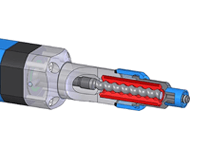

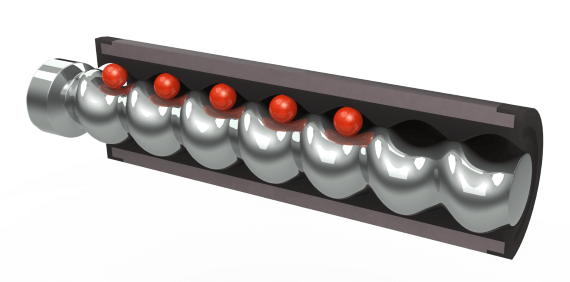

The preeflow eco-PEN XS is a precision volumetric, positive displacement, dosing/dispensing system capable of dispensing nano and microliter quanities of material accurately and repeatably. eco-PEN technology is based on the well established and proven preeflow progressive cavity pump principle, which enables true volumetric dispensing that is viscosity independent. The technology can dispense of a wide range of viscosities, from water-like substances up to thick pastes, including filled materials like solder paste, with low shear and no dripping.

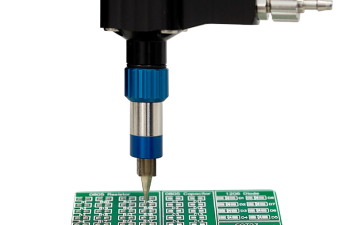

The eco-PEN XS is suitable for both line and dot dispensing, with bead widths starting from >0.1 mm, and an adjustable dispensing rate to suit the run speed. With accuracy of ±1%, >99% of the time, the device gives electronics and medical device assembly application specialists a reliable, repeatable tool for dispensing small liquid volumes.

The preeflow eco-PEN XS can be easily integrated into any of our robotic dispensing systems or other automation. Its lightweight design, weighing approximately 175 g, enables its use in high speed robotics, and the cartridge design means that several eco-PENs can be tightly spaced together in a narrow grid.

Features & Benefits

- Precise, process-stable dispensing as small as 0.00025ml (0.25μl)

- Highly repeatable and consistent dispensing, with an accuracy of ±1%, >99% of the time

- Gentle dosing of low viscosity to pasty liquids using positive displacement

- Linearly proportional control characteristics

- Controlled reverse suck-back for a cleaner process

- Easy system integration, including as part of our archytas series of robot integrations

Applications

The preeflow eco-PEN XS is designed for dot-dispensing, bead application with dispensing rate adjustable to the run speed, and encapsulation applications for:

- Solder paste

- Die-attach adhesives

- Edge-bond adhesives

- Electrically conductive adhesives

- Underfills

- Potting compounds

- Electronics packaging and encapsulation

- SMD/SMT

- Semiconductor

- LCD/LED

- Medical device assembly

- Biological chemistry

- Laboratory

- Photovoltaic

- Optics and photonics

Selector Guide

| Model | Smallest dose | Adjust flow rate | Weight |

|---|---|---|---|

| eco-PEN XS 180 | 0.00025 ml (0.25μl) | 0.0044 – 0.35 ml/min | 175g |

| eco-PEN300 | 0.001 ml (1μl) | 0.12 – 1.48 ml/min | 280g |

| eco-PEN330 | 0.002 ml (2μl) | 0.2 – 3.30 ml/min | 300g |

| eco-PEN450 | 0.004 ml (4μl) | 0.5 – 6.00 ml/min | 300g |

| eco-PEN600 | 0.015 ml (15μl) | 1.4 – 16.00 ml/min | 650g |

| eco-PEN700 | 0.060 ml (60μl) | 5.3 – 60.00 ml/min | 650g |

| eco-DUO330 For two part formulations |

0.005 ml (5μl) | 0.1 – 6.60 ml/min | 1230g |

| eco-DUO450 For two part formulations |

0.010 ml (10μl) | 0.2 – 12.00 ml/min | 1230g |

| eco-DUO600 For two part formulations |

0.030 ml (30μl) | 0.6 – 32.00 ml/min | 1880g |

Controllers

The eco-CONTROL EC200 2.0 control system provides total control of preeflow volumetric valves during the dispensing process. It’s designed for either benchtop or rack-mounted location, dependent on the model.

Operating principle

The unit is operated via a bright, 7” touch screen, making it simple to use. External signals can be connected via I/O ports to a PLC for control in automated lines. Up to 100 dosing programs, with part management can be stored locally.

Error messages for filling level and motor current are also monitored (an RS232 interface is provided).

It is possible to control two eco-PEN precision volume dosing units (as a factory-fit option).

Features

- Quantity and start/stop program

- Set-volume readout in g or ml

- Dosing flow readout in ml/min and g/min

- Storage of up to 100 dosing programs with part management

- Set pressure and actual pressure readings in bar/psi

Other Information

Helpful Resources

See the preeflow eco-PEN range as part of real applications in these dispensing and robotics Case Studies:

|

Automated dispensing helps security manufacturer increase throughput and quality

GJD Manufacturing switched to an automated method of dispensing silicone for sealing a plastic lens to aluminium housing. By doing this, they improved the throughput and quality of their white-light and infra-red LED illuminators for the security industry. |

|

Precision dispensing helps electrical manufacturer to reduce waste by improving quality and yield

By switching to an automated dispensing system, this electrical manufacturer reduced scrappage and therefore improved quality and yield of their product. |

See also our Technical Articles and White papers page for the following white paper and more:

The “Endless Piston” Pump – Technology for Precision Dispensing by Peter Swanson |

Precise Dispensing of Two-Part Materials by Paul Whitehead |

Ordering Information

| Part number | Description |

|---|---|

| VIS176836 | preeflow eco-PEN180 XS |

| VIS20505 | preeflow eco-PEN300 |

| VIS21529 | preeflow eco-PEN330 |

| VIS20092 | preeflow eco-PEN450 |

| VIS20048 | preeflow eco-PEN600 |

| VIS20723 | preeflow eco-PEN700 |

| VIS21529 | preeflow eco-DUO330 |

| VIS20639 | preeflow eco-DUO450 |

| VIS21175 | preeflow eco-DUO600 |

| VIS22402 | preeflow eco-CONTROL EC200-2.0 |

| VIS20326 | preeflow eco-REMOTE 232 port for external channel selection |

| VIS20143 | preeflow eco-PEN stand |

Let’s start by talking about your application

- Last updated: December 2023

- Version: 1.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.